A kind of manufacturing method of Invar alloy foil

A technology of Invar alloy and manufacturing method, which is applied in the field of Invar alloy foil manufacturing, can solve the problems of reducing production efficiency and yield rate, environmental pollution, product performance fluctuations, etc., to improve production efficiency and yield rate, and simplify preparation process, the effect of avoiding cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

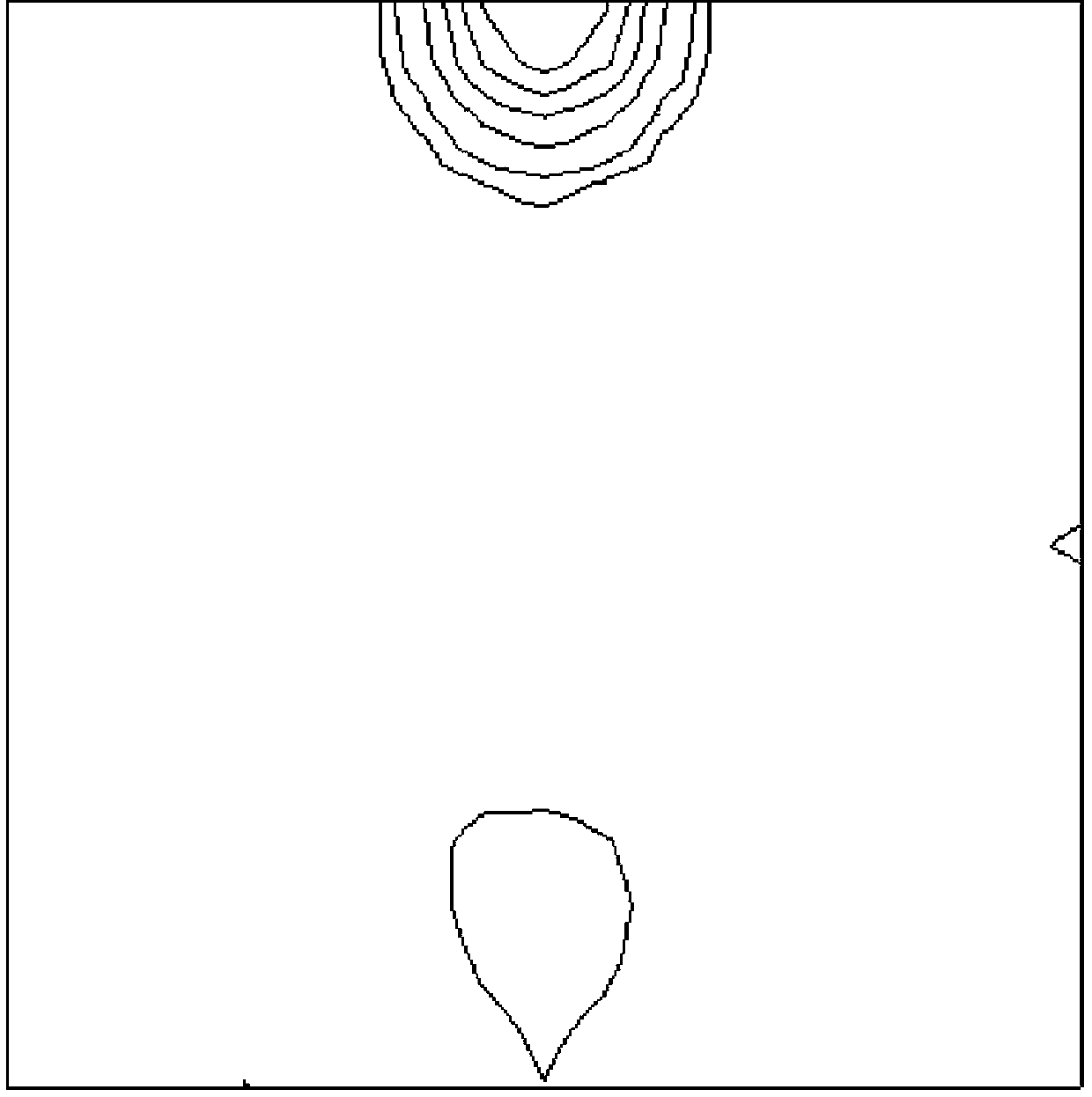

[0038] Process such as figure 1 shown;

[0039] The molten steel is smelted in an intermediate frequency vacuum induction furnace, and the smelted molten steel is poured through the tundish into a cavity composed of two crystallization rollers and two side sealing plates by using a twin-roller thin strip continuous casting device to form a molten pool. The molten steel solidifies with the rotation of the crystallization roller and is exported at a speed of 20m / min to make an Invar alloy cast belt, the composition of which is Ni 35%, C0.005%, Si 0.1%, Mn 0.2%, S 0.01% by mass percentage , P 0.01%, the balance is Fe and unavoidable impurities; Invar cast strip thickness 3mm;

[0040] The cast strip of Invar alloy is water-cooled to room temperature by the cooling unit at a cooling rate of 10-100°C / s to obtain a cast strip at room temperature;

[0041] The room temperature cast strip is pickled to remove the surface oxide scale, and then a cold rolling is performed, and the red...

