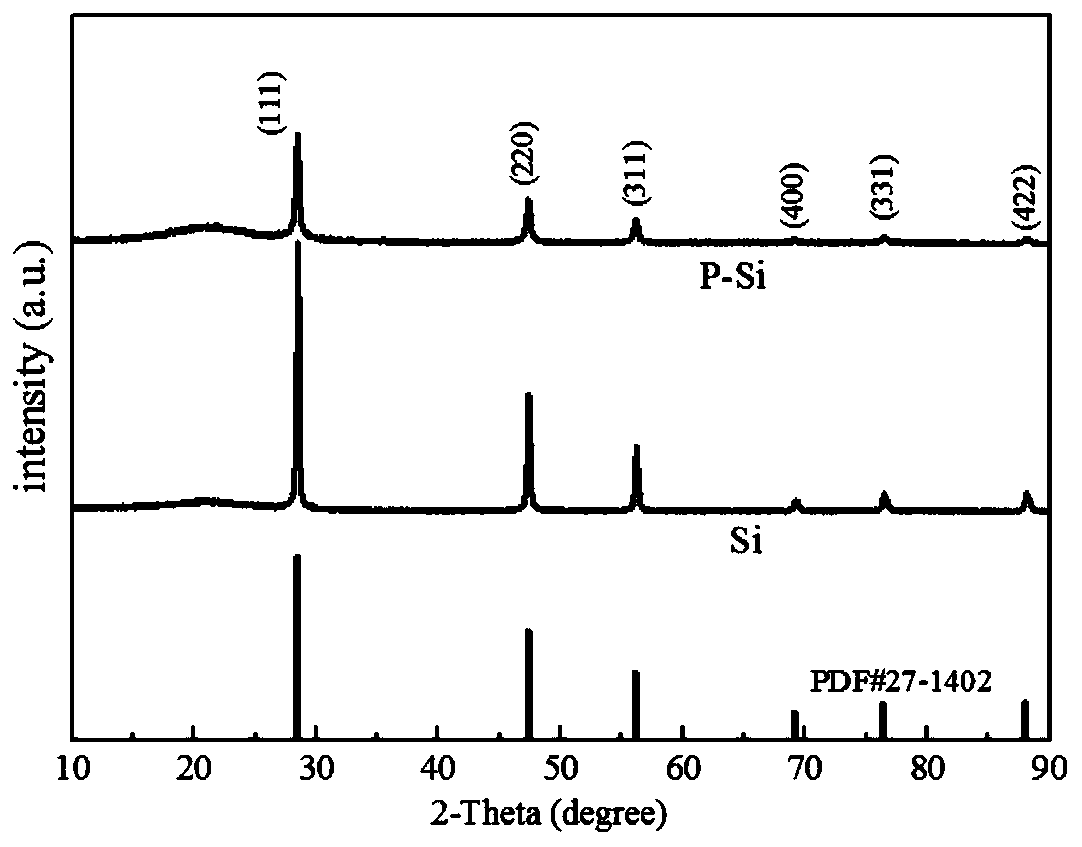

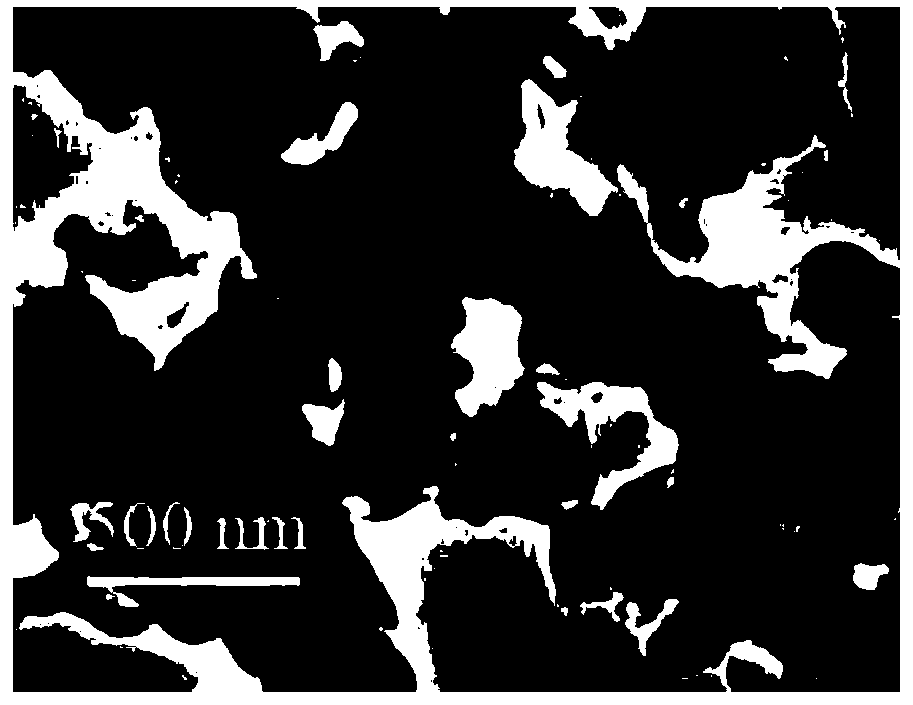

Phosphor-doped nano silicon lithium ion battery negative material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited conductivity improvement of composite materials, unsuitable for industrial production, active metal powdering, etc., and achieve electrochemical cycle performance. Stabilization, improve structural stability and cycle performance, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A phosphorus-doped nano-silicon lithium-ion battery negative electrode material and a preparation method thereof. The preparation method described in this embodiment is:

[0025] 1) According to the liquid-solid ratio of 3-4L / Kg, add elemental silicon nanomaterials into the ethanol solution, and stir for 20-30 minutes to obtain nano-silicon ethanol slurry.

[0026] 2) According to the molar ratio of Si:P being 1:0.0094~0.0120, adding the phosphorus source into the nano-silicon ethanol slurry, stirring for 20-30min to obtain the mixed slurry; then mixing the mixed slurry at 60-80 Dry under the condition of ℃ for 1.0-2.0 hours to obtain the mixed material I.

[0027] 3) The mixed material I is placed in a tube furnace, kept in a protective atmosphere at 750-850° C. for 8-10 hours, and cooled to room temperature with the furnace to obtain the mixed material II.

[0028] 4) According to the liquid-solid ratio of 40-50L / Kg, the mixed material II is added to a solution of h...

Embodiment 2

[0036] A phosphorus-doped nano-silicon lithium-ion battery negative electrode material and a preparation method thereof. The preparation method described in this embodiment is:

[0037] 1) According to the liquid-solid ratio of 4-5 L / Kg, add the elemental silicon nano-material into the ethanol solution, and stir for 20-30 min to obtain nano-silicon ethanol slurry.

