Double-layer water well pipe with filtering structure

A technology of filtering structure and water well pipe, applied in water saving, water supply device, drinking water device, etc., can solve problems such as damage, quicksand, piping, road subsidence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

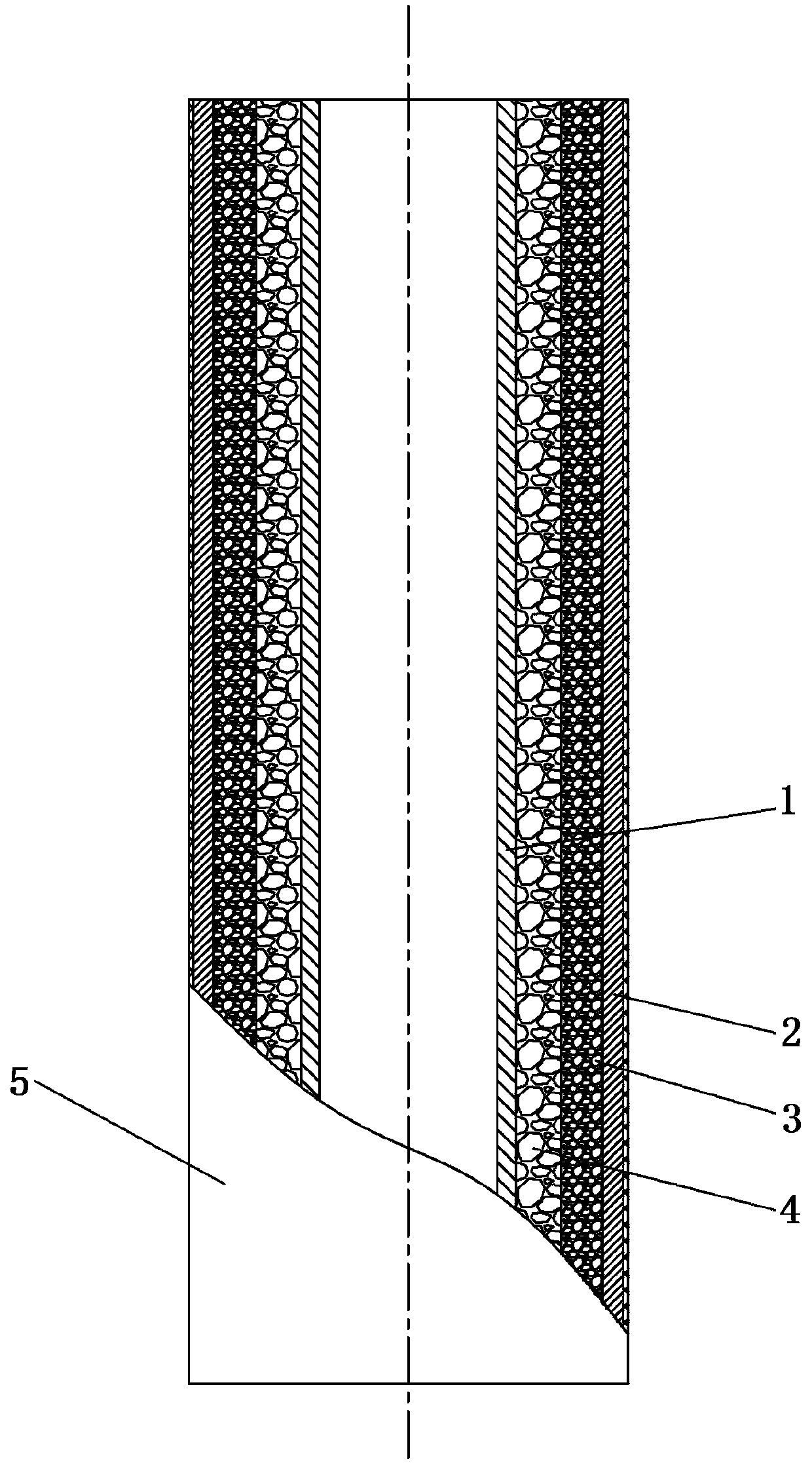

[0009] A double layer water well pipe with filtering structure, such as figure 1 As shown, including the pipe body, the pipe body is composed of a water seepage outer pipe 2 and a water seepage inner pipe 1 coaxially spaced together. through hole. The pipe wall of the water seepage outer pipe 2 is set with a non-woven filter screen 5, and the through holes evenly arranged on the pipe walls of the water seepage inner pipe 1 and the water seepage outer pipe 2 have a diameter of no more than 1mm. The water seepage inner pipe and the water seepage outer pipe The small pebble gravel layer 4 and the medium-coarse sand layer 3 are respectively arranged in the annular space between them from the inside to the outside, and the small pebble gravel layer 4 and the medium-coarse sand layer 3 are arranged in a coaxial cylindrical structure. The particle size of the medium-coarse sand in the sand layer 3 is 0.25-1.5 mm, and the particle size of the pebble gravel 4 is 1-4 mm.

[0010] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com