Embodiment 2

[0045] Method is with embodiment 1, and difference is:

[0046](1) The composition of Invar cast strip is Ni 37.5%, C 0.5%, Si 0.6%, Mn 0.8%, Ti 2.5%, Al 1.0%, S 0.01%, P 0.01%, Zr 0.1%, Rare earth element 0.2%; Invar alloy casting strip thickness 2.5mm; export speed 60m / min during continuous casting;

[0047] (2) The reduction rate of primary cold rolling is 75%; the intermediate annealing temperature is 800°C, and the time is 20 minutes; the reduction rate of secondary cold rolling is 96.8%.

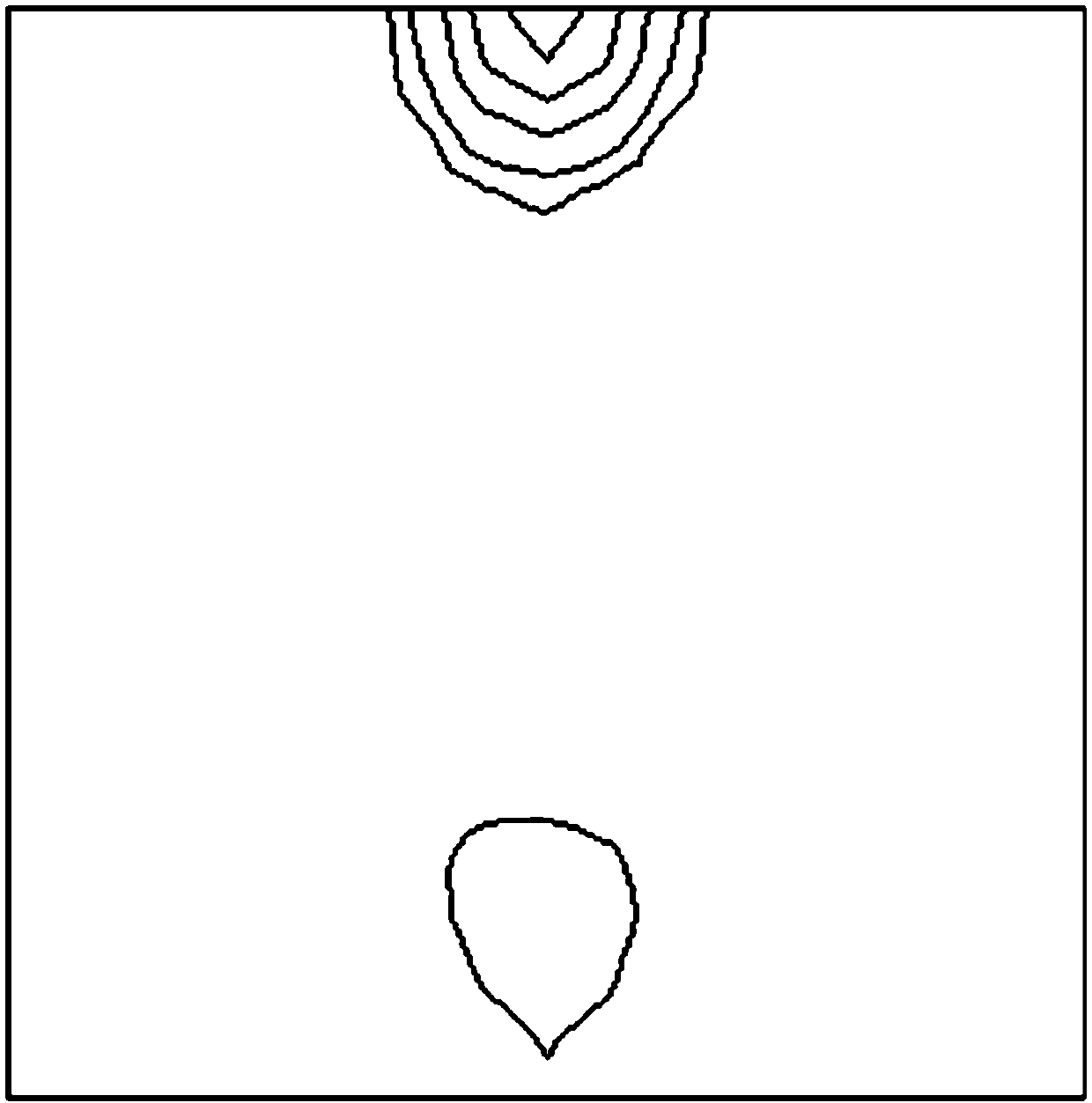

[0048] (3) The final annealing temperature is 900°C, the time is 20min, the thickness of the Invar alloy foil is 0.02mm, and its texture is a strong cubic texture ({001} preferred orientation), such as Figure 4 shown;

[0049] Adjust the process steps and carry out the comparison test according to the above method. After pickling, it is directly cold-rolled to 0.02mm, that is, the cold-rolling reduction rate is 99.2%. The intermediate annealing is canceled, and the texture of the fi...

