An internal drainage method and construction method of an open-pit mine with inclined base

A construction method and technology of open-pit mines, applied in infrastructure engineering, ground mining, earthwork drilling and mining, etc., can solve problems such as low steps in internal dumps, low friction and erosion at the base of inclined open-pit mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

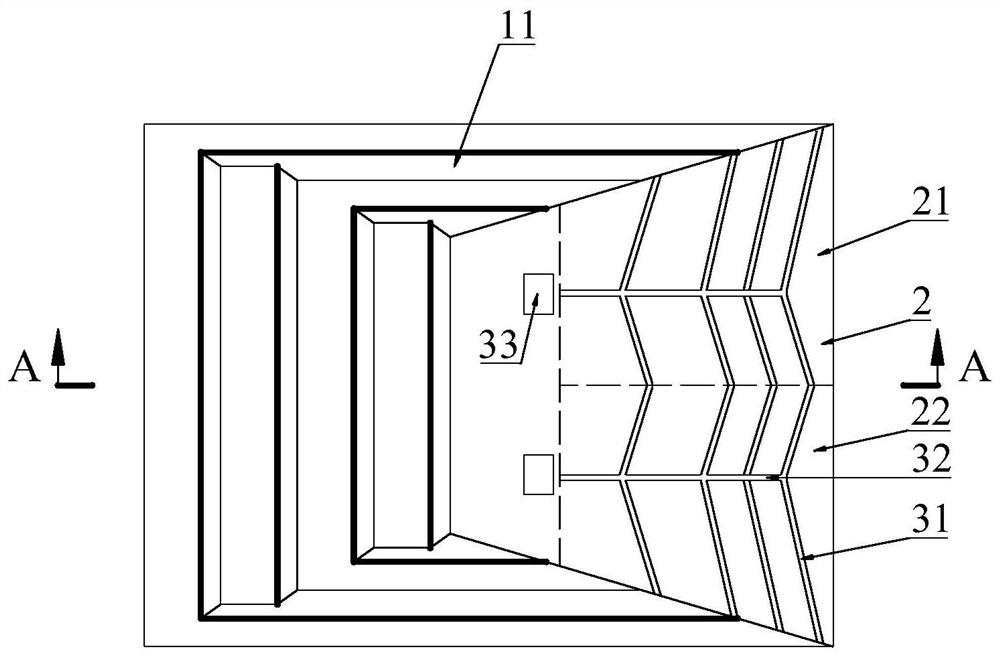

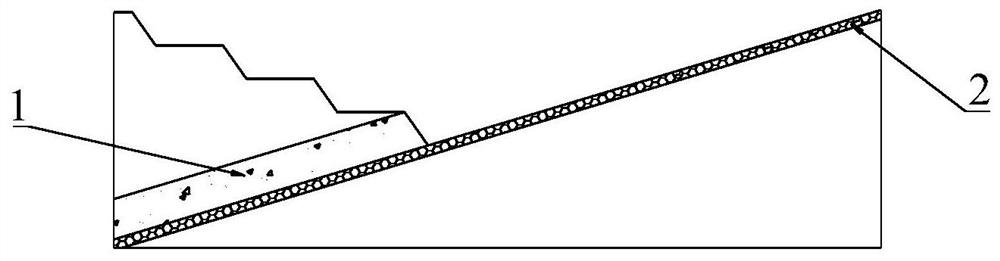

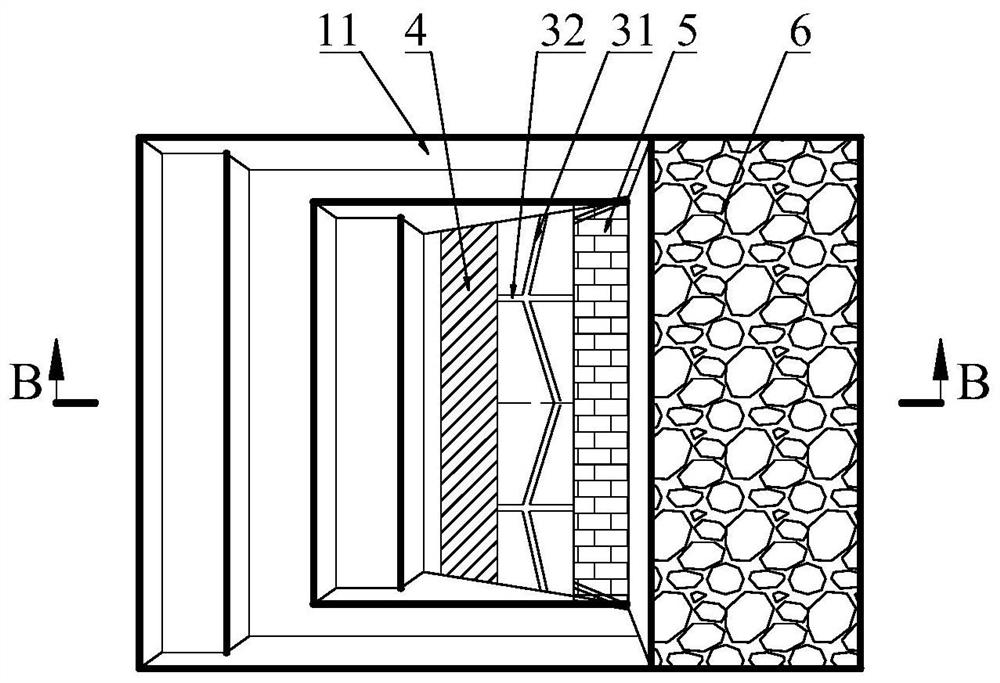

[0035] like Figure 1 to Figure 4 As shown, when the open-pit mine is mined for the first time, after the coal seam 1 is mined, the coal seam base 2 is exposed, and the width of the soil discharge step 6 is determined according to various conditions of the open-pit mine. A method for internal drainage in an open-pit mine with inclined bases proposed by the present invention includes:

[0036] Arranging catchment ditches 32: In a step area, along the direction of the coal seam base 2, it is divided into several catchment areas. the stepped area extends from top to bottom;

[0037] Arrangement of hydrophobic anti-skid ditch 31: in each catchment area, a plurality of parallel hydrophobic anti-skid ditch 31 is arranged on both sides of the water collection ditch 32, and the hydrophobic anti-skid ditch 31 is arranged obliquely along the direction of the coal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com