[0038] 2) According to the Si:P molar ratio of 1:0.0120~0.0240, add the phosphorus source into the nano silicon ethanol slurry, stir for 20~30min to obtain the mixed slurry; then mix the mixed slurry at 60~80 Dry under the condition of ℃ for 1.0-2.0 hours to obtain the mixed material I.

[0039] 3) The mixed material I is placed in a tube furnace, kept in a protective atmosphere at 850-950° C. for 6-8 hours, and cooled to room temperature with the furnace to obtain the mixed material II.

[0040] 4) According to the liquid-solid ratio of 45-55L / Kg, the mixed material II is added to a solution of hydrofluoric acid...

Embodiment 3

[0046] A phosphorus-doped nano-silicon lithium-ion battery negative electrode material and a preparation method thereof. The preparation method described in this embodiment is:

[0047] 1) According to the liquid-solid ratio of 5-6L / Kg, add elemental silicon nanomaterials into the ethanol solution, and stir for 20-30 minutes to obtain nano-silicon ethanol slurry.

[0048] 2) According to the Si:P molar ratio of 1:0.0240~0.0360, add the phosphorus source into the nano silicon ethanol slurry, stir for 20~30min to obtain the mixed slurry; then mix the mixed slurry at 60~80 Dry under the condition of ℃ for 1.0-2.0 hours to obtain the mixed material I.

[0049] 3) The mixed material I is placed in a tube furnace, kept in a protective atmosphere at 950-1050° C. for 4-6 hours, and cooled to room temperature with the furnace to obtain the mixed material II.

[0050] 4) According to the liquid-solid ratio of 50-60L / Kg, the mixed material II is added to a solution of hydrofluoric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap