Double-layer filter with flow limiting device

A technology of double-layer filter and flow limiting device, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of injection molding difficulty, difficulty, and high cost, and achieve quality control with low difficulty and high cost. The effect of reliable function and guaranteed life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

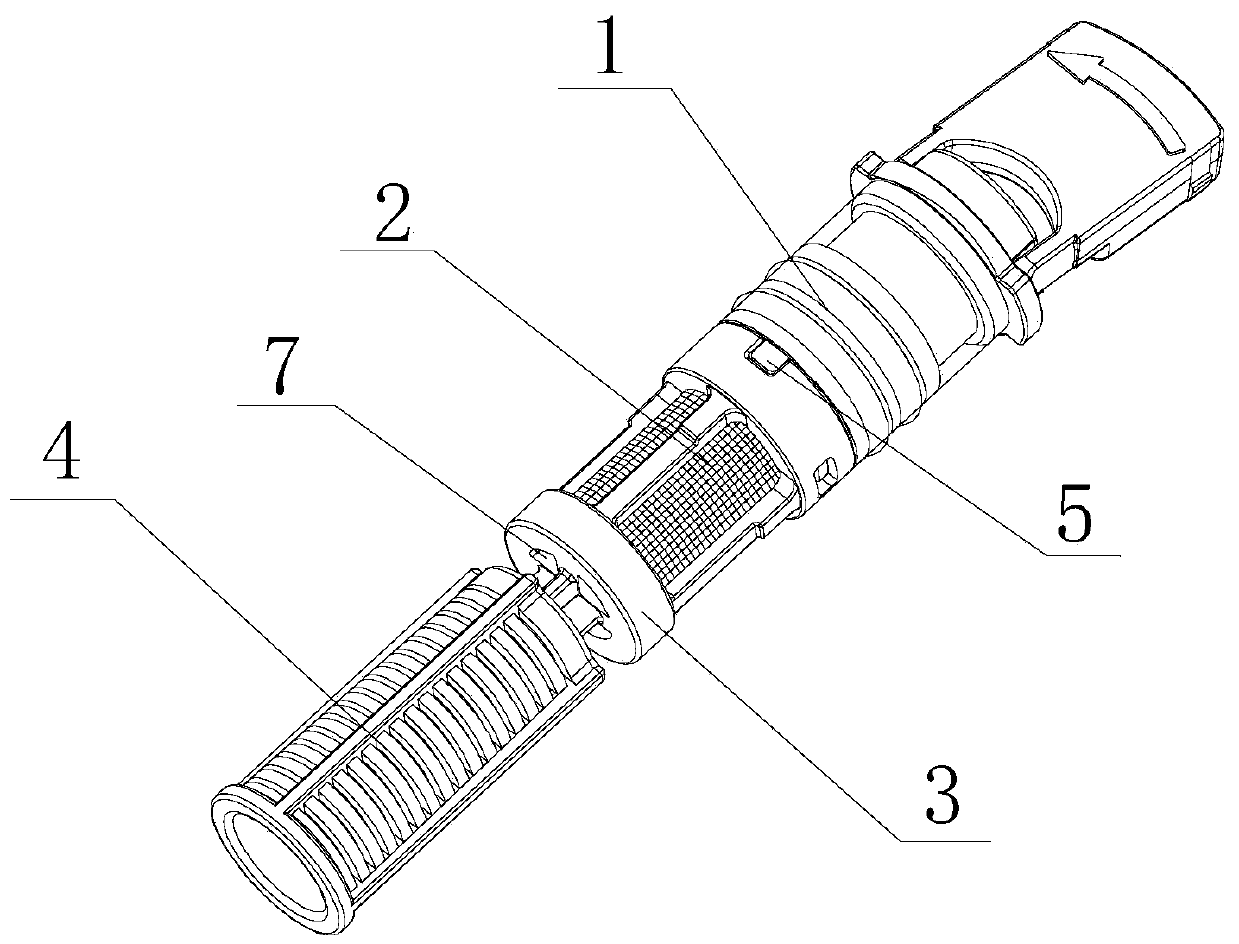

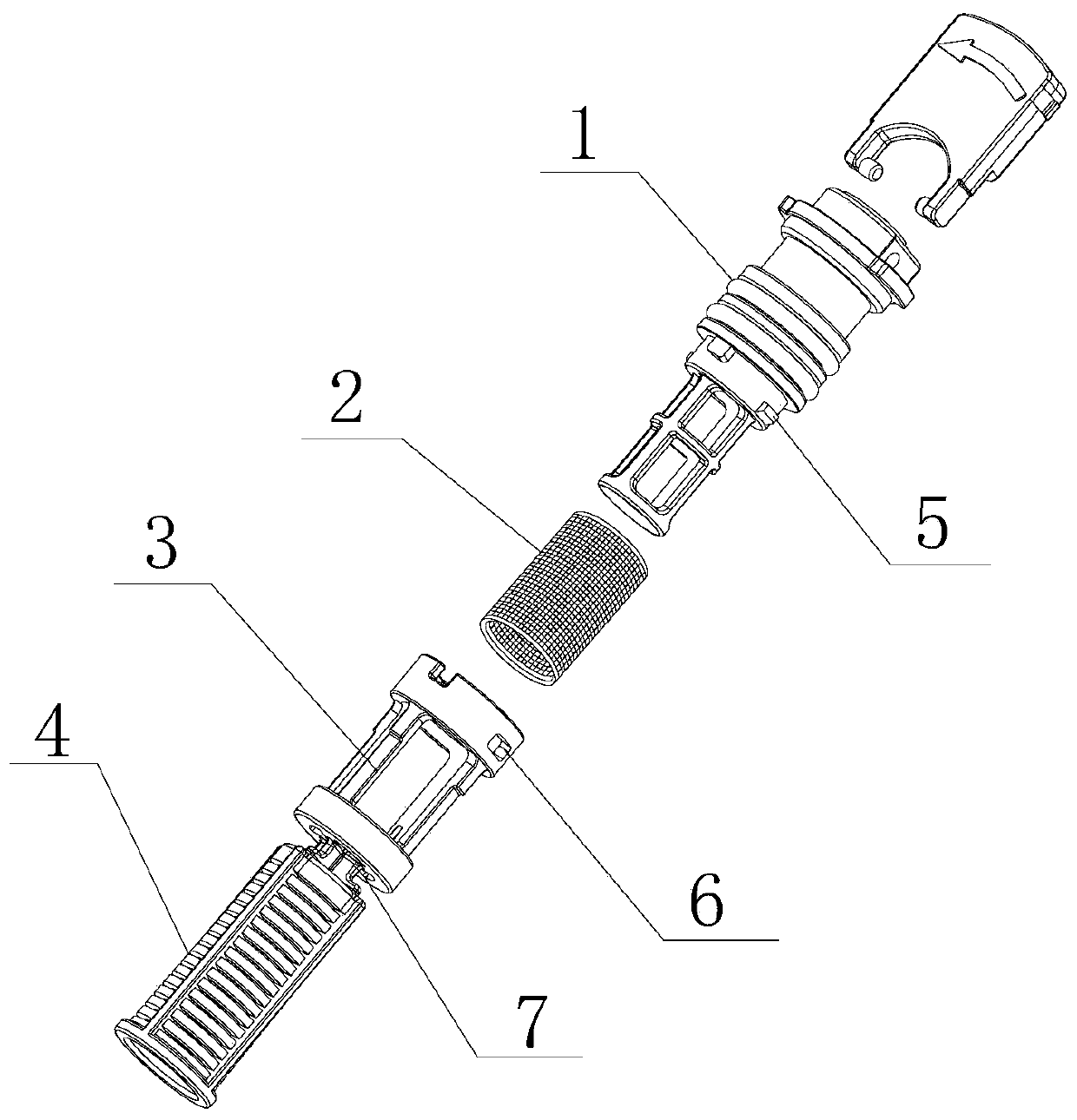

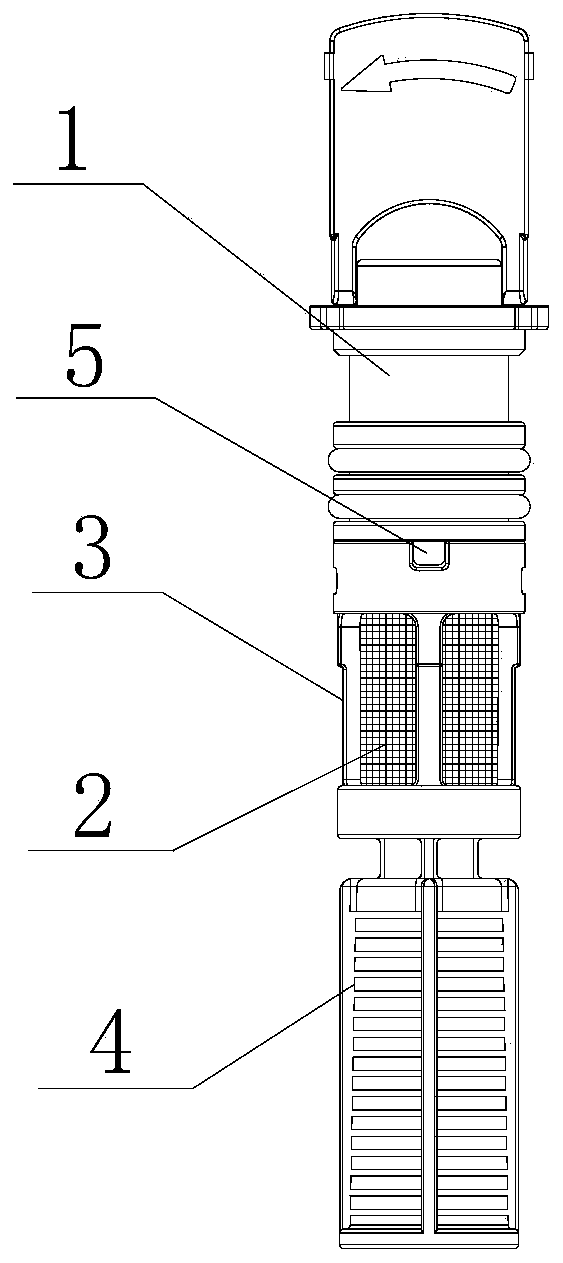

[0022] A double-layer filter with a flow limiting device, comprising a filter upper body 1, a stainless steel fine filter 2, a filter lower body 3, a plastic coarse filter 4, a buckle 5, a buckle hole 6, and a flow limiting channel 7. The stainless steel fine filter 2 is placed in the cavity above the filter lower body 3, and the outside of the bottom of the filter upper body 1 is provided with a buckle 5, which can be used as a guarantee for the fastening of the filter upper body 1 and the stainless steel fine filter 2. The outer side of the upper end of the filter lower body 3 is provided with a buckle hole 6, and the buckle hole 6 and the buckle 5 are mutually fitted, and the filter upper body 1 and the filter lower body 3 pass through the buckle 5 and the buckle hole on both sides 6 fastening connection, the top of the plastic coarse filter 4 is provided with a filter lower body 3, and a flow-limiting channel 7 is set between the bottom of the filter lower body 3 and the pl...

Embodiment 2

[0028] A double-layer filter with a flow limiting device. A rubber ring 8 is added between the front channel 71 and the plastic coarse filter 4. When the water pressure is low, the extrusion deformation of the rubber ring 8 is small, and finally The area of the channel 72 remains unchanged, and the flow rate is not affected. When the water pressure is high, the water pressure impacts the rubber ring 8 and moves upward, and the rubber deforms and squeezes to the small hole of the final channel 72, and the area decreases, thereby reducing the flow rate. Under the strong water pressure of 1.6Mpa and 2.0Mpa, the flow rate can basically be maintained between 0.33L-0.5L / s, so as to protect the water inlet valve and prolong the service life.

[0029] The present invention provides a double-layer filter with a flow limiting device through improvement, and its working principle is:

[0030] First, the water flow enters the interior of the plastic coarse filter screen 4, and the water...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap