Infrasound sensor and realizing method thereof

A sensor, acceleration sensor technology, used in the measurement of ultrasonic/sonic/infrasonic waves, instruments, seismic signal receivers, etc., can solve problems such as interference, high cost, and complex use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

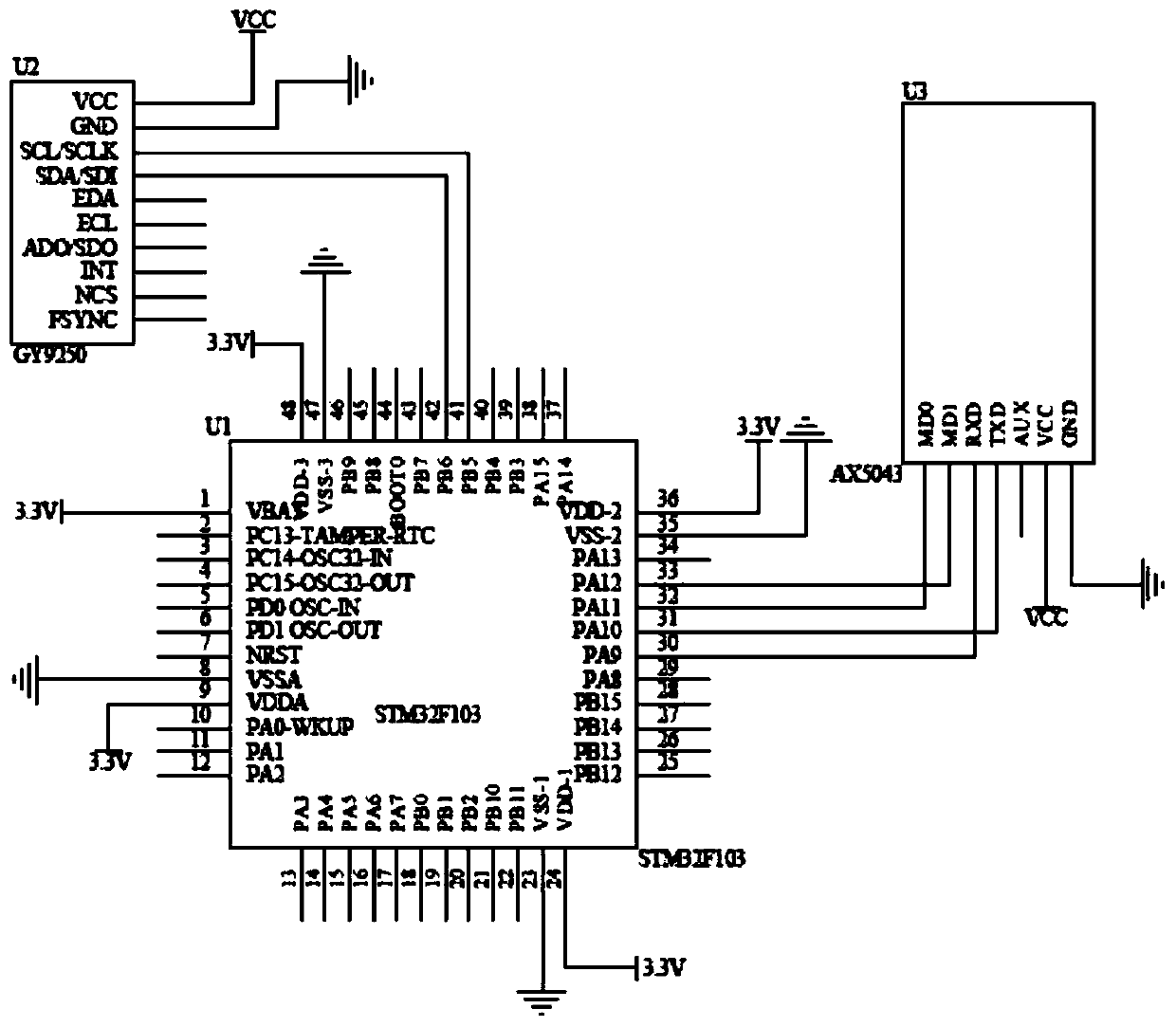

[0058] Embodiment 1: as Figure 1-2 As shown, an infrasound sensor includes a plastic shell 1, a single-chip microcomputer 2, and an acceleration sensor 3; wherein the acceleration sensor 3 is connected to the single-chip microcomputer 2, and the acceleration sensor 3 and the single-chip microcomputer 2 are hermetically packaged through the plastic shell 1 and buried in the ground. The plastic shell 1 Adopt airtight and waterproof strong plastic shell.

[0059] Further, the acceleration sensor 3 adopts the MPU-9250 nine-axis sensor.

