Preparation method of solid-state thin-film fuel cell

A fuel cell and thin film technology, applied in the field of preparation of solid-state thin film fuel cells, can solve the problems of low space utilization rate, low volume energy density, small reaction interface of thin film fuel cells, etc., so as to improve space utilization rate and reduce space size, The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

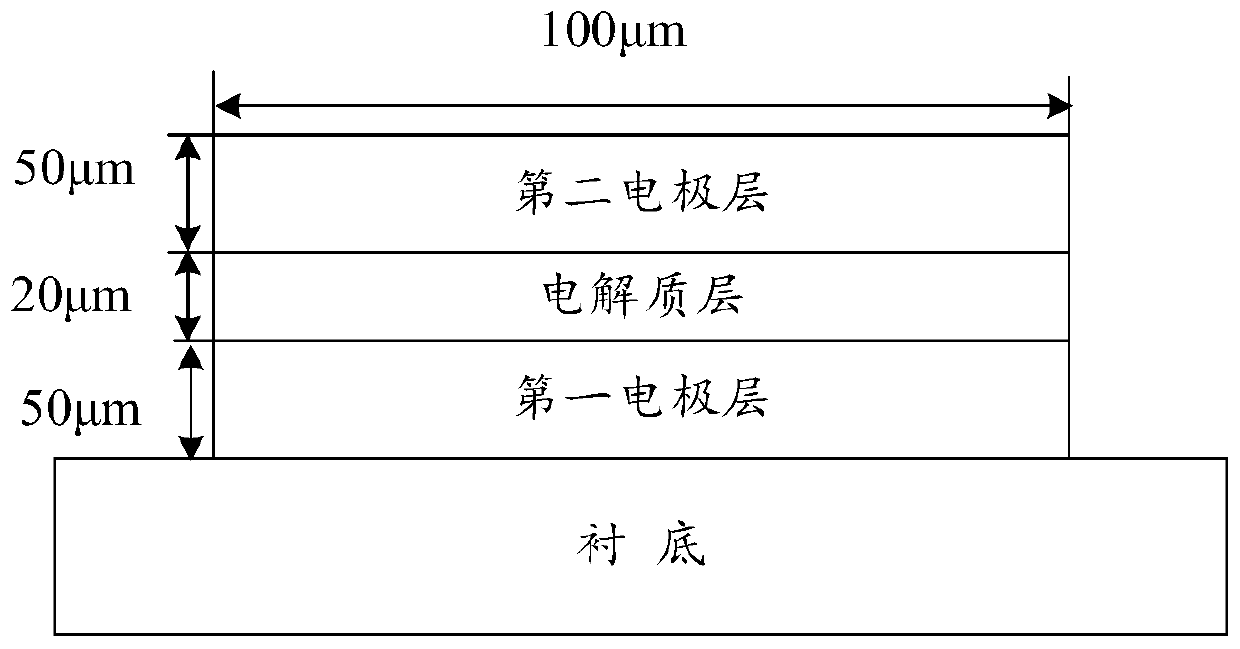

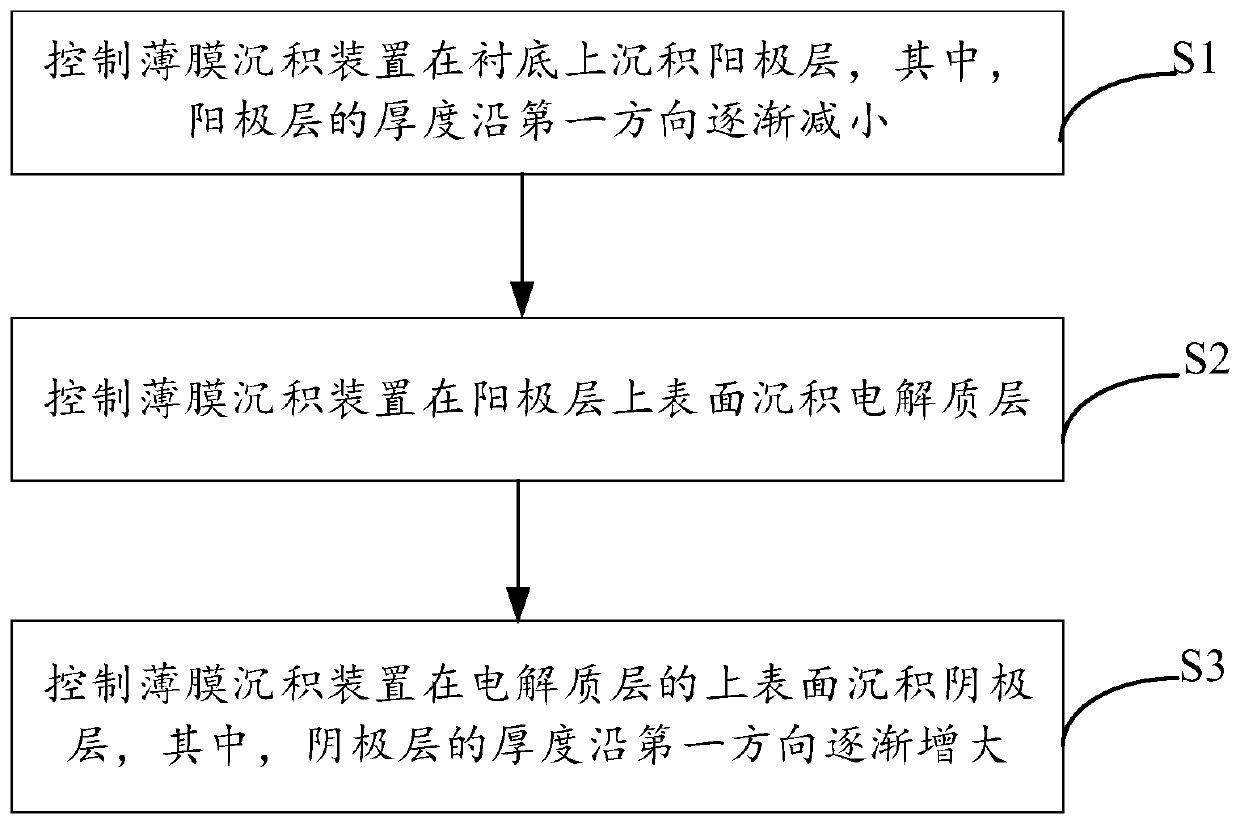

[0045] The embodiment of the present invention proposes a preparation method of a solid thin film fuel cell, please refer to figure 2 Shown, the preparation method of this solid membrane fuel cell comprises the following steps:

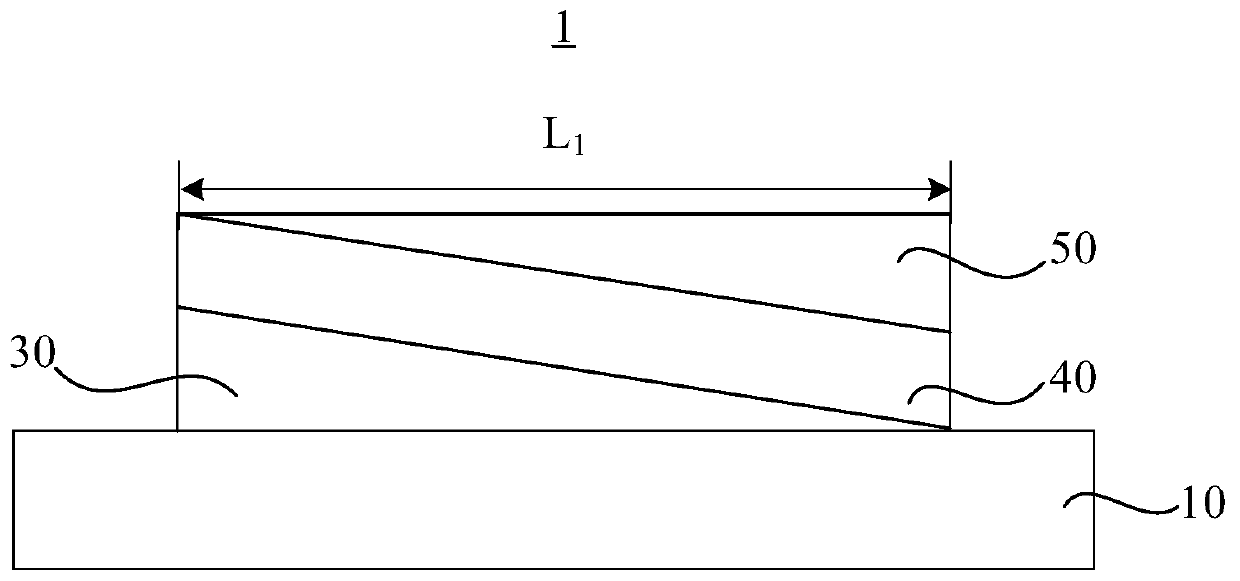

[0046] S1. controlling the thin film deposition device to deposit a first electrode layer on the substrate, wherein the thickness of the first electrode layer gradually decreases along the first direction;

[0047] S2. controlling the thin film deposition device to deposit an electrolyte layer on the surface of the first electrode layer;

[0048] S3. Controlling the thin film deposition device to deposit a second electrode layer on the upper surface of the electrolyte layer, wherein the thickness of the second electrode layer gradually increases along the first direction.

[0049]Wherein, the first electrode layer is one of the anode layer and the cathode layer, and the second electrode layer is the other of the anode layer and the cathode layer. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com