Quick-changing multi-spindle tool

A multi-shaft device and output shaft technology, applied in the field of multi-shaft devices, can solve the problems of laborious, time-consuming and disadvantageous multi-shaft device maintenance, etc., and achieve the effects of improving installation and replacement efficiency, labor-saving disassembly and replacement, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

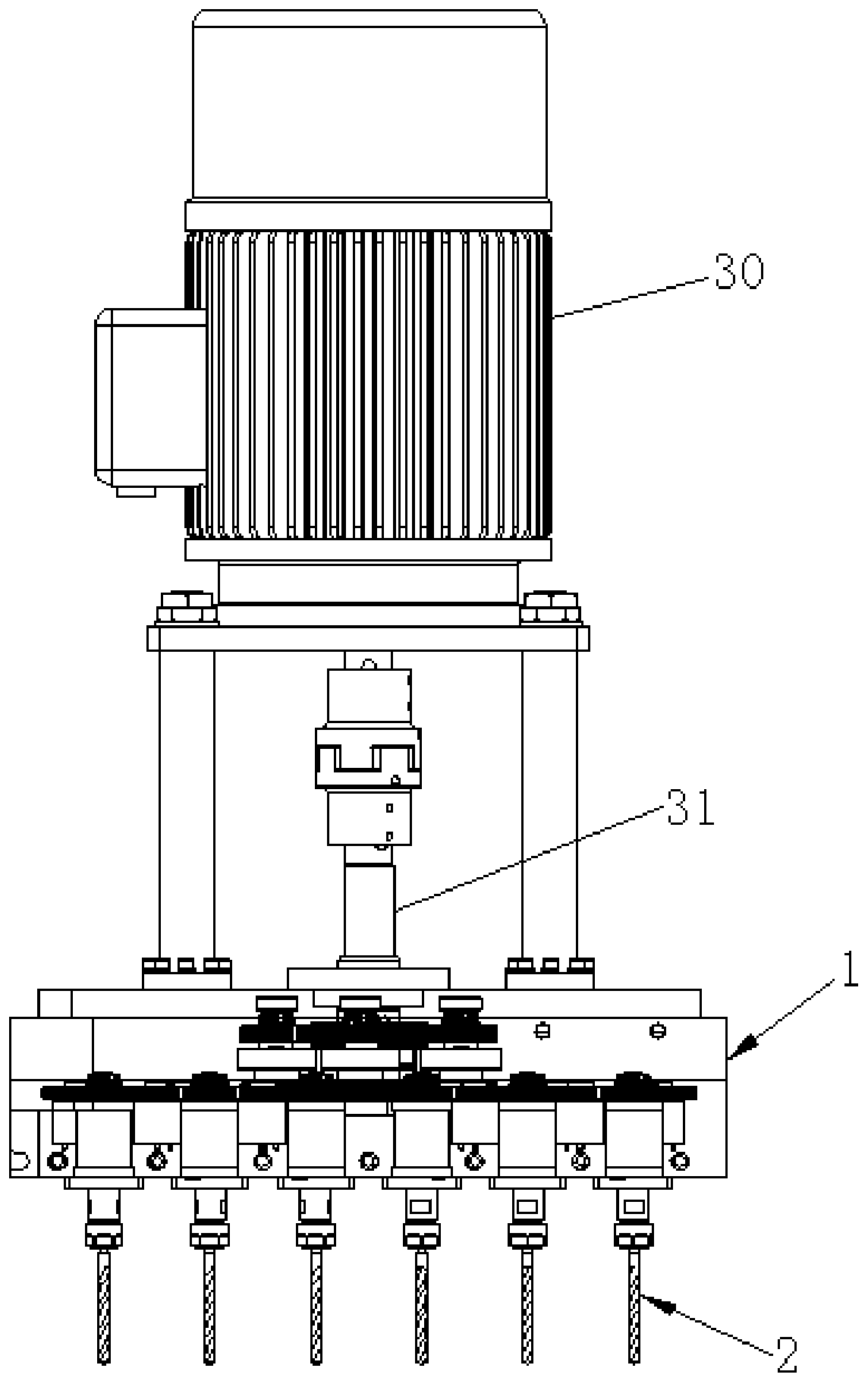

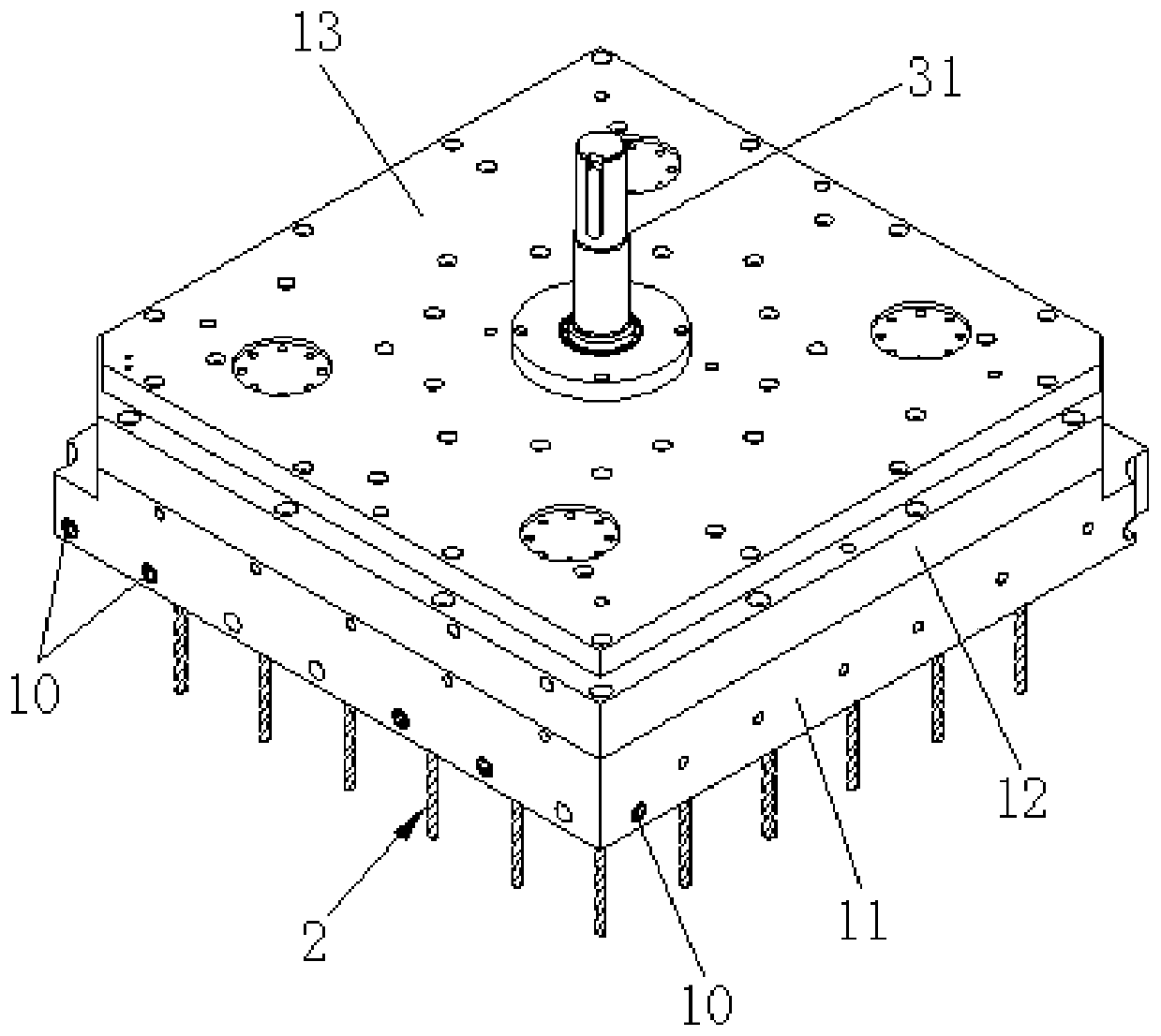

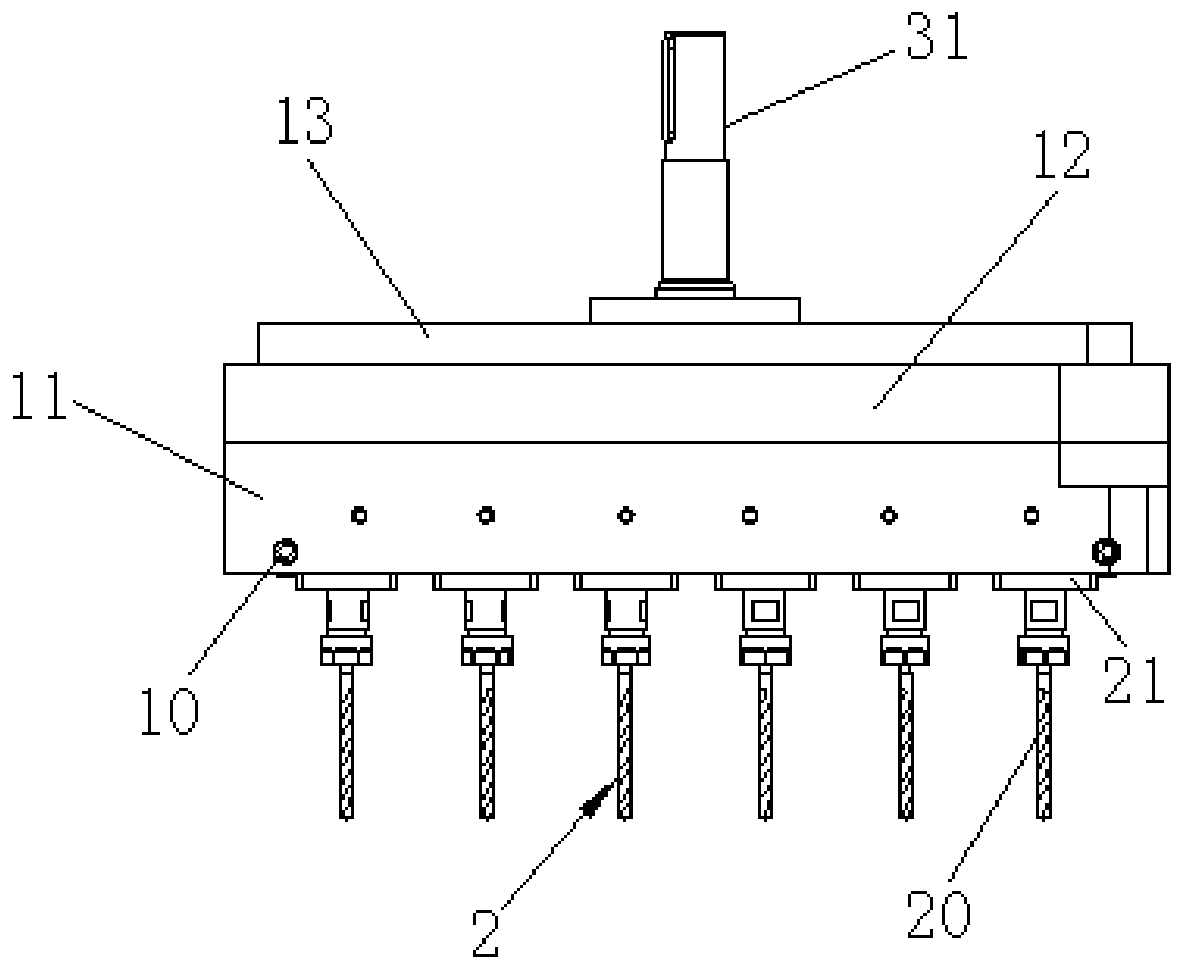

[0037] Please refer to the attached figure 1 to attach Figure 5 As shown, they are respectively the structural diagram of the quick-change multi-axis device of the present invention, the partial three-dimensional structure diagram and the cross-sectional structure diagram of the quick-change multi-axis device after the motor is removed, and the quick-change multi-axis device after the motor and the motor are removed. Schematic diagram of the partial three-dimensional structure behind the board seat and under two different viewing angles.

[0038] The quick-change multi-axis device includes a mounting base 1, several output shafts 2 and a power unit, wherein the several output shafts 2 are respectively detachably mounted on the mounting base 1, and the power unit is also It is installed on the mounting base 1, and the power unit can also drive several output shafts 2 to rotate; in addition, a cooling channel 10 for cooling liquid flow is arranged on the mounting base 1 to rea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap