Asphalt concrete seamless retractor device and construction method thereof

An asphalt concrete, seamless expansion and contraction technology, used in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems affecting the bridge structure itself, the discomfort of bridge passers, and achieve good engineering application value, smooth driving and comfort. Good, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

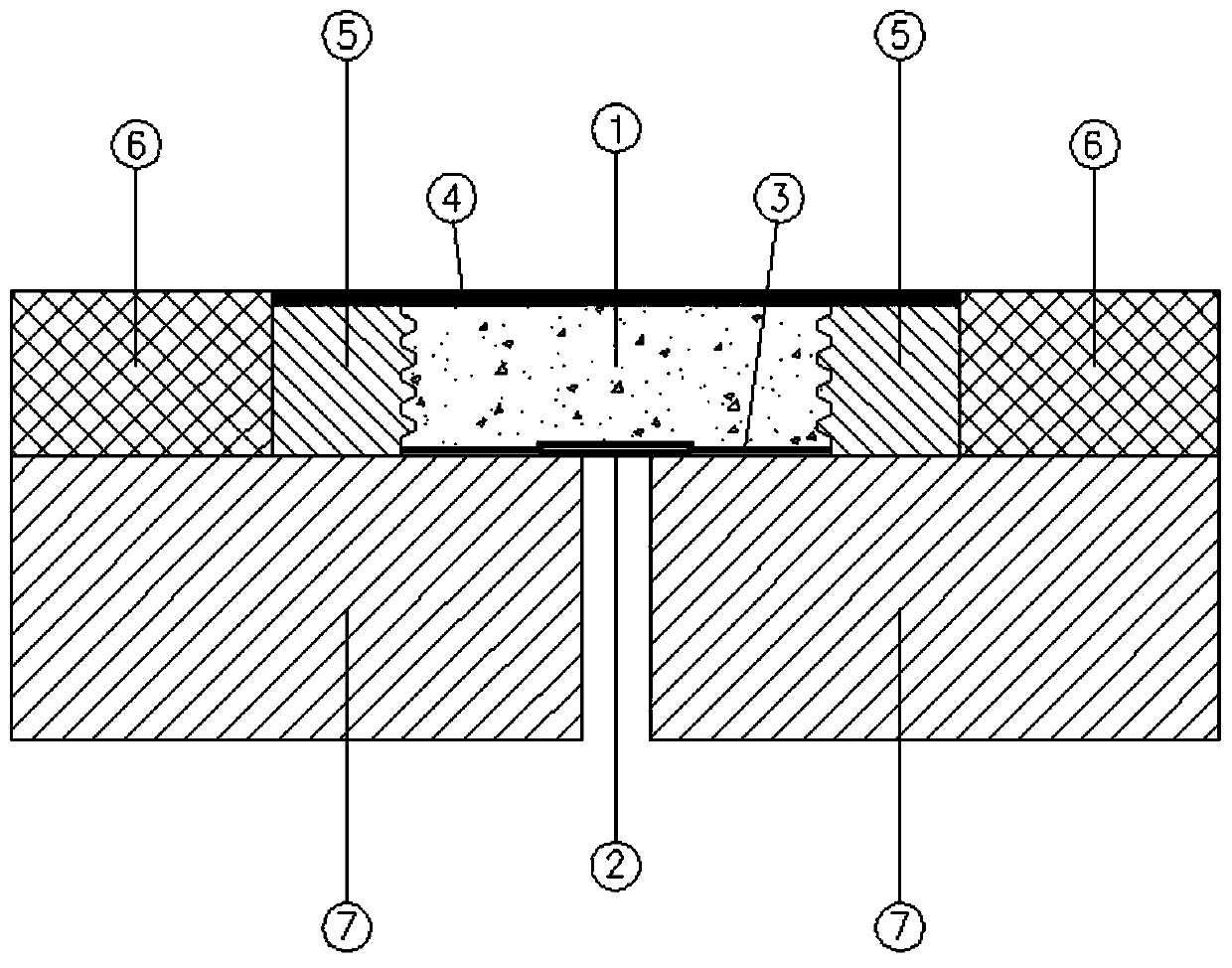

[0025] refer to figure 1 , an asphalt concrete seamless expansion device of the present invention, comprising an asphalt concrete pouring layer 1, a seam span 2, an isolation layer 3 and a pavement transition zone 5, and the seam span 2 is laid between two bridge ends 7 or Above the expansion joint formed between the back wall of the abutment and the end of the bridge, the length of the seam span plate 2 exceeds the width of the expansion joint by not less than 4cm, and the pavement transition belt 5 is arranged on the bridge deck pavement layer to expand and contract in 6 directions. The side where the seam extends, the isolation layer 3 is laid on the bottom surface of the post-cast slot formed between the two pavement transition belts 5, the isolation layer 3 is arranged on the top surface of the seam-spanning plate 2, and the asphalt The concrete pouring layer 1 is arranged in the post-casting slot above the isolation layer 3, and the surface of the pavement transition zon...

