Integrated medicine raw material crushing device

A raw material crushing and integrated technology, which is applied in the field of medical devices, can solve the problems of increasing raw material loss, reducing production efficiency, and low integration, achieving high processing efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

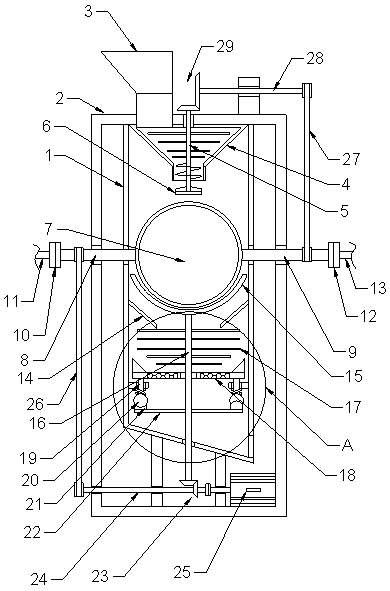

[0020] see figure 1 , in the embodiment of the present invention, an integrated pharmaceutical raw material crushing device includes a processing cylinder 1 and a bracket 2 fixedly connected with the processing cylinder 1; the upper end of the processing cylinder 1 is connected with a feeding hopper 3, and the processing cylinder 1 is nested with a The preliminary crushing box 4 connected to the feeding hopper 3 is provided with a crushing blade roller 5 inside the preliminary crushing box 4, and the crushing blade roller 5 performs preliminary crushing on the medical raw materials; The lower end is provided with a drying ball 7. The drying ball 7 is a hollow spherical structure and is filled with heat-conducting oil. The moisture in the raw material block of medicine is evaporated, making the hardened raw material block of medicine brittle, which is convenient for subsequent crushing; the lower end of the drying ball 7 is abutted with a scraper 15, and the scraper 15 is a cur...

Embodiment 2

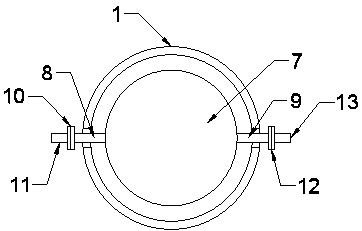

[0024] see figure 1 and figure 2 The difference between this embodiment and Embodiment 1 is that: the left side of the drying ball 7 is fixedly connected with a left shaft 8, the right side of the drying ball 7 is fixedly connected with a right shaft 9, and the left shaft 8 runs through the processing cylinder 1 and the bracket 2 , the left rotary shaft 8 is connected and driven by the first transmission belt 26 and the transmission shaft 24, thereby making the drying ball 7 rotate, so that the drying ball 7 is in a rotating state, avoiding too long contact time between the raw material and the drying ball surface, and at the same time, it is convenient for unloading The right-hand shaft 9 is connected with the driven shaft 28 through the second transmission belt 27, and the driven shaft 28 is connected to the pulverizing blade roller 5 through the second transmission gear set 29 to drive, and then drives the pulverizing blade roller 5 to rotate, and the raw material is initi...

Embodiment 3

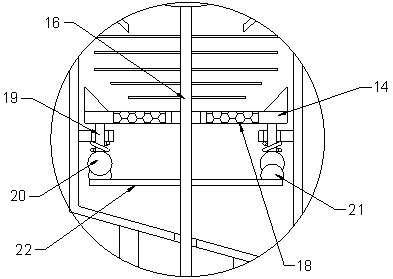

[0028] see figure 1 and image 3 The difference between this embodiment and Embodiment 2 is that: the lower end of the sieve plate 18 is fixedly connected with sleeve rods 19 distributed in a circle, the sleeve rods 19 are sleeved with a fixed plate, and the fixed plate is fixedly connected with the inner wall of the processing cylinder 1; The lower end of the sleeve rod 19 is fixedly connected to the extruding ball 20, the sleeve rod 19 is located above the extruding ball 20 and is provided with a spring, and the spring abuts against the lower end of the fixing plate; the extruding ball 20 abuts against an extruding block 21 , the extrusion block 21 is fixedly connected to the central shaft 16 through the connecting rod 22. When the central shaft 16 drives the connecting rod 22 and the extrusion block 21 to rotate, the extrusion block 21 squeezes the extrusion ball 20, so that the sieve plate 18 goes up and down Vibration, the sieve plate 18 is blocked to ensure continuous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com