Production equipment capable of separating regenerative polyester bottle chips through specific gravity method

A technology for recycled polyester and production equipment, which is applied in the field of production equipment for separating recycled polyester bottle flakes by the specific gravity method, can solve the problems of high separation cost, incomplete separation, and poor separation effect, and achieve low separation cost, complete separation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

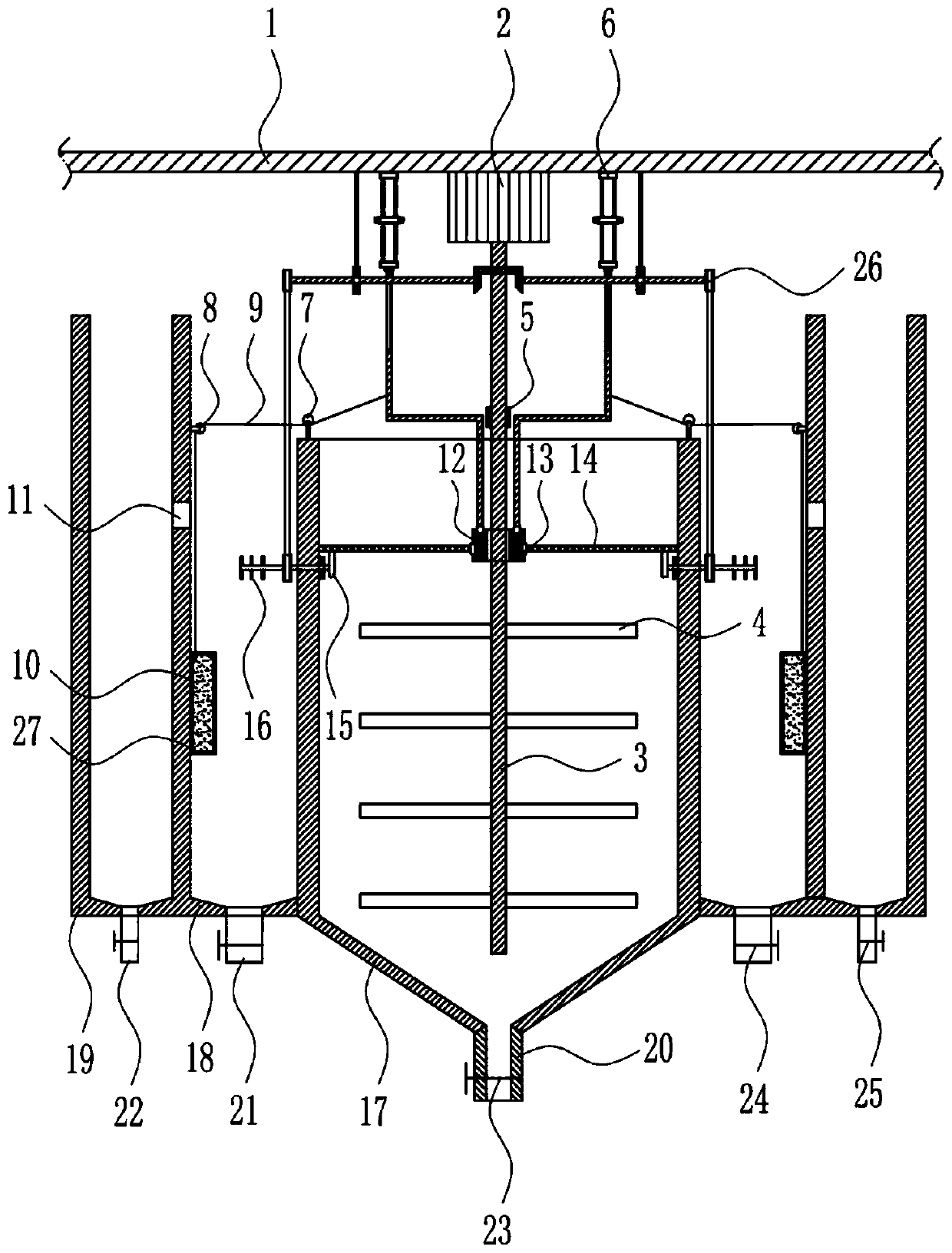

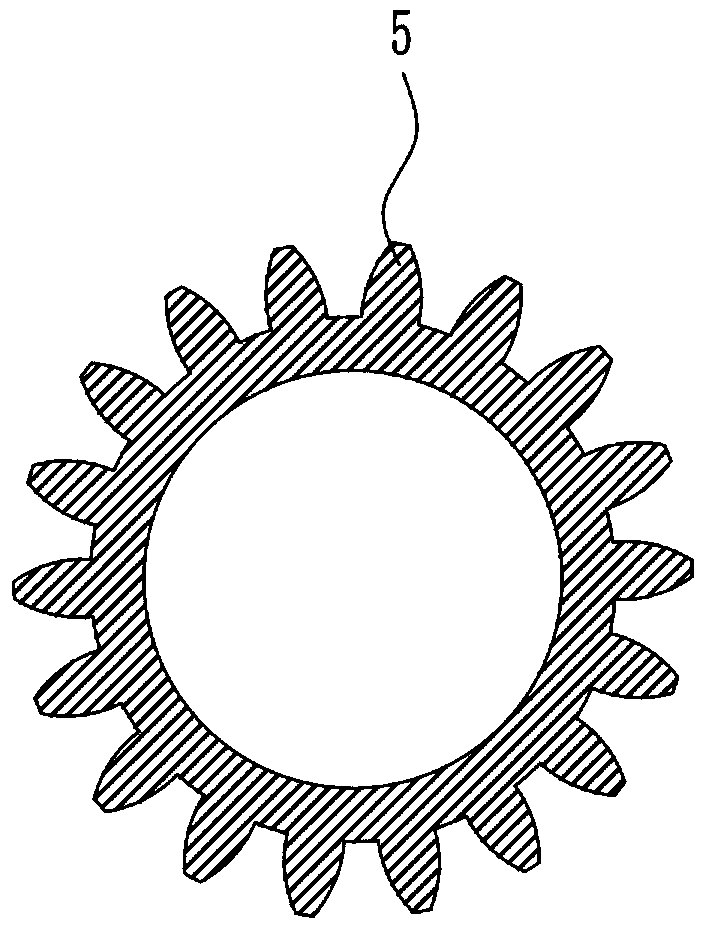

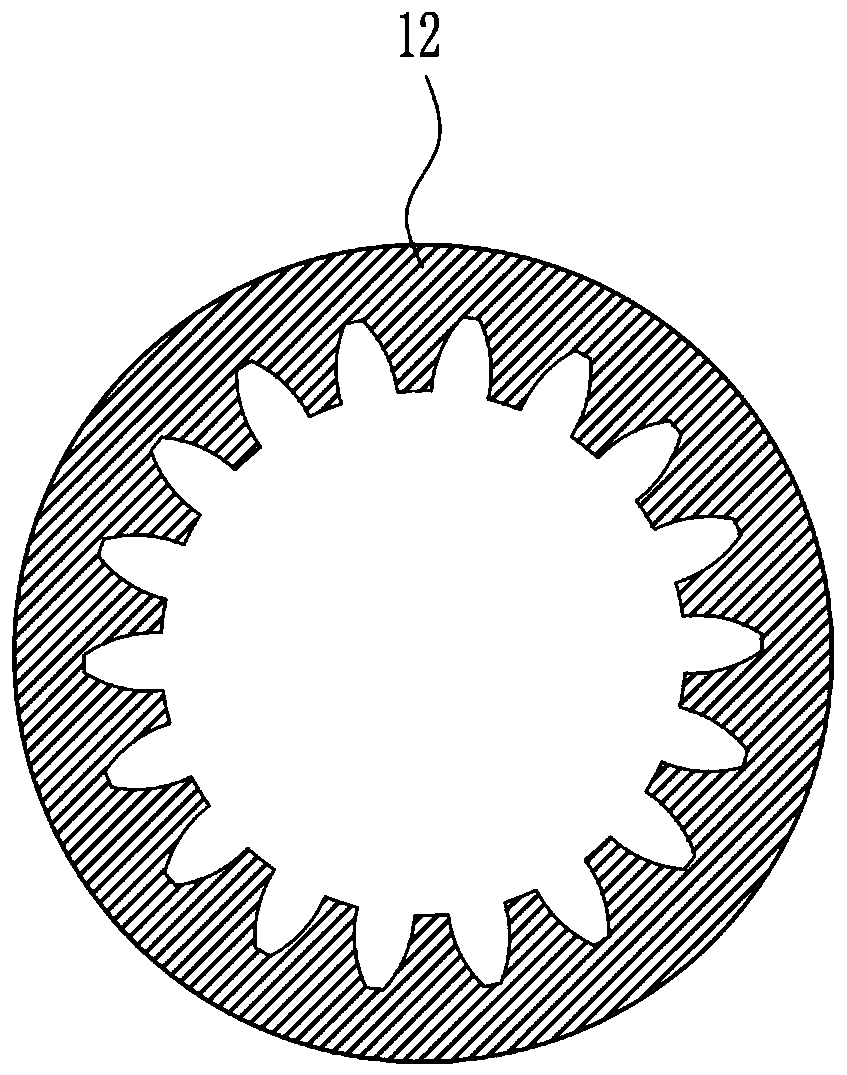

[0029] A production equipment for separating recycled polyester bottle flakes by specific gravity method, such as Figure 1-7 As shown, it includes a frame 1, a motor 2, a first rotating shaft 3, a first stirring rod 4, a first gear 5, a lifting mechanism 6, a first guide wheel 7, a second guide wheel 8, a pull cord 9, and a weight 10. Sliding sleeve 12, ring slider 13, mesh plate 14, cam 15, second stirring rod 16, stirring tank 17, separation box 18, collection box 19, hopper 20, first discharge pipe 21, second discharge The material pipe 22, the first valve 23, the second valve 24, the third valve 25 and the drive mechanism 26; the drive mechanism 26 is fixedly connected to the two side walls of the mixing tank 17, and a cam is fixedly connected to an output end of the drive mechanism 26. 15. The cam 15 is located in the stirring tank 17, and the other output end of the driving mechanism 26 is fixedly connected with a plurality of second stirring rods 16; the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com