Encapsulation method of one-time pouring of large-diameter steel pipe concrete

A technology of steel pipe concrete and reinforced concrete, which is applied in construction, pipeline laying and maintenance, pipes/pipe joints/fittings, etc. It can solve problems such as steel pipe displacement, construction quality not guaranteed, and difficulty in completing construction tasks according to schedule. Achieve the effect of saving construction period and cost, benefiting concrete quality control, ensuring strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

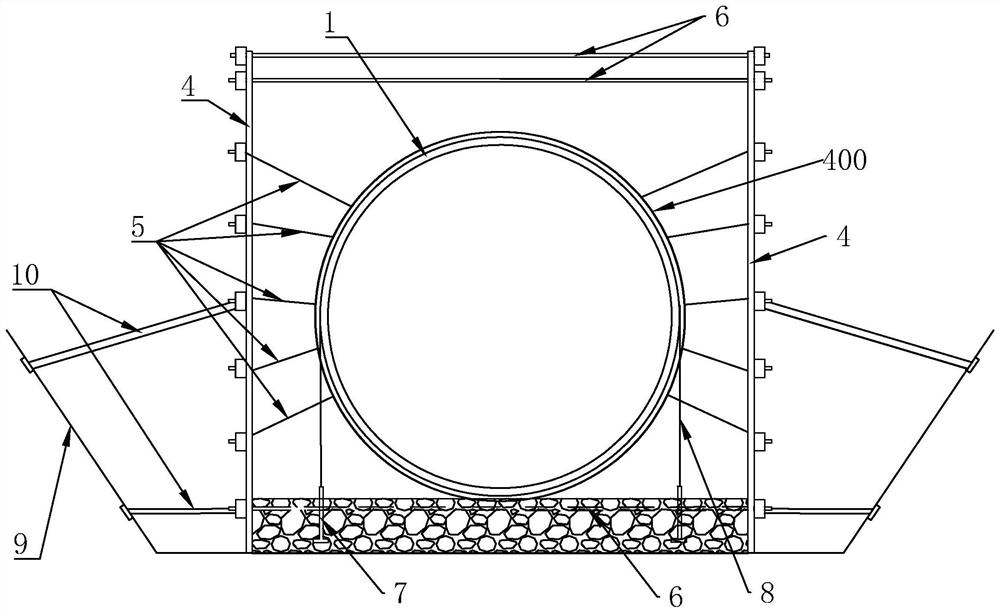

[0036] Such as Figure 1-4 As shown, it is a one-time pouring large-diameter steel pipe concrete encapsulation method disclosed by the present invention, comprising steps:

