Water spray cooling laser cutting system and cutting method thereof

A laser cutting and water mist cooling technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unsustainable cutting, hot plates, etc., achieve efficient targeted cooling, overall neatness and smoothness, guarantee Cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the present invention will be further described in detail with reference to the accompanying drawings, embodiments and effect examples, instead of limiting the present invention.

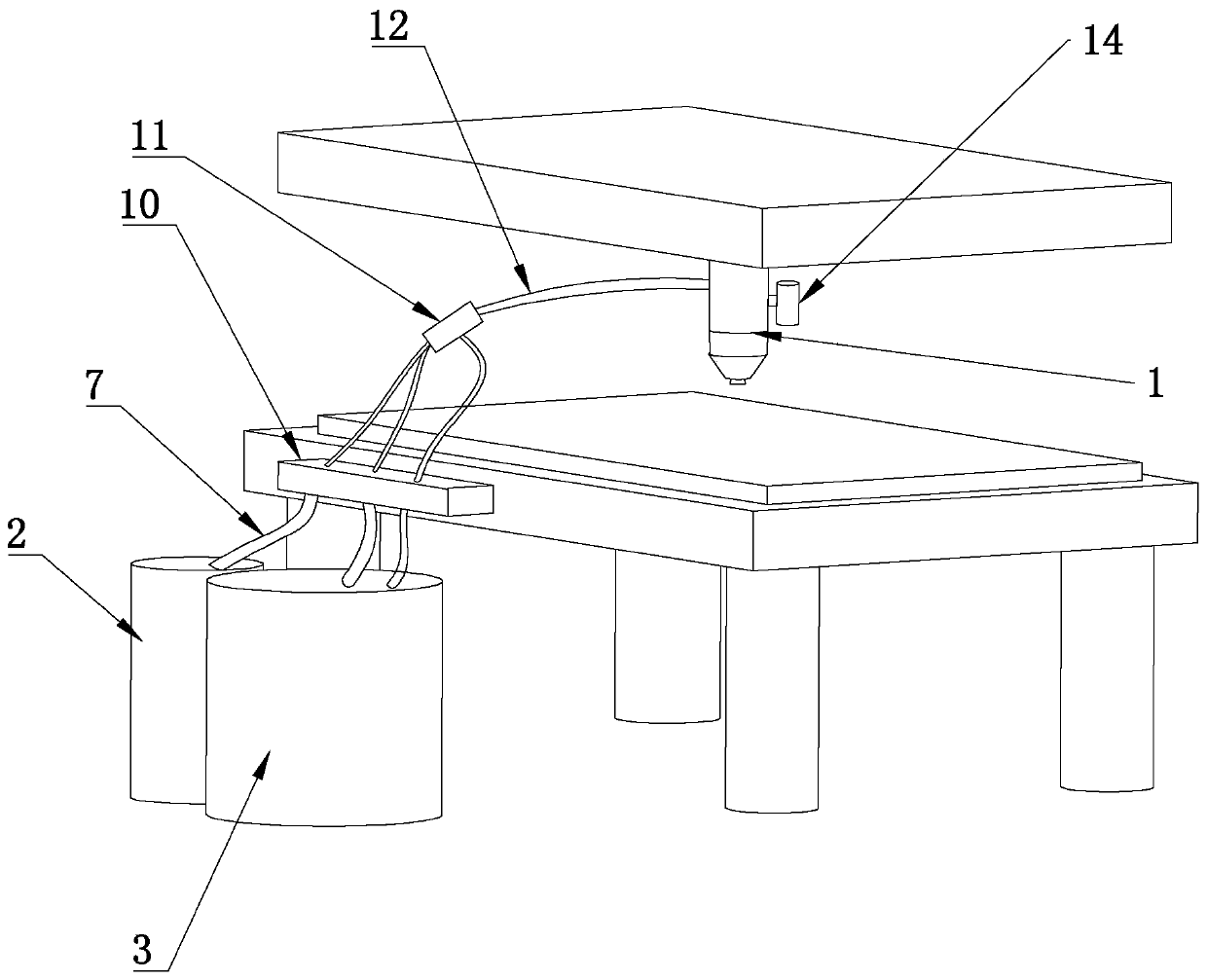

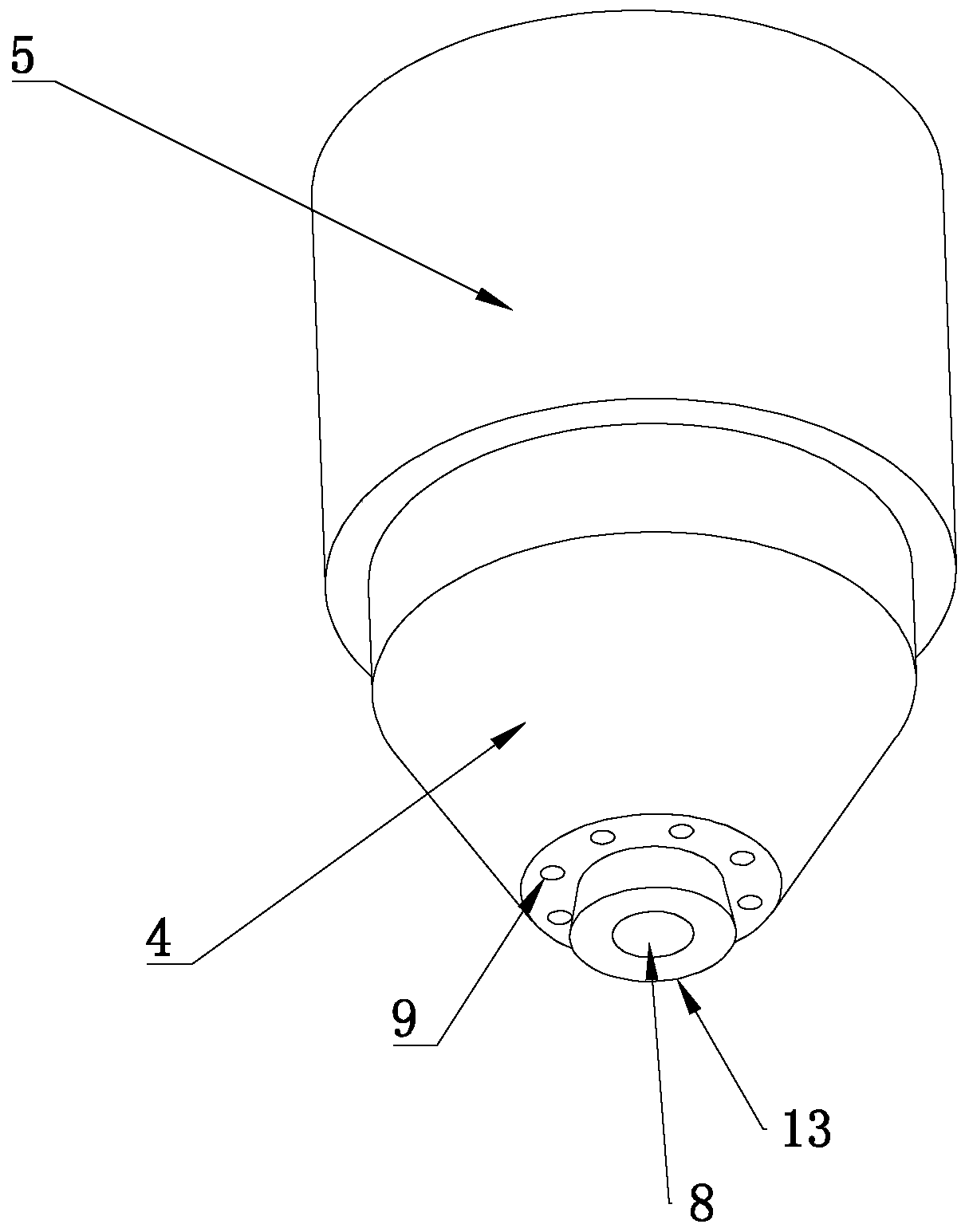

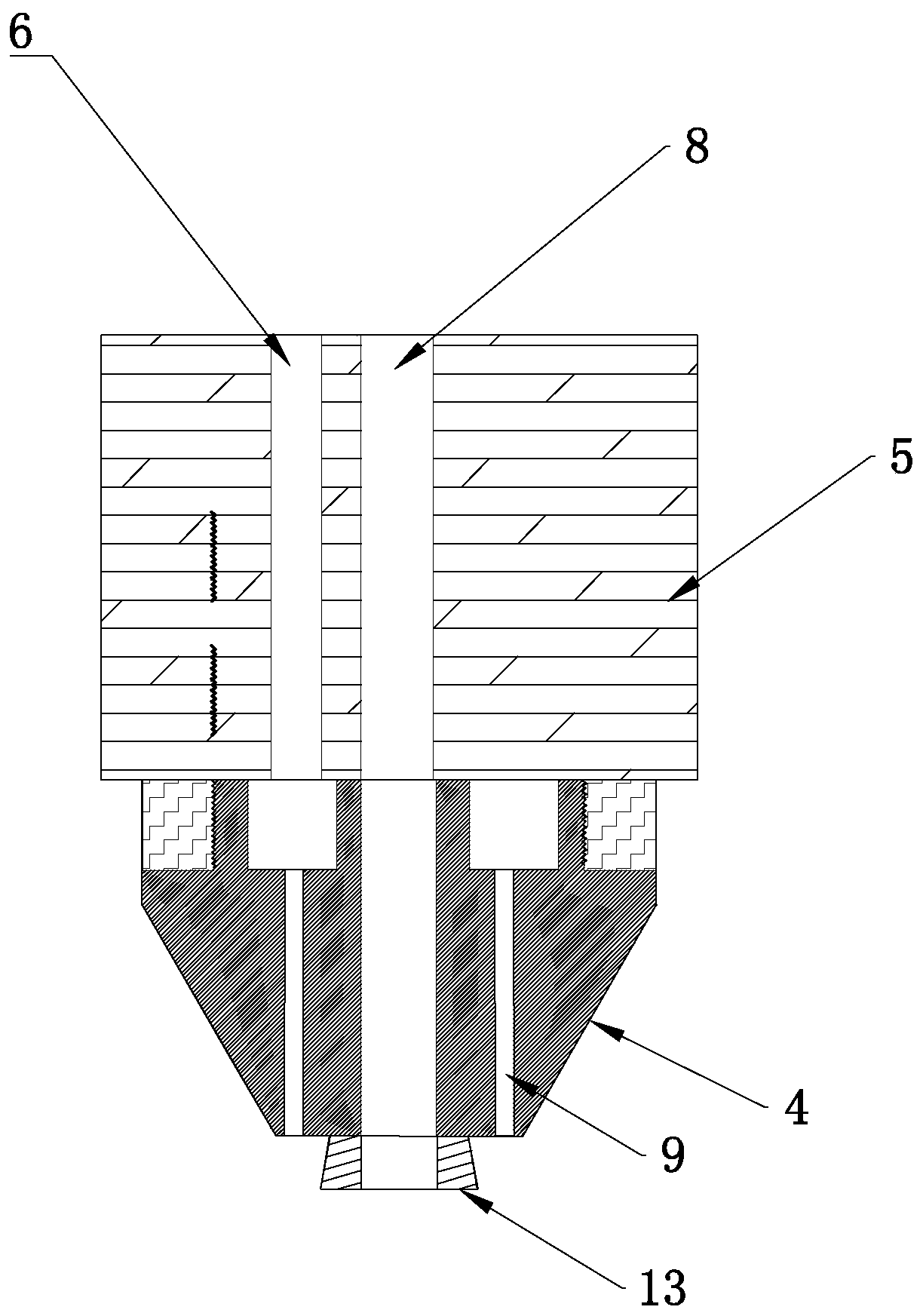

[0024] Such as Figure 1-3 As shown, a water mist cooling laser cutting system includes a cutting head 1, a water pump 2, and a compressed air pump 3. The cutting head 1 includes a nozzle 4 and a ceramic body 5. The nozzle 4 is insulated and connected to the frame through the ceramic body 5. The ceramic body 5 is provided with a water mist channel 6, a delivery pipe 7 is provided between the water pump 2, the air pump, and the water mist channel 6, and the nozzle 4 is provided with a light channel 8 through which laser light passes. 8 at the same time for the cutting gas to pass through. The cutting head 1 is provided with a number of spray holes 9 arranged around the light channel 8. When the ceramic body 5 and the nozzle 4 are connected, the water mist channel 6 and the plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com