Three-degree-of-freedom motor with double-stator structure

A technology with a degree of freedom and double stators, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of increased motor cost, slow response speed, low operating accuracy, etc., to achieve increased accuracy and response The effect of fast speed and high running precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

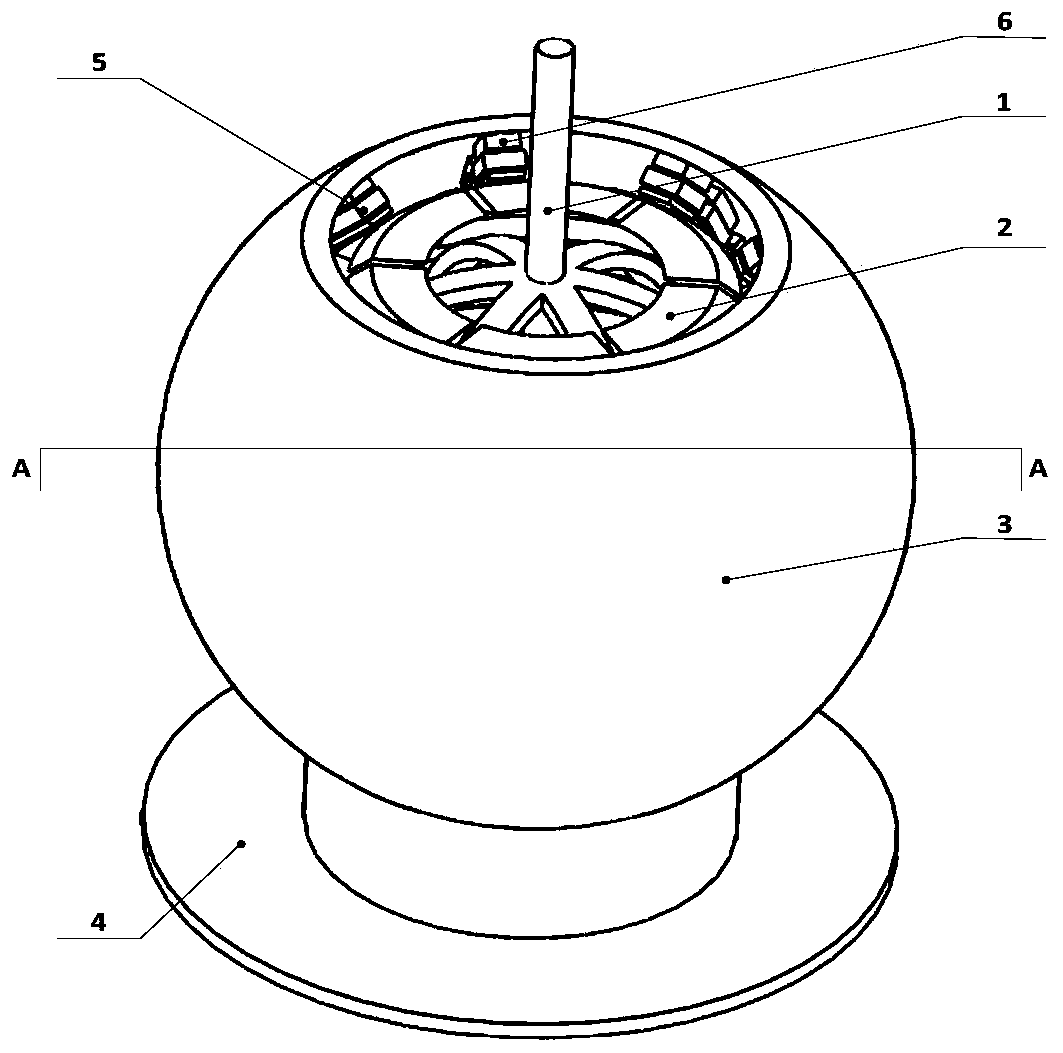

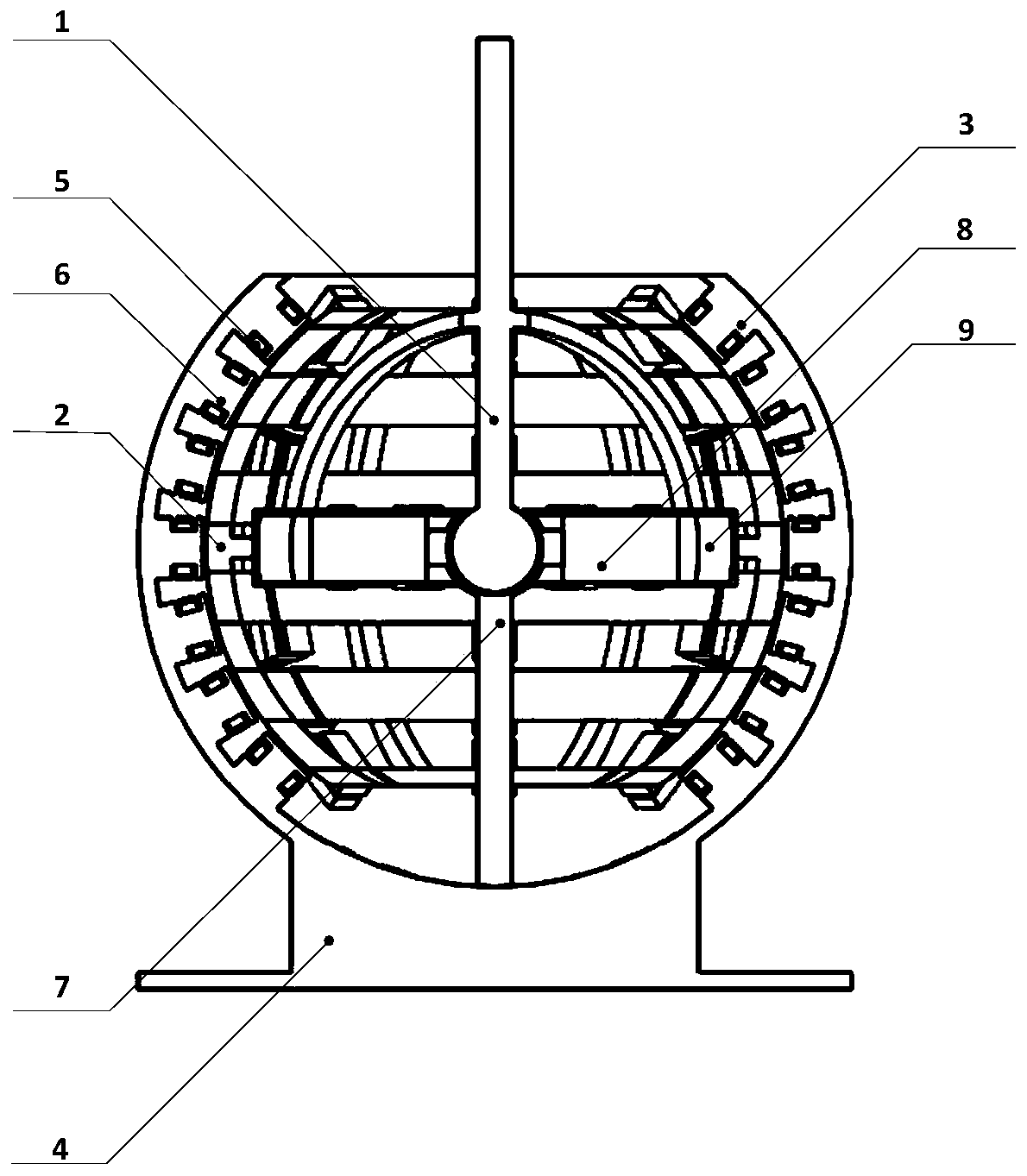

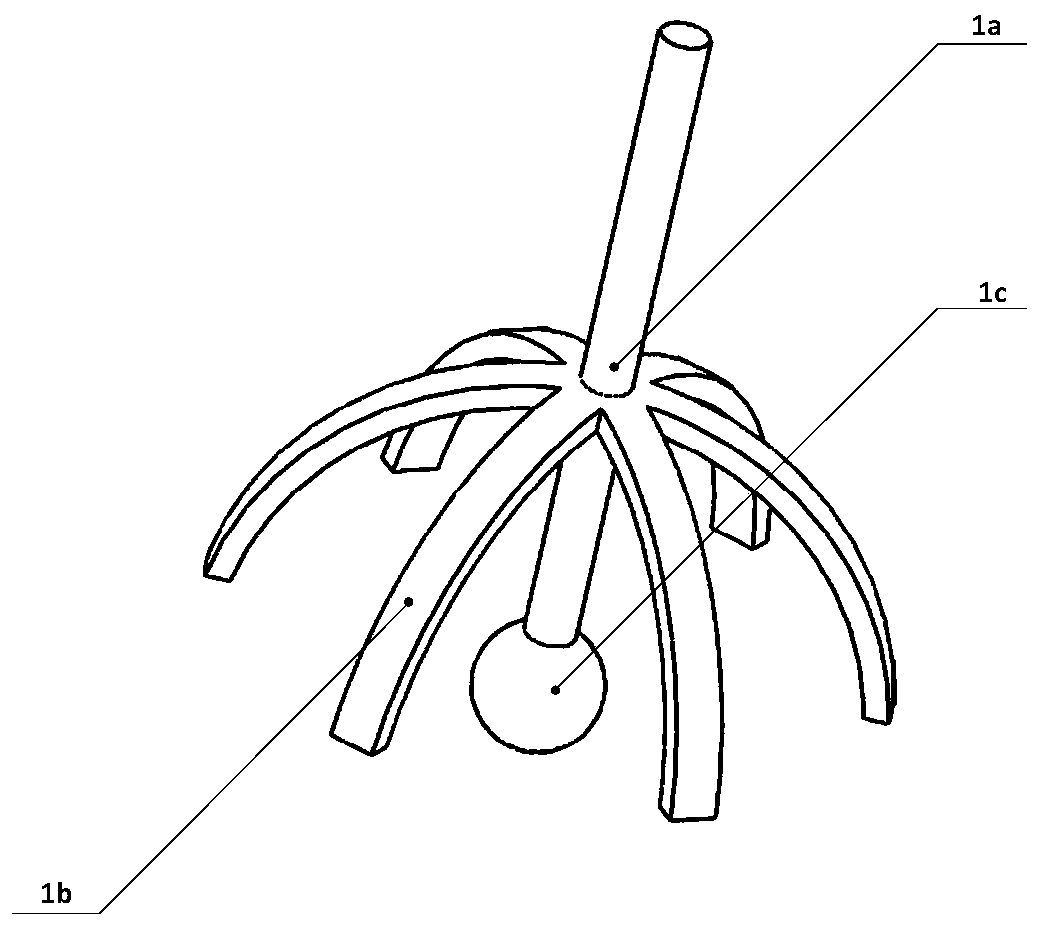

[0035] See attached picture. The present invention will now be described. As a specific embodiment provided by the present invention, the three-degree-of-freedom motor with a double-stator structure includes: a housing, an outer stator 3, and is characterized in that it also includes an inner stator 8 and a rotor with a composite structure. , the composite structure rotor is located between the outer stator 3 and the inner stator 8; the inner stator 8 is fixed on the fixed shaft 7, and the lower end of the fixed shaft 7 is fixed on the casing 3; the output shaft 1 is fixed on the composite structure rotor, and the lower end of the output shaft 1 It is connected with the fixed shaft 7 through movable bearings; a number of deflection coil yokes 6 are distributed on the inner side of the outer stator 3, and a plurality of magnetic poles are distributed on the outer side of the composite structure rotor, and the deflection driving coil 5 of the outer stator 3 inner side deflection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com