Multilayer composite board, automobile exterior trim board and production method

A production method and technology of exterior decorative panels, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as the need for resin sheet production processes, and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

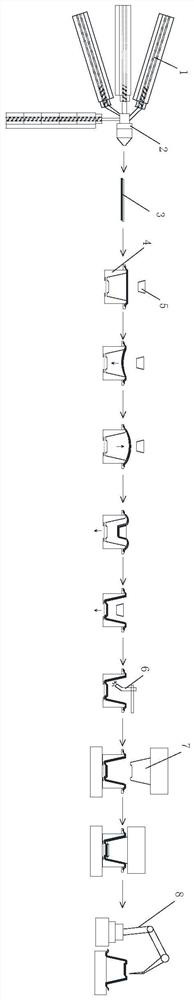

[0050] Such as Figure 1-10 Shown, the production method of automobile exterior trim panel of the present invention specifically comprises the steps:

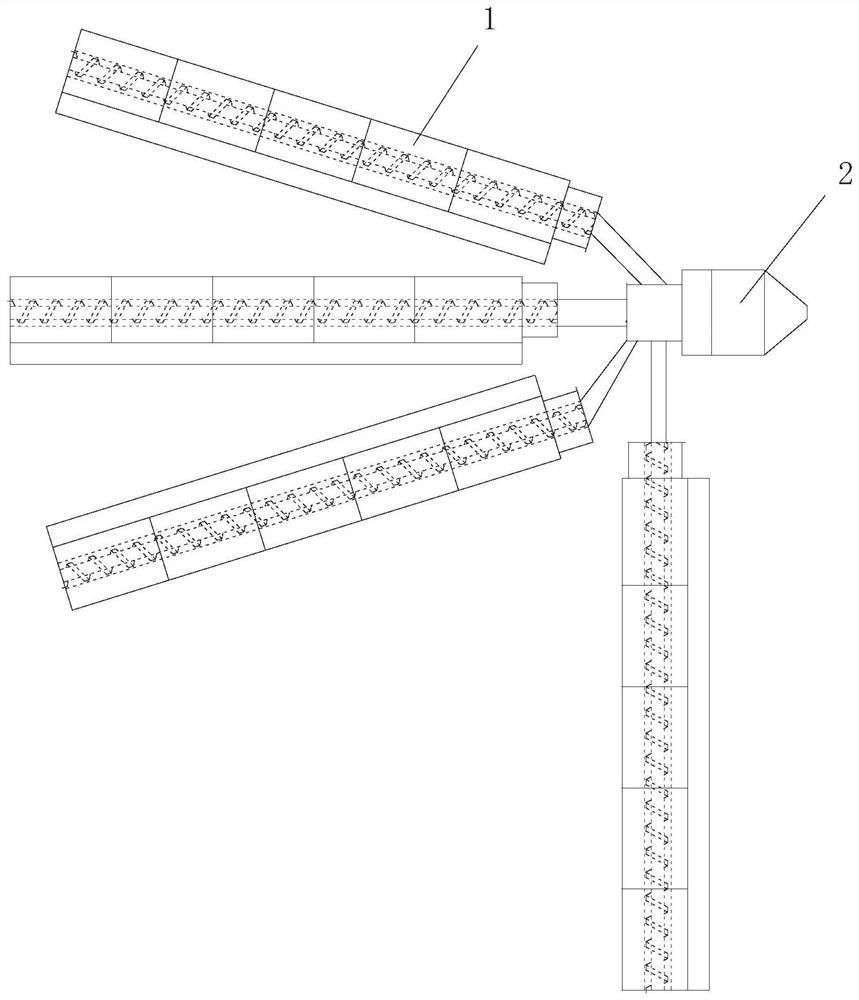

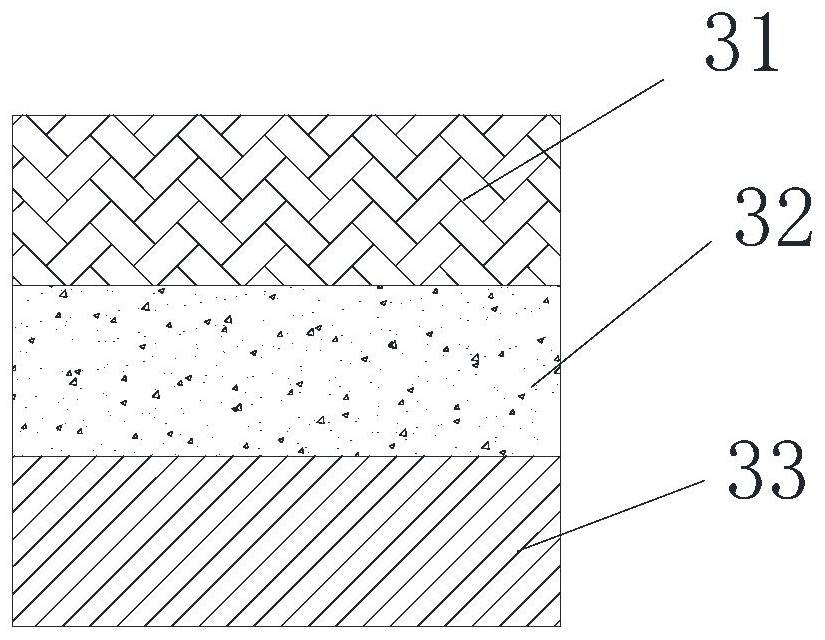

[0051] Feed the PMMA raw material, transparent ABS raw material, and ABS raw material into the extruder respectively, and extrude them through the mold, such as figure 2 As shown, the process uses a diameter of The main extruder 1 and two diameters are Auxiliary extruder 1 and 1800mm mold, the sheet can be made into various single-color, colored and special metal pearlescent color sheets, and multi-layer composite board 3 can be made. As a preferred embodiment, such as image 3 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com