Feeding machine and pipe cutting production line adopting feeding machine

A technology for feeding machines and production lines, applied in the direction of pipe shearing devices, shearing devices, and attachments to shearing machines, etc., which can solve the problems of easy deformation of pipes and difficult separation of pipes, and achieve wide application range, simple structure, and large size. The effect of cutting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

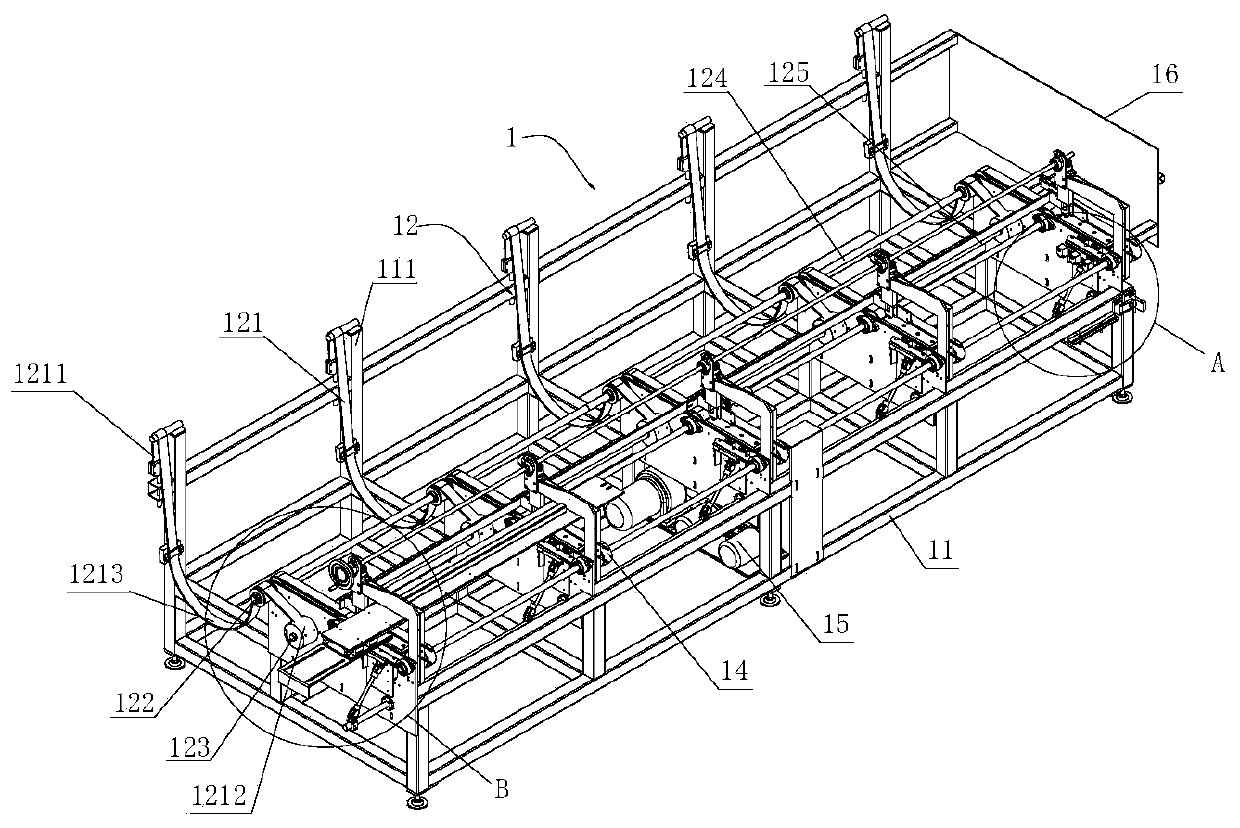

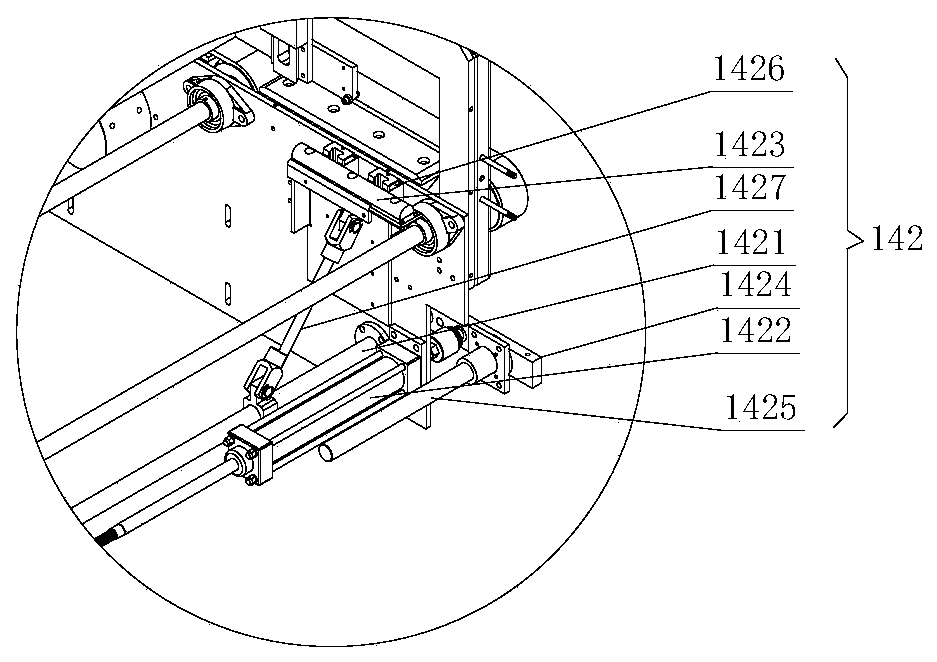

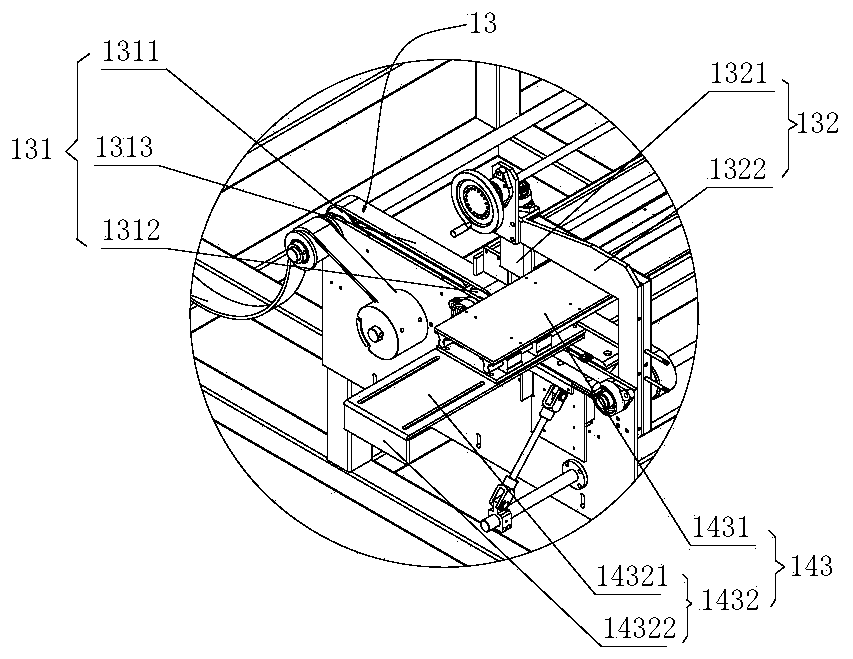

[0112] Such as Figure 1 to Figure 16 As shown, a pipe cutting production line is provided in this embodiment, which includes a feeder 1, a pipe cutter 2 and a feeder;

[0113] The feeding machine includes a feeding mechanism, a coding mechanism and a feeding mechanism. The feeding mechanism transports the pipes to the coding mechanism. The coding mechanism is used to break up the received pipes and send the broken pipes to the feeding mechanism . Breaking up here means to divide the piles of pipes one by one, and each pipe is arranged in the same direction, or to divide the pipes into groups, and each group has the same number of pipes and the same arrangement direction.

[0114] During the conveying process of the pipes on the coding mechanism, the scattere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com