Telescopic steel reinforcement cage, compression equipment thereof and method for constructing cast-in-situ bored pile

A steel cage and telescopic technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as high labor costs and shift costs, poor integrity of steel cages, and reduced pile quality, and achieve strong integrity. , good strength and bearing capacity, ensure the effect of pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

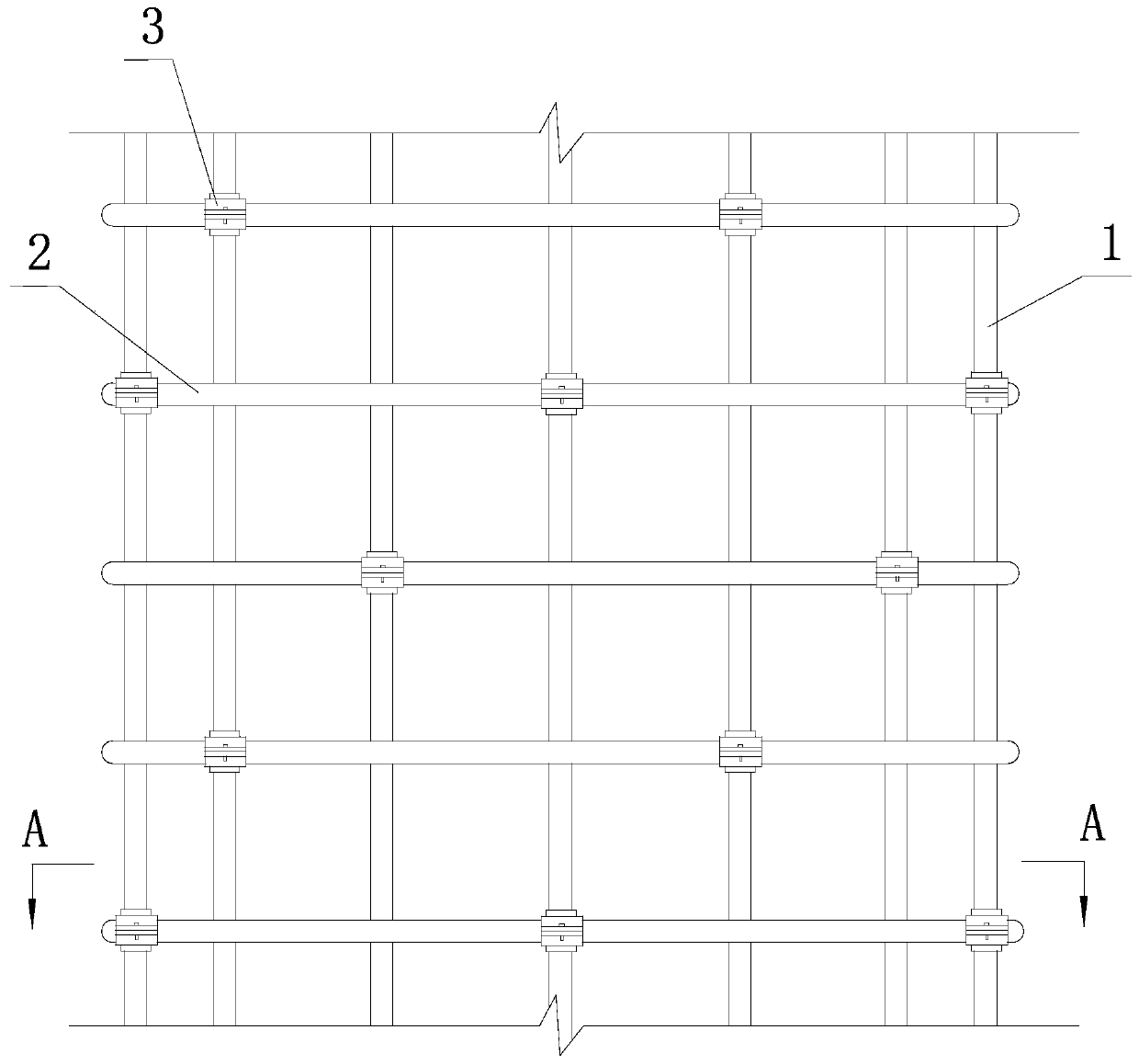