[0060] Further, the acceleration sensor 3 is connected to the single-chip microcomputer 2 through i2c communication, and the single-chip microcomputer 2 adopts STM32F103; wherein, the SCL port of the MPU-9250 is connected to the PB5 port of the single-chip microcomputer 2, the SDA port is connected to the PB6 port of the single-chip microcomputer 2, and the VCC port is connected to the power supply VCC , the GND port is grounded.

[0061]The MP...

Embodiment 2

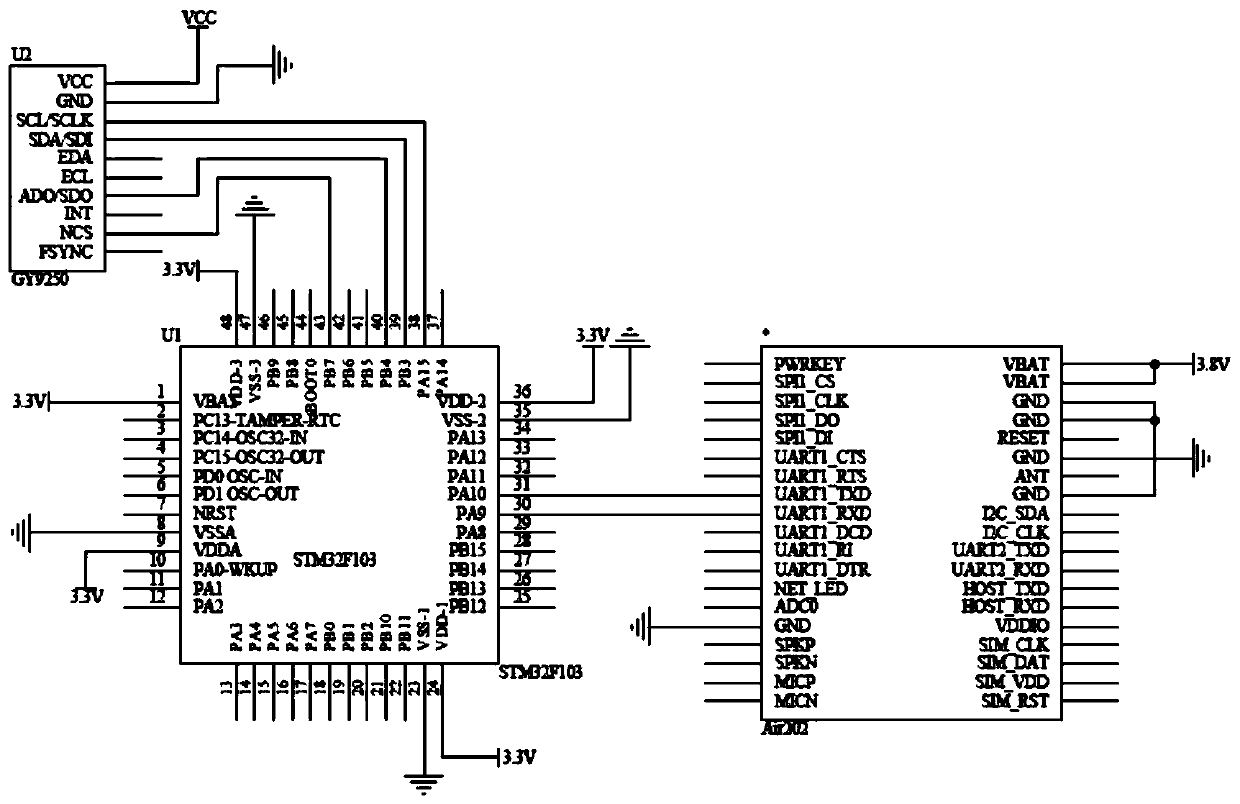

[0084] Embodiment 2: as figure 1 , image 3 As shown, a kind of infrasound sensor and its implementation method, this embodiment is the same as embodiment 1, and wherein difference is:

[0085] Further, the acceleration sensor 3 is connected to the single-chip microcomputer 2 through SPI communication, and the single-chip microcomputer 2 adopts STM32F103; wherein, the SCLK port of the MPU-9250 is connected to the PA15 port of the single-chip microcomputer 2, the SDI port is connected to the PB3 port of the single-chip microcomputer 2, and the SDO port is connected to the single-chip microcomputer 2 The PB4 port of the MCU, the NCS port is connected to the PB7 port of the microcontroller 2, the VCC port is connected to the power supply VCC, and the GND port is grounded.

[0086] The MPU-9250 nine-axis sensor (U2) communicates with the MCU 2 (U1) through two data lines, a chip selection signal line and a clock line. When there are two MPU-9250 nine-axis sensors, you only need ...

Embodiment 3

[0088] Embodiment 3: as Figure 1-3 As shown, a kind of infrasound sensor and its implementation method, this embodiment is the same as embodiment 1, and wherein difference is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com