Soil chlorinated hydrocarbon remediation method based on modified zero-valent iron

A restoration method and technology of zero-valent iron, applied in the field of soil restoration, can solve problems such as low restoration efficiency and poor contact, and achieve the effects of reducing the cost of chemicals, reducing consumption, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The soil chlorinated hydrocarbon remediation method based on modified zero-valent iron of the present embodiment comprises the following steps:

[0048] (1) Mill commercially available activated carbon fibers (particle size: 50 μm) and commercially available reduced zero-valent iron powder (particle size: 100 μm) in a high-energy ball mill (rotating speed: 5000 r / min, ball milling time: 5 h) to obtain activated carbon fibers Modified zero-valent iron, wherein the particle size of the activated carbon fiber modified zero-valent iron is 10 μm, and the content of the activated carbon fiber in the activated carbon fiber-modified zero-valent iron is 2wt%;

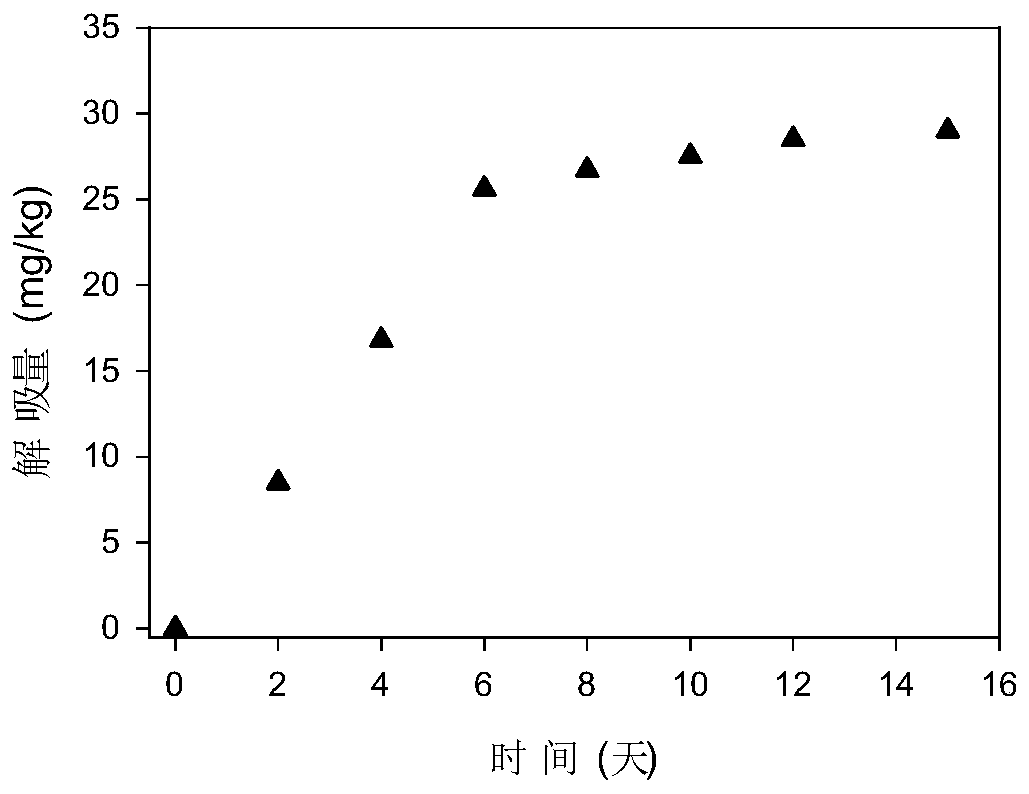

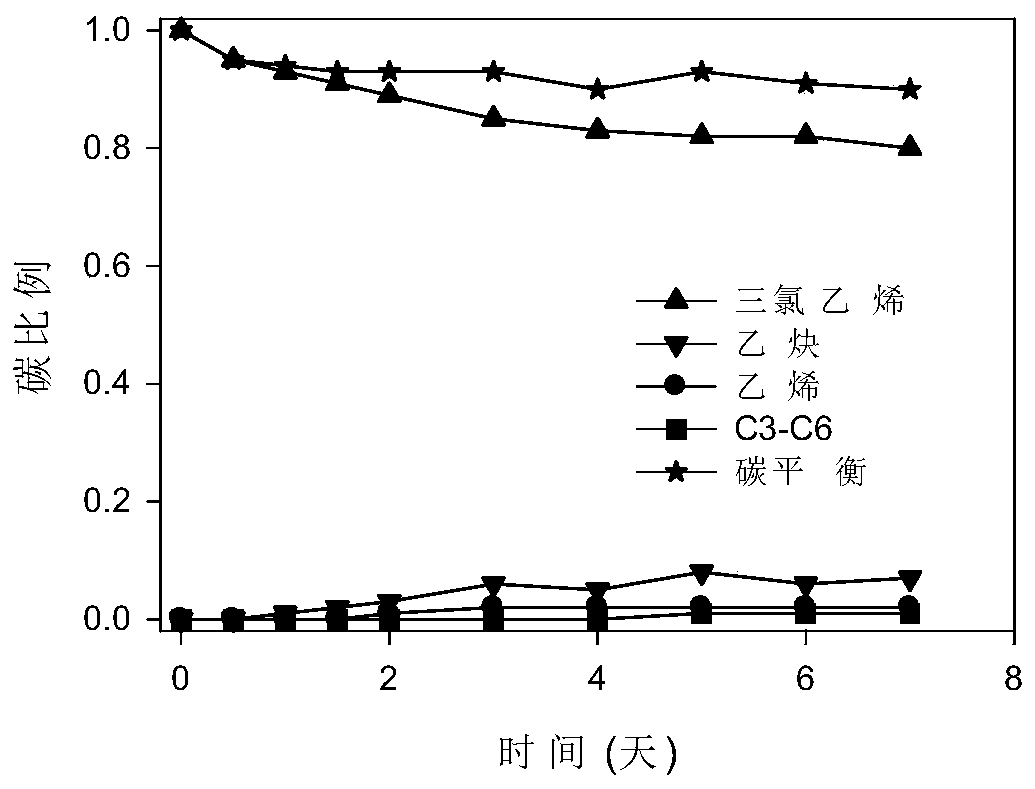

[0049] (2) 5g / kg activated carbon fiber modified zero-valent iron is added to the contaminated site soil mixed with a certain actual trichlorethylene (the concentration of trichlorethylene is about 95.8mg / kg) and then put into the box reactor, Then start the reaction after adding distilled water according to the mass rati...

Embodiment 2

[0051] The soil chlorinated hydrocarbon remediation method based on modified zero-valent iron of the present embodiment comprises the following steps:

