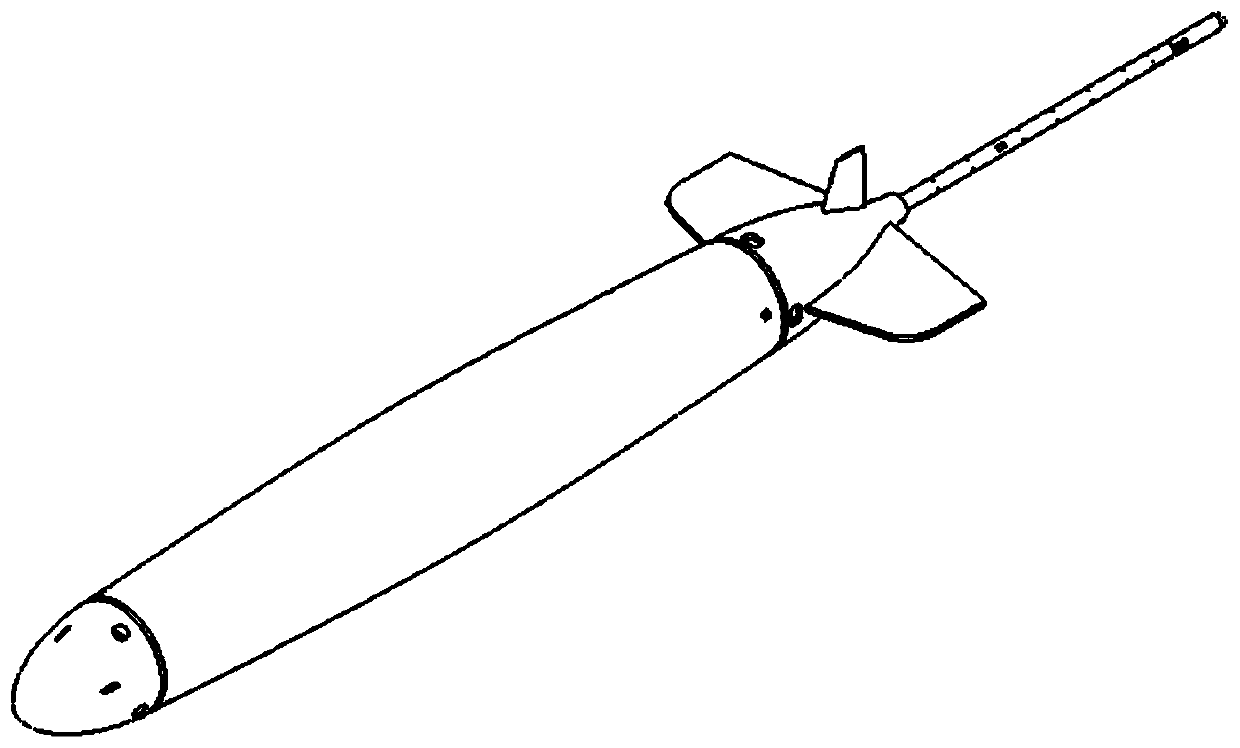

Rheid liquid-filled underwater glider with nearly neutral buoyancy

A near-neutral, glider technology, used in underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of increased buoyancy, decreased buoyancy, and inability to accurately control the stroke of the glider, reducing energy consumption and reducing energy consumption. Adjusting the demand for fuel volume, improving the effect of endurance and cruising history

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

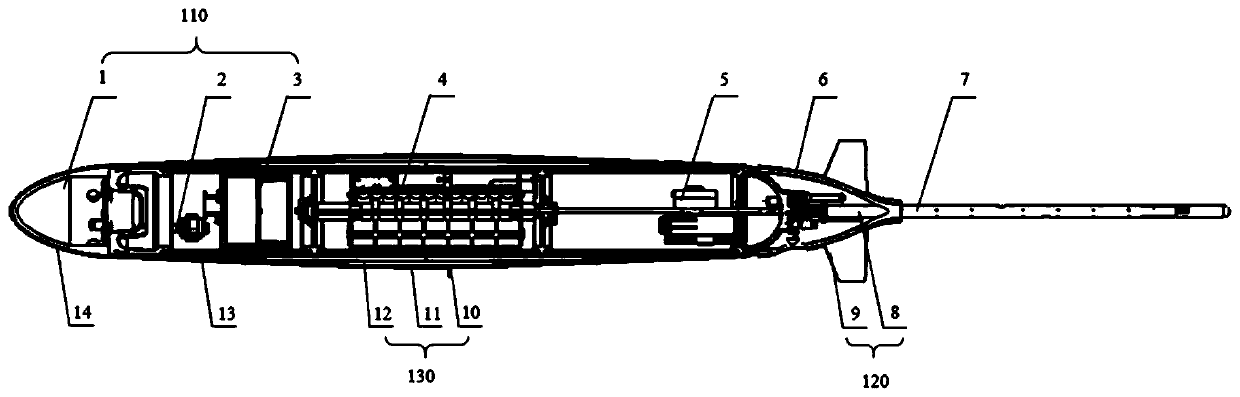

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0017] Such as figure 1 As shown, the soft liquid-filled underwater glider of the present invention mainly includes a soft liquid-filled cabin 130, a pressure-resistant cabin 13, a front shroud 14, a rear shroud 6, a wing unit 120, a buoyancy adjustment unit 110, and an attitude adjustment unit. 4. The main control unit 5 and the antenna unit 7; wherein the flexible skin 11 of the soft liquid-filled chamber 130 is assembled and sealed with the pressure-resistant chamber 13, and the two are completely bonded when they are not filled with liquid. Fill the cabin with a compressible liquid 12 through the self-sealing nozzle 10. In this embodiment, the compressible liquid 12 is mineral oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com