Automatic production line based on intelligent assembly mechanism

An automated production line and assembly mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving the scope of application, facilitating adjustment, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

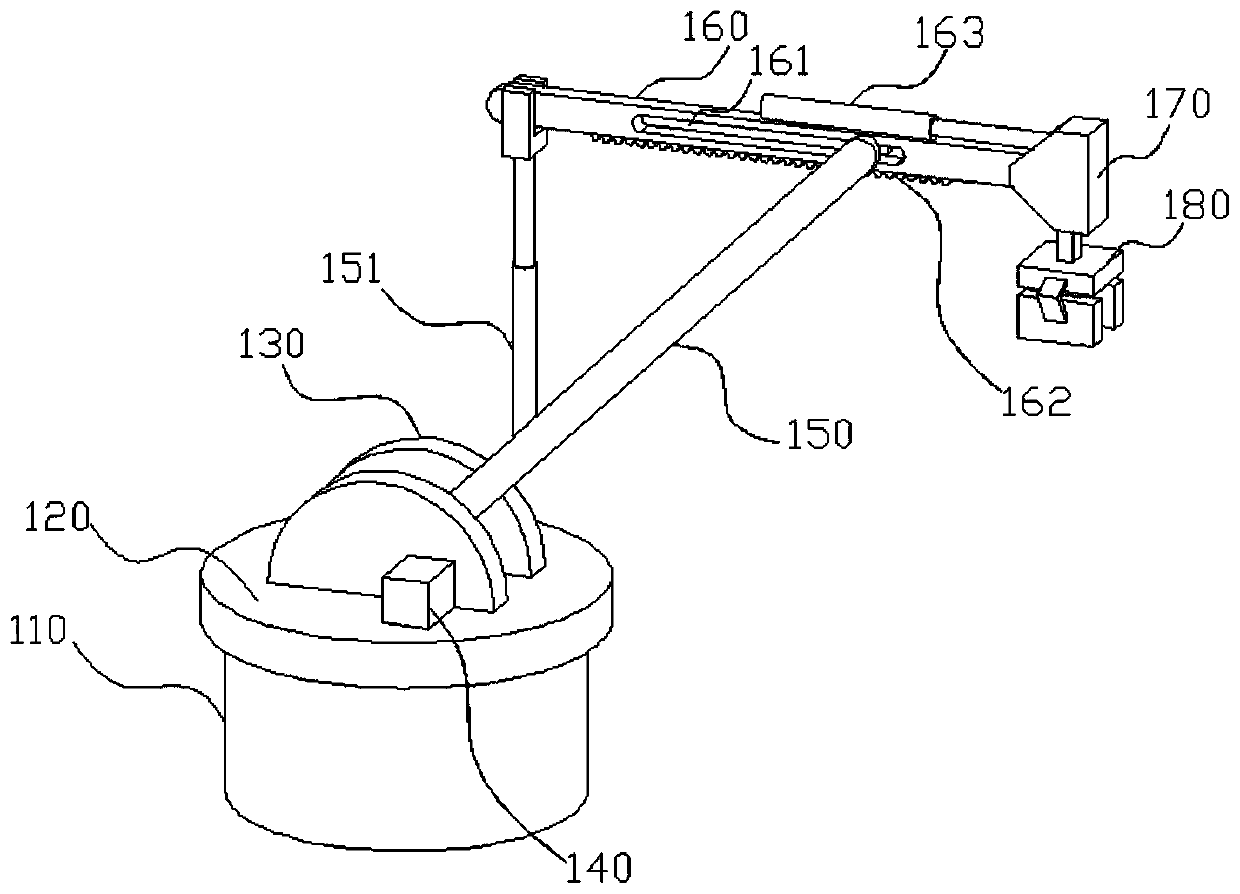

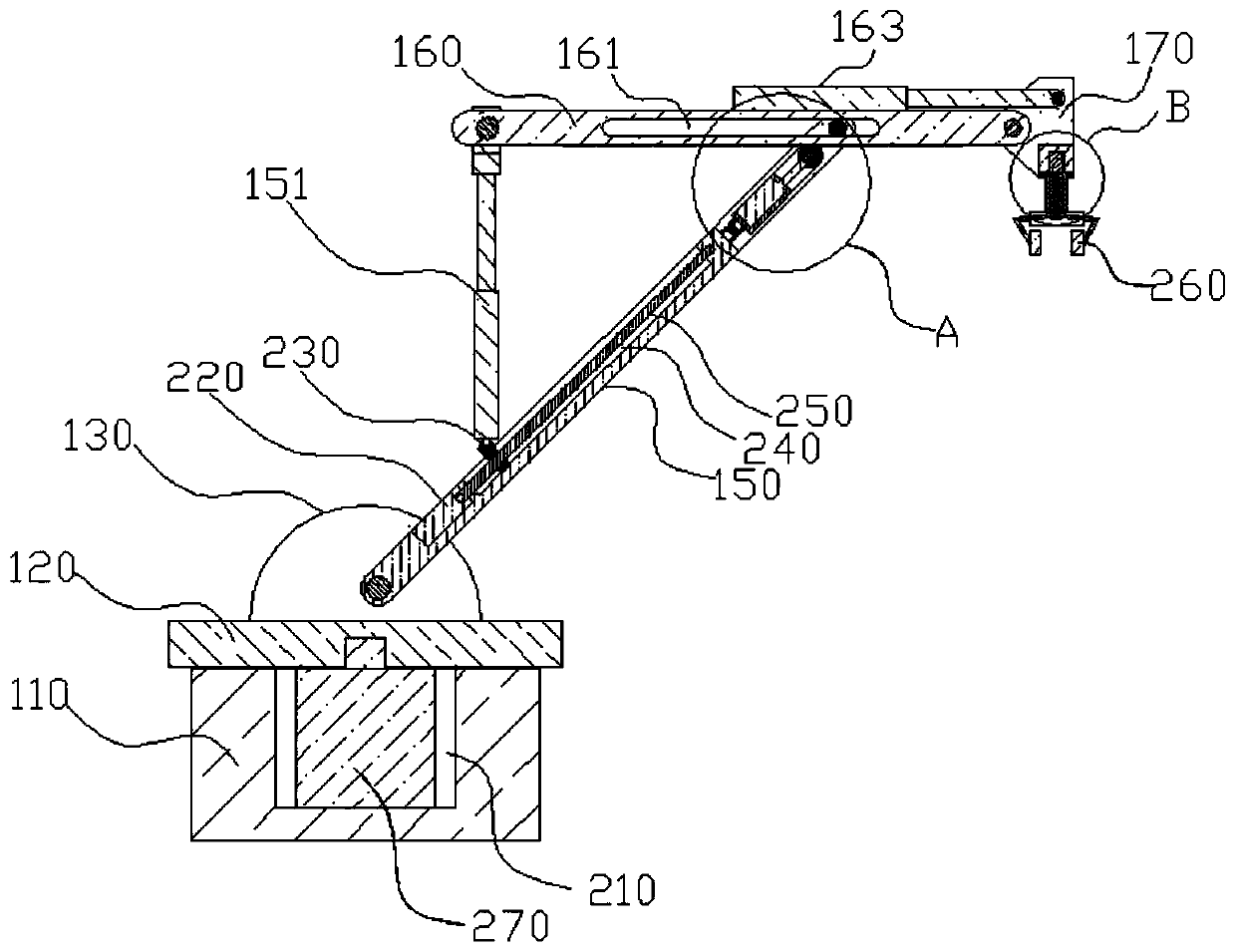

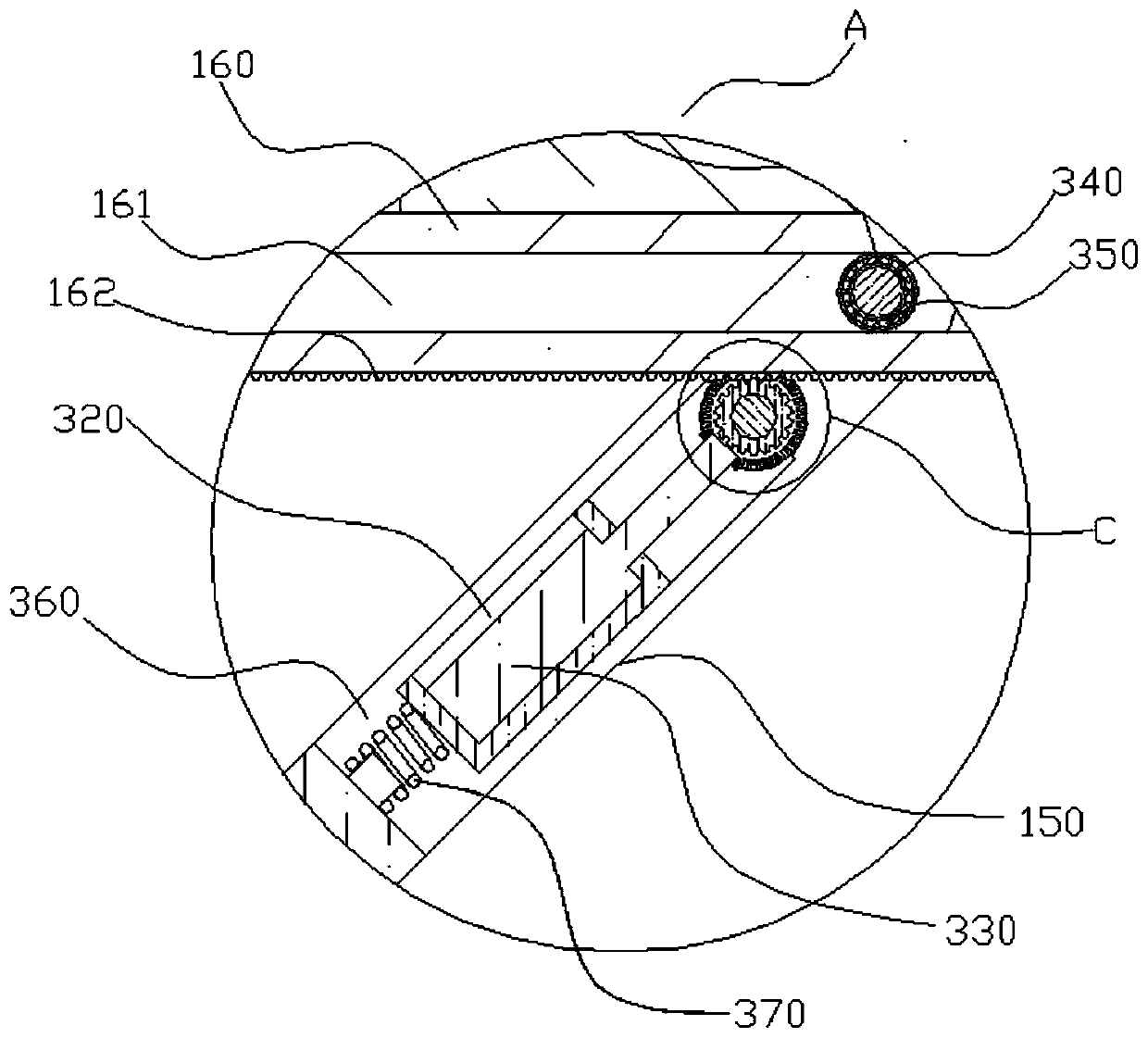

[0061] Such as Figure 1-29 As shown, the present embodiment provides an automated production line based on an intelligent assembly mechanism, which includes automated production equipment, the automated production equipment includes a handling mechanism, and the handling mechanism includes a support platform 110, and the support platform 110 is provided with a groove with an upward opening. 210, the groove 210 is provided with a first motor 270, the upper surface of the support table 110 is provided with a circular first support plate 120, the center of the first support plate 120 is connected with the rotating shaft of the first motor 270, the second A support plate 120 is provided with two relatively vertically arranged second support plates 130, a first support rod 150 is hinged between the two second support plates 130, and two opposite ends of the first support rod 150 are provided. The first installation shaft 610 that is arranged and perpendicular to the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com