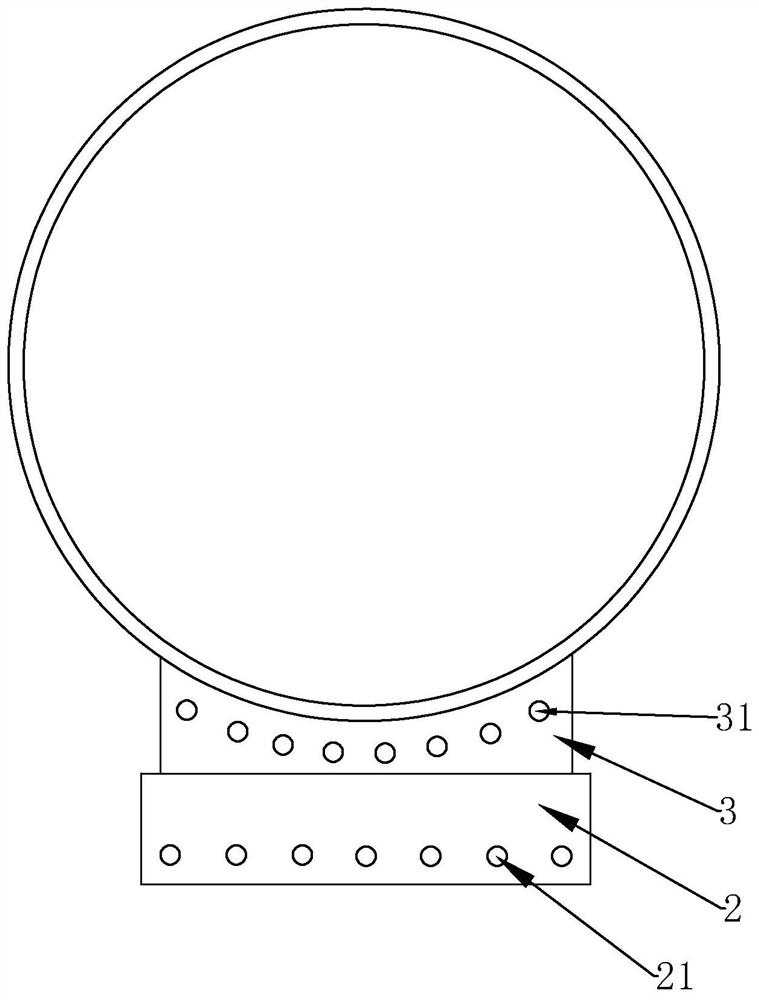

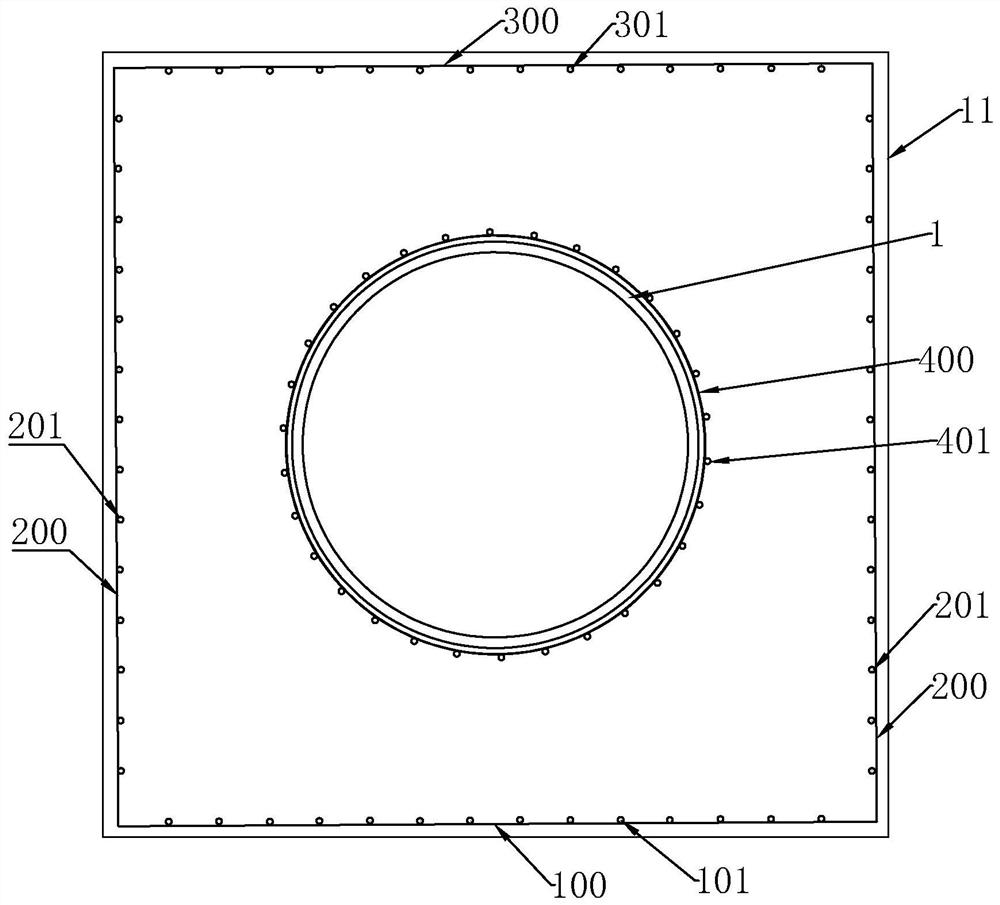

[0037] 1) Pouring of reinforced concrete support 2 and installation of arc-shaped support 3: multiple reinforced concrete supports 2 are poured along the axial direction of the preset steel pipe 1, and the reinforced concrete support 2 is a cuboid, and the lower part of each reinforced concrete support 2 A plurality of lower horizontal bars 100 perpendicular to the axis of the steel pipe are pre-embedded, and a plurality of hollow tubes 21 for piercing the lower longitudinal bars 101 are pre-embedded in the lower part of the reinforced concrete support 2. The hollow tubes are made of PVC pipes. 2 After drying to meet the design requirements, the top surface of the reinforced concrete sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com