Embodiment 3

[0051] Method is with embodiment 1, and difference is:

[0052] (1) The composition of Invar cast strip is Ni 36%, C 0.3%, Si 0.3%, Mn 0.4%, Ti1.5%, Al 0.5%, S 0.02%, P 0.01%, Zr 0.06% in mass percentage ; Invar casting strip thickness 5mm; export speed 30m / min during continuous casting;

[0053] (2) The reduction rate of primary cold rolling is 80%; the intermediate annealing temperature is 700°C, and the time is 30 minutes; the reduction rate of secondary cold rolling is 90%.

[0054] (3) The final annealing temperature is 800°C, the time is 10min, the thickness of the Invar alloy foil is 0.1mm, and its texture is a strong cubic texture ({001} preferred orientation);

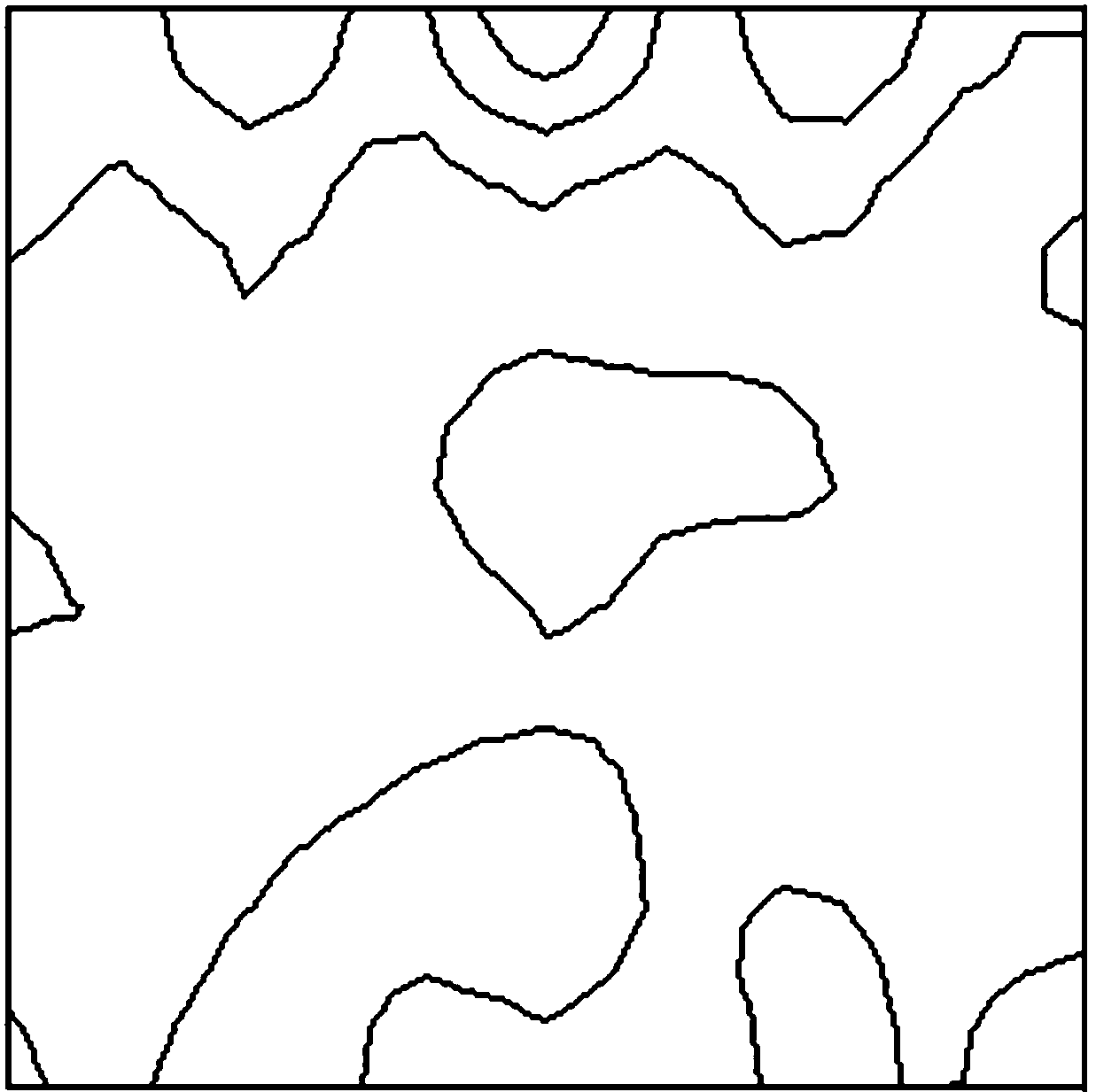

[0055] Adjust the composition of the molten steel and conduct a comparative test according to the above steps. The composition of the ingot contains Ni 32.0%, C0.1%, Si 0.3%, and Mn 0.9% by mass percentage; the texture of the final annealed plate obtained is diffuse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com