Double-rotor scrap steel crusher and crushing method

A crusher and dual-rotor technology, applied in grain processing and other directions, can solve small and thin materials such as thin plates, wire rods and chips generated in the machining process, as well as heavy scrap steel and large components, but cannot handle scrapped automobiles, Household appliances, extra-heavy scrap steel and large components, poor crushing ability of bulk materials, etc., to achieve the effect of reducing feeding chaos, reducing impact, and long crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

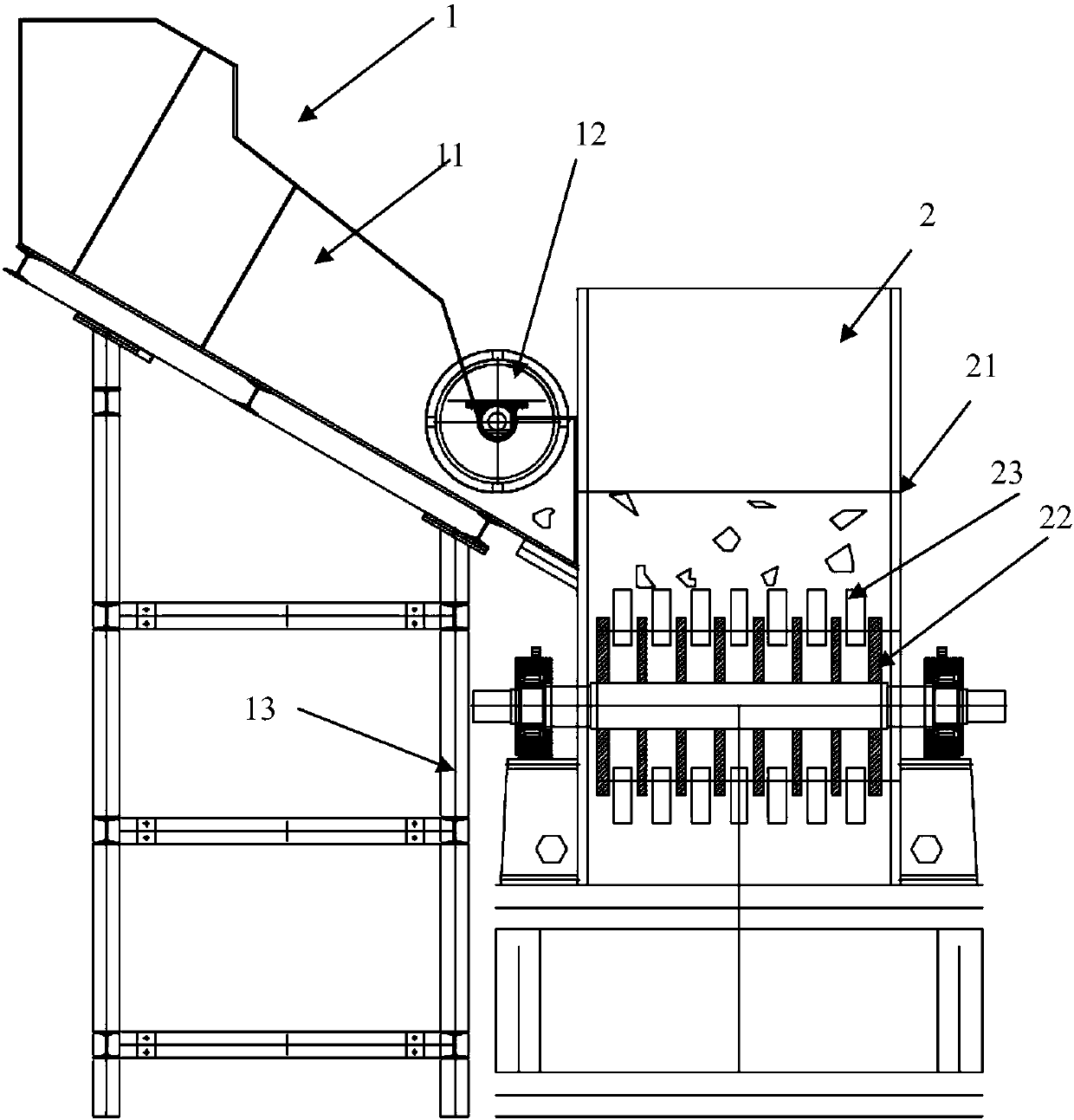

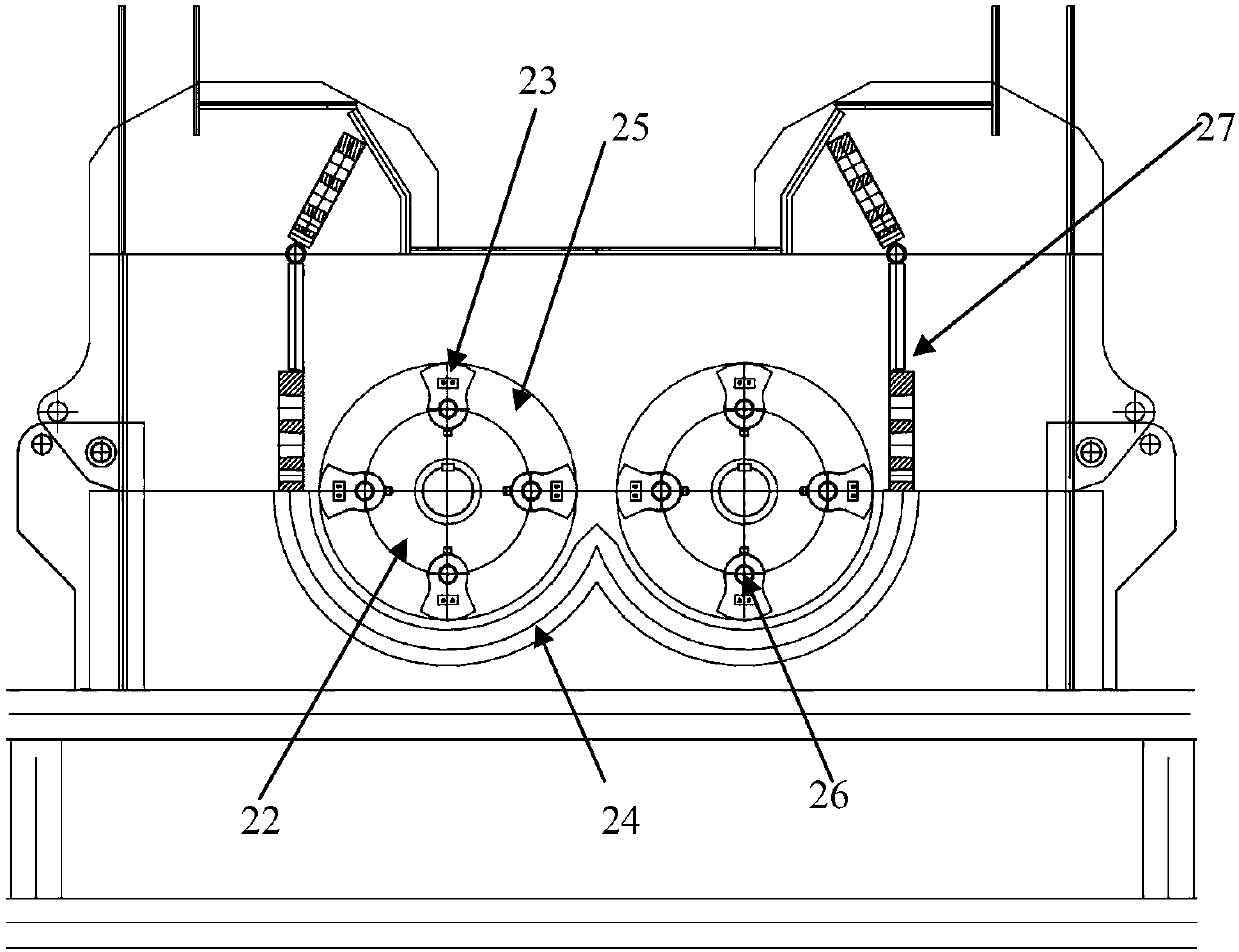

[0025] As shown in the figure, the double-rotor scrap steel crusher of the present invention includes a feed trough 1 and a crushing bin 2. The crushing bin includes a box body 21. Shaft 22, a plurality of crushing hammers 23 are arranged on the crushing shaft, and the feed port of the crushing bin is located above the end of the crushing shaft.

[0026] The invention breakthroughly adopts the way of feeding above the end side of the crushing shaft, so that the crushed material is crushed while advancing along the axial direction of the crushing shaft. The crushing time is long, and there are many crushing impact points, which can effectively crush bulk materials. Moreover, there may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com