Electrostatic-piezoelectric-electromagnetic composite energy harvester

A piezoelectric energy harvesting, composite technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of low output power, low conversion efficiency, difficult to meet Problems such as the electricity demand of low-power electronic products, to achieve the effect of increasing the power generation current, low maintenance costs, and saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

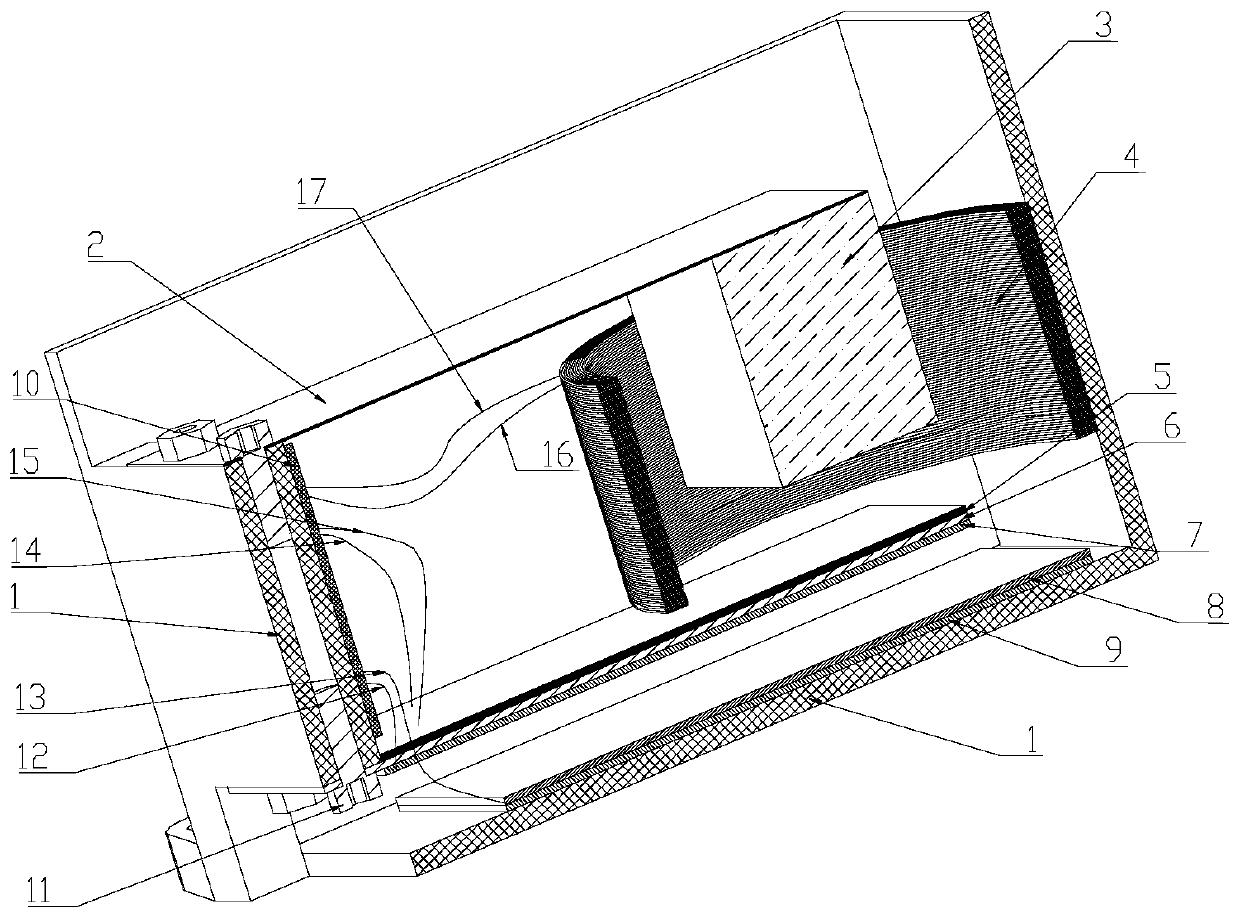

[0043] See figure 1 , Piezoelectric-electrostatic-electromagnetic composite energy harvester includes: shell 1, low-frequency beam 2, magnet 3, toroidal coil 4, piezoelectric ceramic material 5, high-frequency beam 6, upper electrode 7, electret 8, lower electrode 9. Circuit board 10, bolt 11, upper electrode lead 12, lower electrode lead 13, piezoelectric sheet positive lead 14, piezoelectric sheet negative lead 15, coil positive lead 16, coil negative lead 17;

[0044] The low-frequency beam 2 is fixed on the shell 1 by one end of the bolt 11, and a magnet 3 is attached to the bottom of the other end. The toroidal coil 4 is placed horizontally inside the shell 1 and fixed in contact with the three inner walls of the shell 1. The upper end of the coil 4 and the low-frequency beam 2 have a gap , There is a gap between the lower end and the piezoelectric ceramic material 5.

[0045] One end of the high-frequency beam 6 is fixed to the housing 1 by bolts, the piezoelectric ceramic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com