Embodiment 2

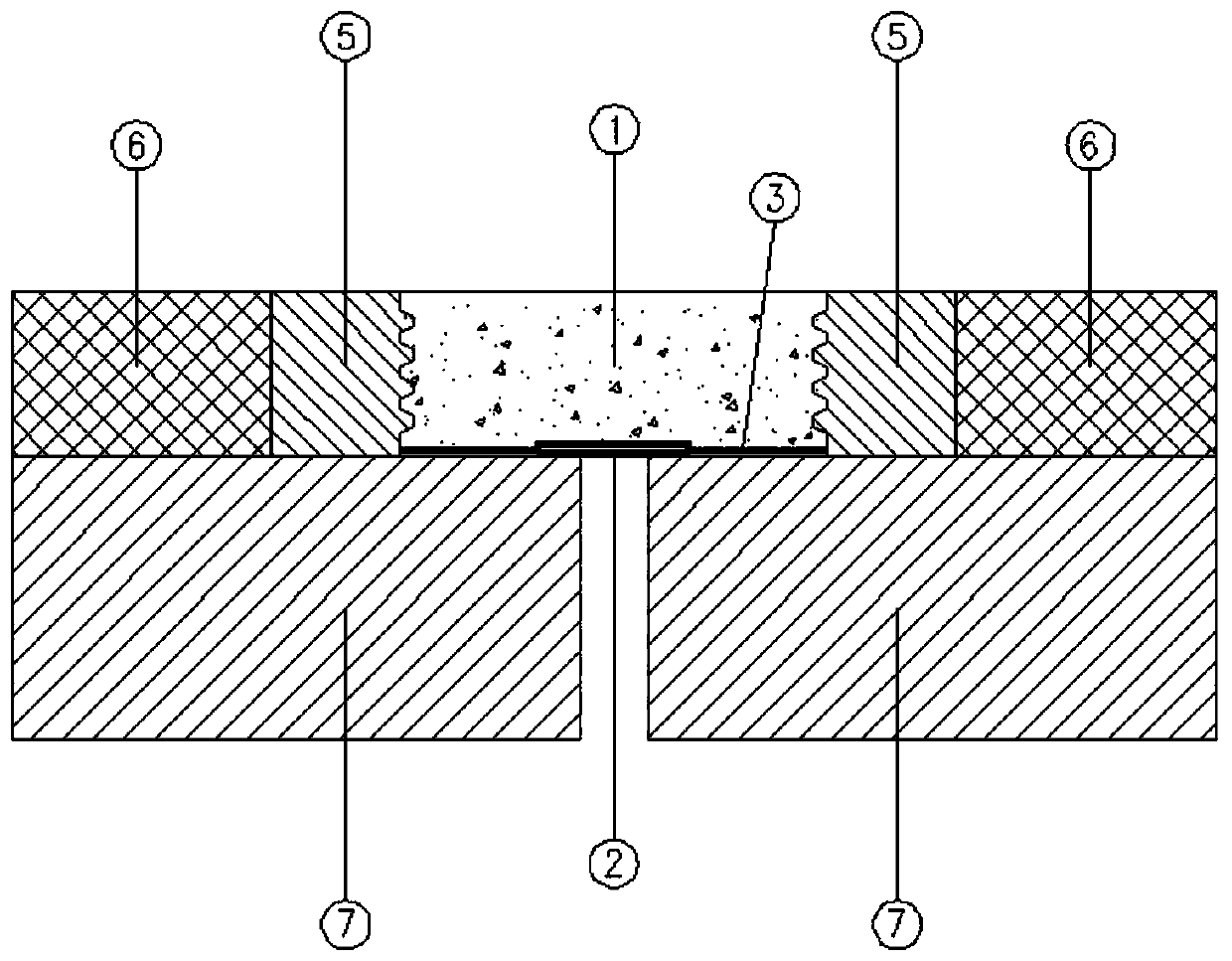

[0028] refer to figure 2 The difference from Example 1 is that there is no asphalt layer 4, and the top surface of the pavement transition zone 5 and the asphalt concrete pouring layer 1 is flush with the top surface of the bridge deck pavement layer 6.

[0029] refer to figure 1 , a construction method of an asphalt concrete seamless expansion device, comprising the steps of:

[0030] Step 1. Pouring construction of the pavement transition zone 5: when the bridge deck pavement layer 6 is asphalt concrete, it is necessary to design a separate reinforcement design or section steel reinforcement design for the pavement transition zone 5, and to correct the corrugated surface on the side of the asphalt concrete Customized individual formwork is formed, and then the pavement transition zone 5 is cast in place, and the bridge deck asphalt concrete can be poured after the pavement transition zone 5 reaches the required strength; when the bridge deck pavement layer 6 is cement conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com