A kind of manufacturing method of high radioactive waste vitrified body storage tank

A glass-curing, highly radioactive technology, used in manufacturing tools, hollow objects, forming tools, etc., to ensure tightening torque, prevent screw loosening, and reduce maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for manufacturing a vitrified body storage tank for high-level radioactive waste, comprising the steps of:

[0045] S1. Place the plate used to manufacture the storage tank on the die assembly of the bottom drawing die, then start the driving cylinder of the punch assembly of the bottom draw die, press down the punch assembly, and press the plate The middle part is drawn deep into the forming cavity of the die assembly to form a preliminary finished tank body with a tank bottom;

[0046] S2. The finished product of the preliminary tank body is removed from the die assembly of the bottom drawing die, and placed on the die assembly of the first drawing die, and then the driving of the punch assembly of the first drawing die is started Cylinder, press down the punch assembly, and continue to draw the side wall of the tank body formed by the middle part of the plate, so as to form a primary tank body product with a certain depth;

[0047] S3, take off the primary ...

Embodiment 2

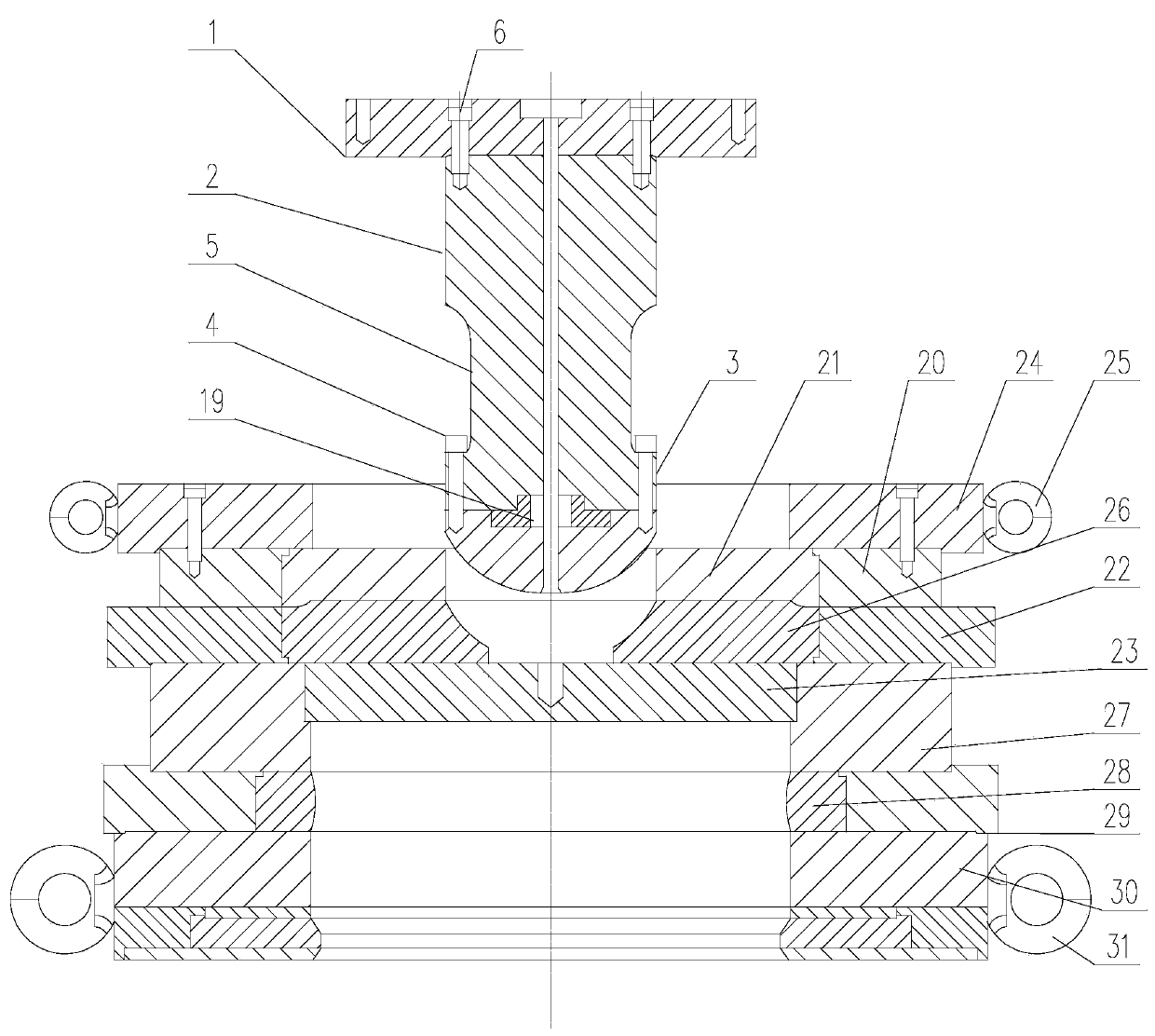

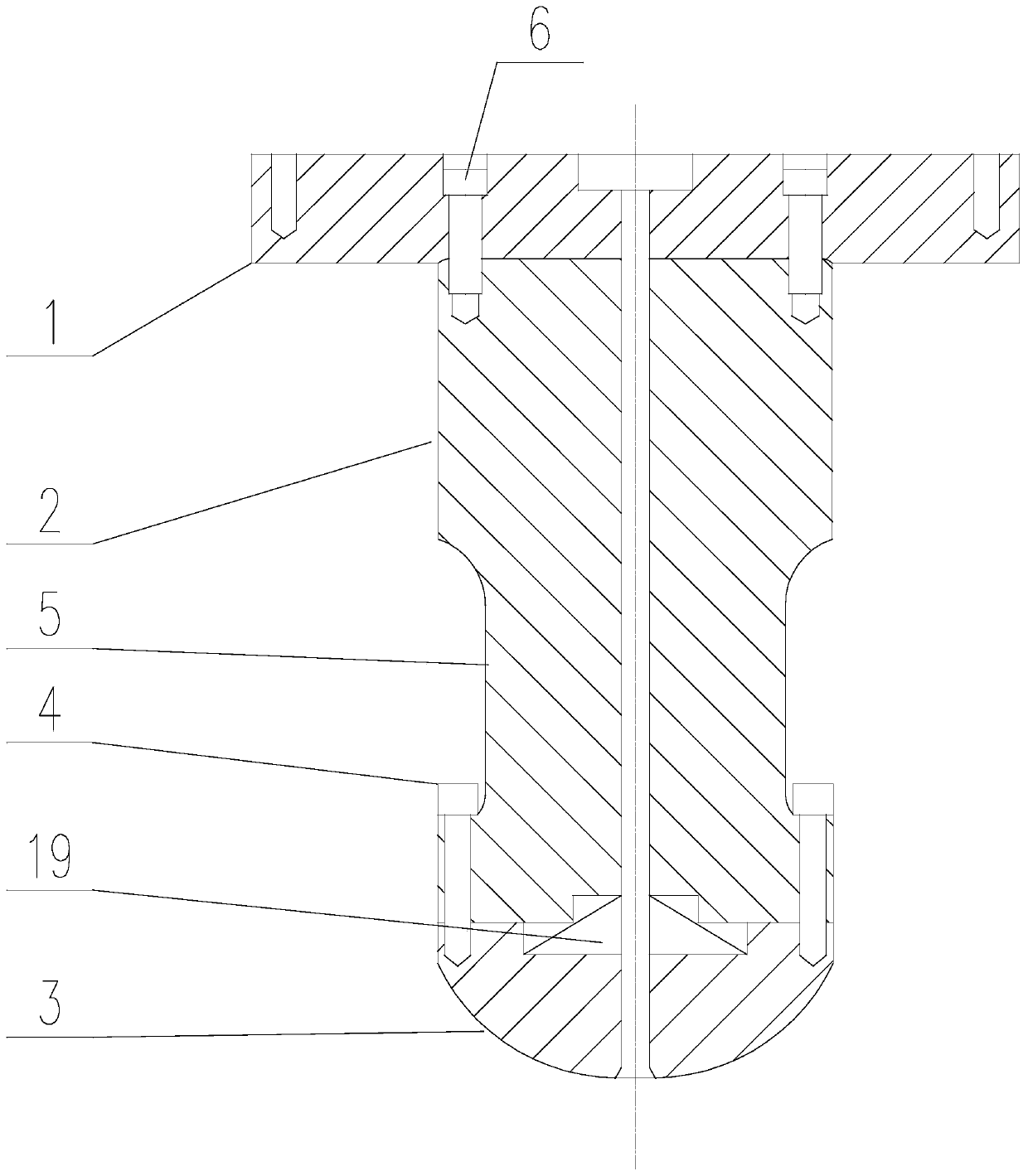

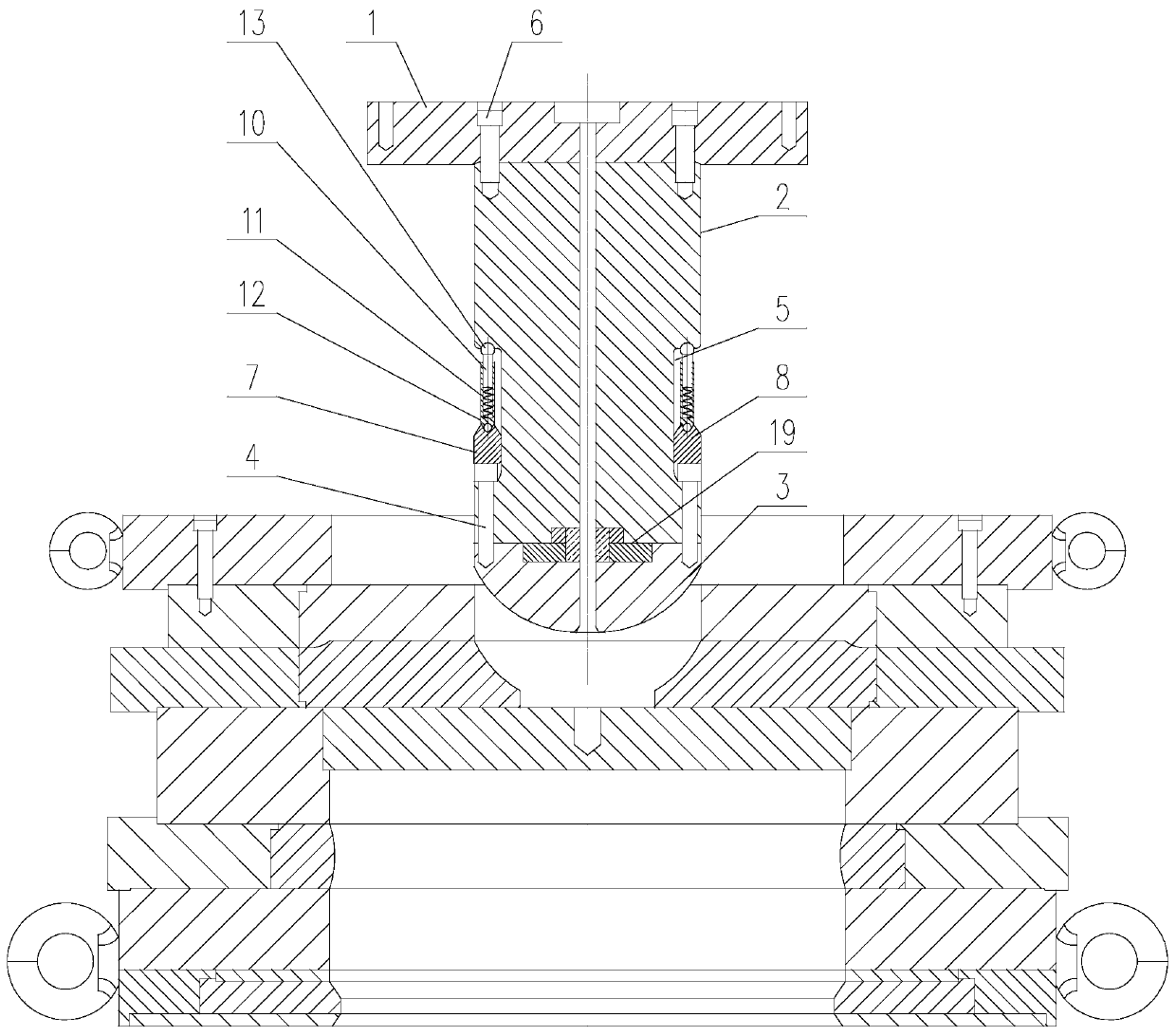

[0052] Such as Figure 2-Figure 4 As shown, the present invention is a kind of manufacturing equipment for the storage container of vitrified body, which includes a deep drawing die, and the deep drawing die includes a male mold assembly and a female mold assembly located below the male mold assembly, and the male mold The assembly includes a coaxial extension die 2 and a punch 3 connected by a screw A4, and an annular groove A5 coaxial with the extension die 2 is provided on the side wall of the extension die 2, and the ends of the rods of the screws A4 pass through in turn. After passing through the lower side groove wall of the annular groove A5 and the extension die 2, it is threadedly connected with the punch 3, and the end of the extension die 2 far away from the punch 3 is connected with the punch base 1 through a screw B6, and is set on the extension die 2. A tightening assembly is provided, and the tightening assembly includes a ring 7, an elastic telescopic rod and a...

Embodiment 3

[0061] This embodiment is an implementation description of the first specific implementation structure of the telescopic rod.

[0062] Such as Figure 2-Figure 3 As shown, in the present invention, the telescopic rod includes a moving rod 10, a spring 11 and a mounting cylinder 12 connected in sequence, the top end of the moving rod 10 is in contact with the upper groove wall of the annular groove A5, and the bottom end is inserted into the mounting cylinder 12, and contact with the bottom of the installation cylinder 12 through the spring 11, and the spring 11 is in a compressed state, the bottom of the installation cylinder 12 is connected with the upper surface of the ring 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com