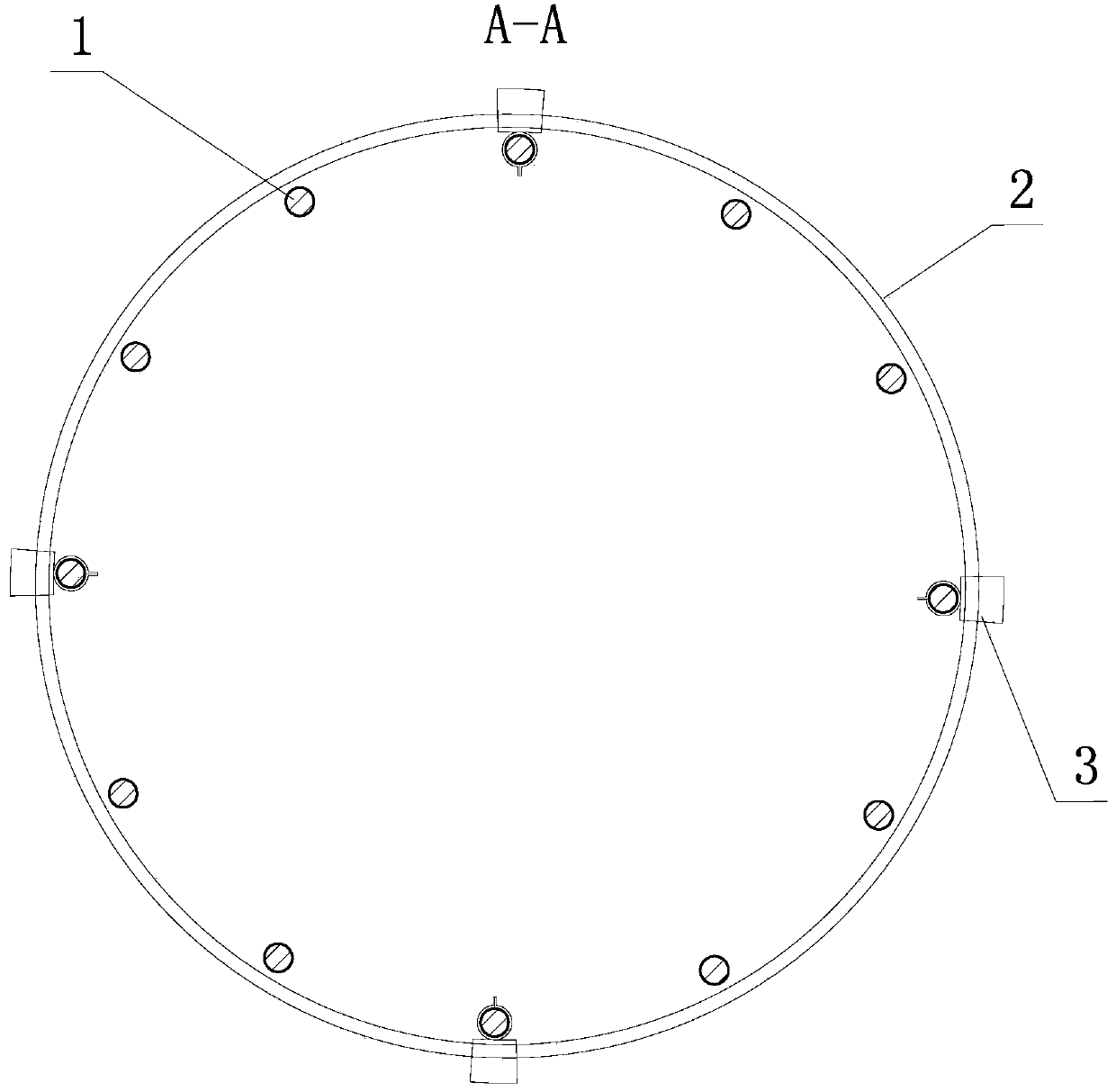

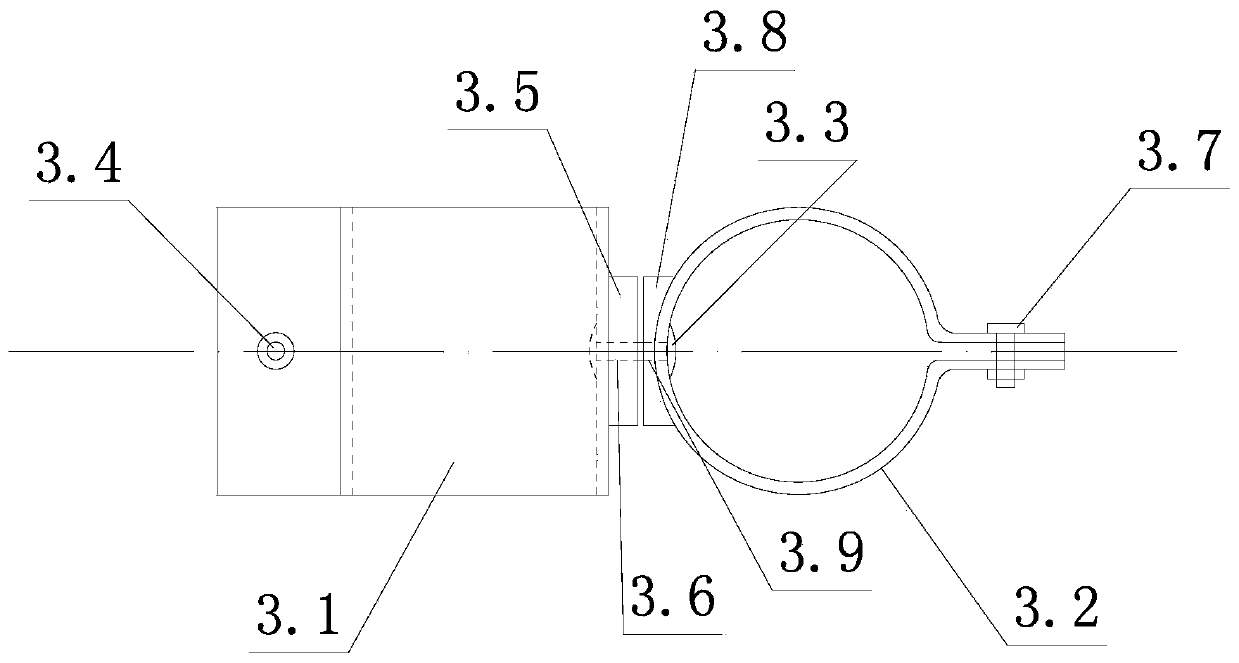

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, the telescopic reinforcement cage of the present invention includes a longitudinal reinforcement 1 and an annular stirrup 2, each longitudinal reinforcement 1 is formed by twisting multiple strands of steel strands, and the longitudinal reinforcement 1 and the stirrup 2 are connected by a fastener 3 connect. Each connecting fastener 3 includes an inner jacket 3.1 fixed with a single longitudinal rib 1, an outer jacket 3.2 fixed with a single stirrup 2, and a rotatably connected inner jacket 3.1 and outer jacket 3.2. rivets 3.3. Specifically, the inner side of the inner jacket 3.1 is provided with an inner opening for the longitudinal rib 1 to squeeze in, and the inner opening is locked by the inner bolt 3.4, and the outer side of the inner jacket 3.1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com