Denitrification system for synchronously achieving nitrification and denitrification and application method thereof

A technology of denitrification and anaerobic denitrification, applied in the field of denitrification system that simultaneously realizes nitrification and denitrification, can solve the problems that affect the rate and quality of denitrification, and it is difficult to realize, so as to achieve a good growth and enrichment environment and avoid sediment pollution Slime, the effect of high efficiency in retaining microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

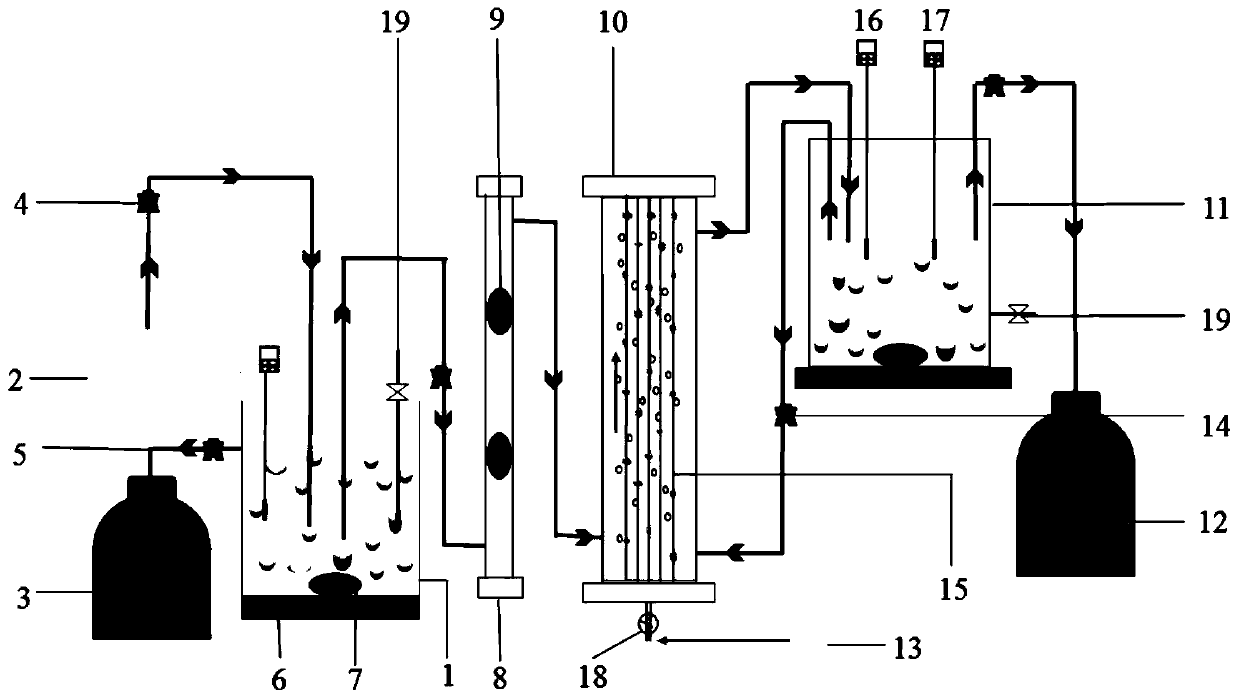

[0043] Such as figure 1 As shown, this embodiment provides a denitrification system that simultaneously realizes nitrification and denitrification, including an aerobic nitrification reaction device, a filter device and an anaerobic denitrification device;

[0044] The aerobic nitrification reaction device includes an open double-layer glass bottle reactor 1, a feeding tank 2 and a first water outlet bottle 3. The inner layer of the open double-layer glass bottle reactor 1 is used for enrichment growth and nitrification of aerobic nitrification bacteria In the reaction place, the interlayer of the open double-layer glass bottle reactor 1 is connected with constant temperature water to ensure the constant temperature reaction. A nitrification reaction inlet pump 4 is arranged between the feeding tank 2 and the double-layer glass bottle reactor 1. A water pump 5 for nitrification reaction is provided between the water bottle 3 and the double-layer glass bottle reactor 1 .

[00...

Embodiment 2

[0054] This embodiment provides an application method of a denitrification system that simultaneously realizes nitrification and denitrification, a high-efficiency system that can simultaneously realize nitrification and denitrification anaerobic methane oxidation and anammox, and can completely remove ammonium nitrogen in water. A sustainable approach to denitrification, including the following steps:

[0055] (1) Inoculation of the reactor: Put the aerobic biological filler into the open double-layer glass bottle reactor, let it grow and enrich the nitrifying bacteria by itself, and the domesticated denitrifying anaerobic methane oxidizing archaea, denitrifying anaerobic bacteria The flocculent sludge of oxymethane oxidizing bacteria (also known as DAMO functional microorganisms) and anaerobic ammonium oxidation (Anammox functional microorganisms) functional microorganisms is inoculated into the hollow fiber membrane bioreactor, wherein the nitrogen in the feeding tank connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap