Control method of drive system, drive system and new energy vehicle

A new energy vehicle and drive system technology, applied in the automotive field, to avoid cost burden and cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

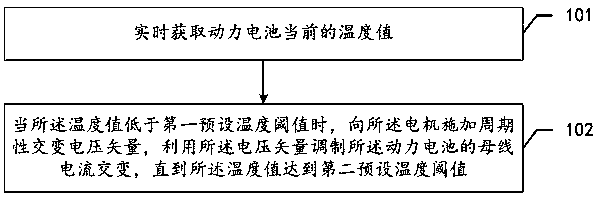

[0080] see figure 1 , which is a flow chart of a method for controlling a drive system provided in an embodiment of the present application.

[0081] Such as figure 1 As shown, the control method of the driving system provided in this embodiment includes:

[0082] Step 101: Obtain the current temperature value of the power battery in real time.

[0083] First, the application scenario of the method is described. The control method provided in this embodiment is applied to a motor controller of a drive system of a new energy vehicle. In addition to the motor controller, the drive system also contains other components, such as power batteries, motors, etc. The power battery contains multiple battery cells. The motor may be a three-phase motor. Of course, the drive system may also include other components, and the types and quantities of the components included in the drive system are not limited here.

[0084] It is understandable that the temperature of the power battery...

no. 2 example

[0103] see image 3 , which is a flowchart of another driving system control method provided in the embodiment of the present application.

[0104] Such as image 3 As shown, the control method of the driving system provided in this embodiment includes:

[0105] Step 301: Obtain the current temperature value of the power battery in real time.

[0106] In this embodiment, the implementation manner and purpose of step 301 are the same as those of step 101 in the foregoing embodiments, and the relevant description of step 301 may refer to the foregoing embodiments, and will not be repeated here.

[0107] Step 302: When the temperature value is lower than a first preset temperature threshold, apply a periodic alternating voltage vector to the motor, and use the voltage vector to modulate the alternating current of the busbar of the power battery.

[0108] It should be noted that, in practical applications, the voltage vector applied for the first time is a preset voltage vector...

no. 3 example

[0140] see Image 6 , which is a schematic structural diagram of a driving system provided in an embodiment of the present application.

[0141] Such as Image 6 As shown, the drive system provided by this embodiment includes:

[0142] Power battery 601, first temperature sensor 602, motor 603 and motor controller 604;

[0143] Wherein, the first temperature sensor 602 is used to detect the current temperature value of the power battery 601 in real time, and transmit the temperature value to the motor controller 604 in real time;

[0144] The motor controller 604 is configured to apply a periodic alternating voltage vector to the motor 603 when the temperature value is lower than a first preset temperature threshold, and use the voltage vector to modulate the bus current of the power battery 601 alternating until said temperature value reaches said first preset temperature threshold;

[0145] When the voltage vector is positive, the power battery 601 releases electric ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com