[0052] (1) Mill commercially available activated carbon fibers (particle size: 50 μm) and commercially available reduced zero-valent iron powder (particle size: 100 μm) in a high-energy ball mill (rotating speed: 5000 r / min, ball milling time: 5 h) to obtain activated carbon fibers Modified zero-valent iron, wherein the particle size of the activated carbon fiber modified zero-valent iron is 10 μm, and the content of the activated carbon fiber in the activated carbon fiber-modified zero-valent iron is 5wt%;

[0053] (2) 5g / kg activated carbon fiber modified zero-valent iron is added to the contaminated site soil mixed with a certain actual trichlorethylene (the concentration of trichlorethylene is about 95.8mg / kg) and then put into the box reactor, Then start the reaction after adding distilled water according to the mass rati...

Embodiment 3

[0055] The soil chlorinated hydrocarbon remediation method based on modified zero-valent iron of the present embodiment comprises the following steps:

[0056] (1) Mill commercially available activated carbon fibers (particle size: 50 μm) and commercially available reduced zero-valent iron powder (particle size: 100 μm) in a high-energy ball mill (rotating speed: 5000 r / min, ball milling time: 5 h) to obtain activated carbon fibers Modified zero-valent iron, wherein the particle size of the activated carbon fiber modified zero-valent iron is 10 μm, and the content of the activated carbon fiber in the activated carbon fiber-modified zero-valent iron is 5wt%;

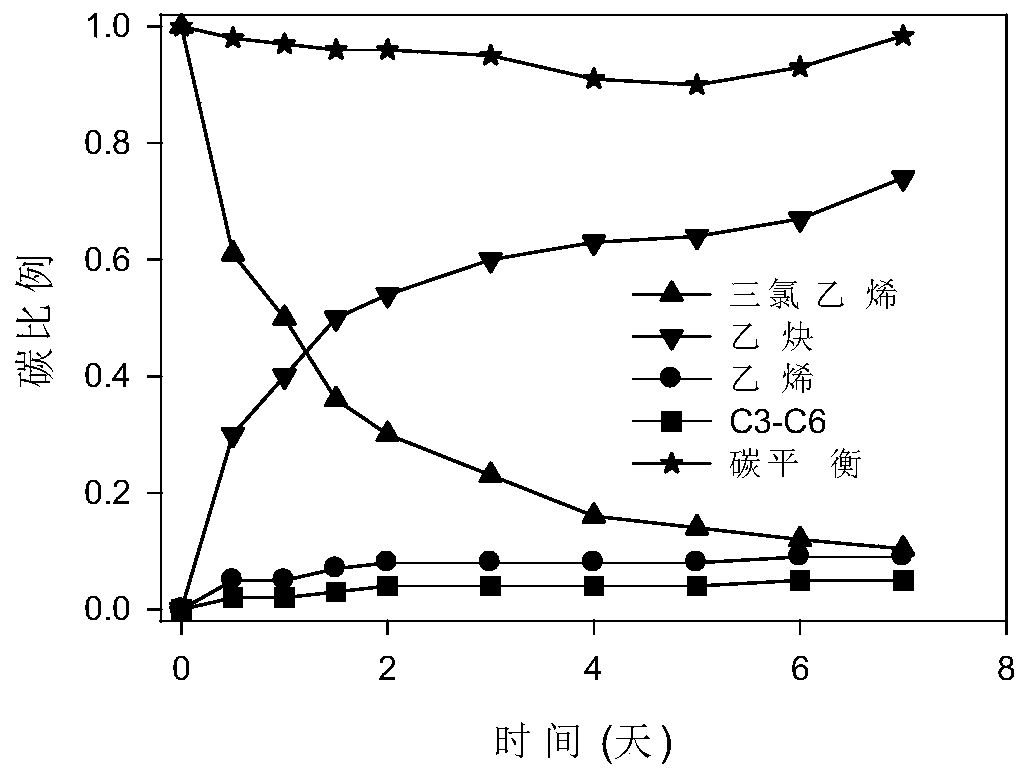

[0057] (2) 10g / kg activated carbon fiber modified zero-valent iron is added to the contaminated site soil mixed with a certain actual trichlorethylene (the concentration of trichlorethylene is about 95.8mg / kg) and then put into the box reactor, Then start the reaction after adding distilled water according to the mass rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com