Automatic bagging machine of goods

An article and automatic technology, applied in the direction of packaging, single object, transportation and packaging, etc., can solve the problems of low degree of automation, single product type, complicated bagging mechanism, etc., achieve easy maintenance, good interchangeability, and reduce maintenance difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

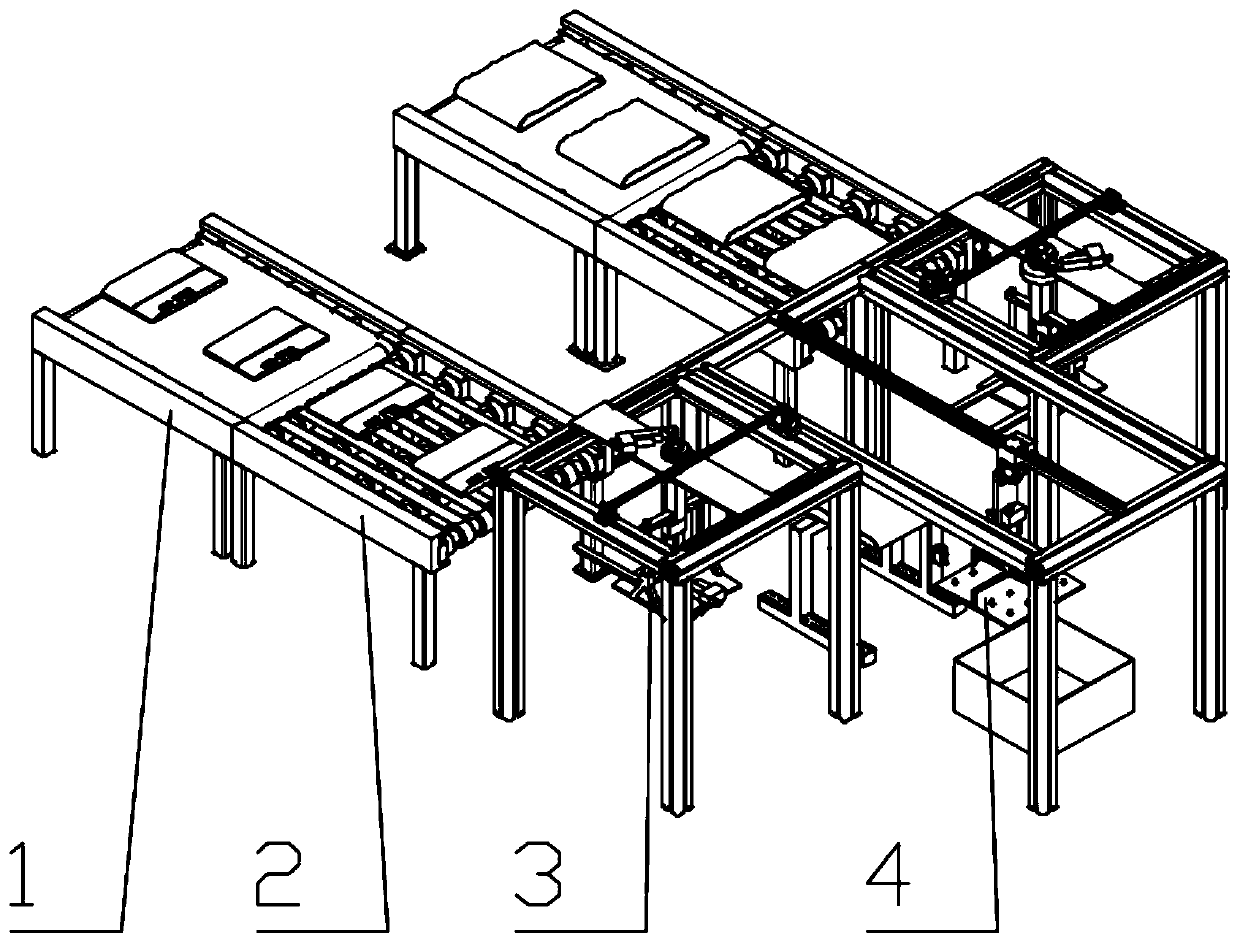

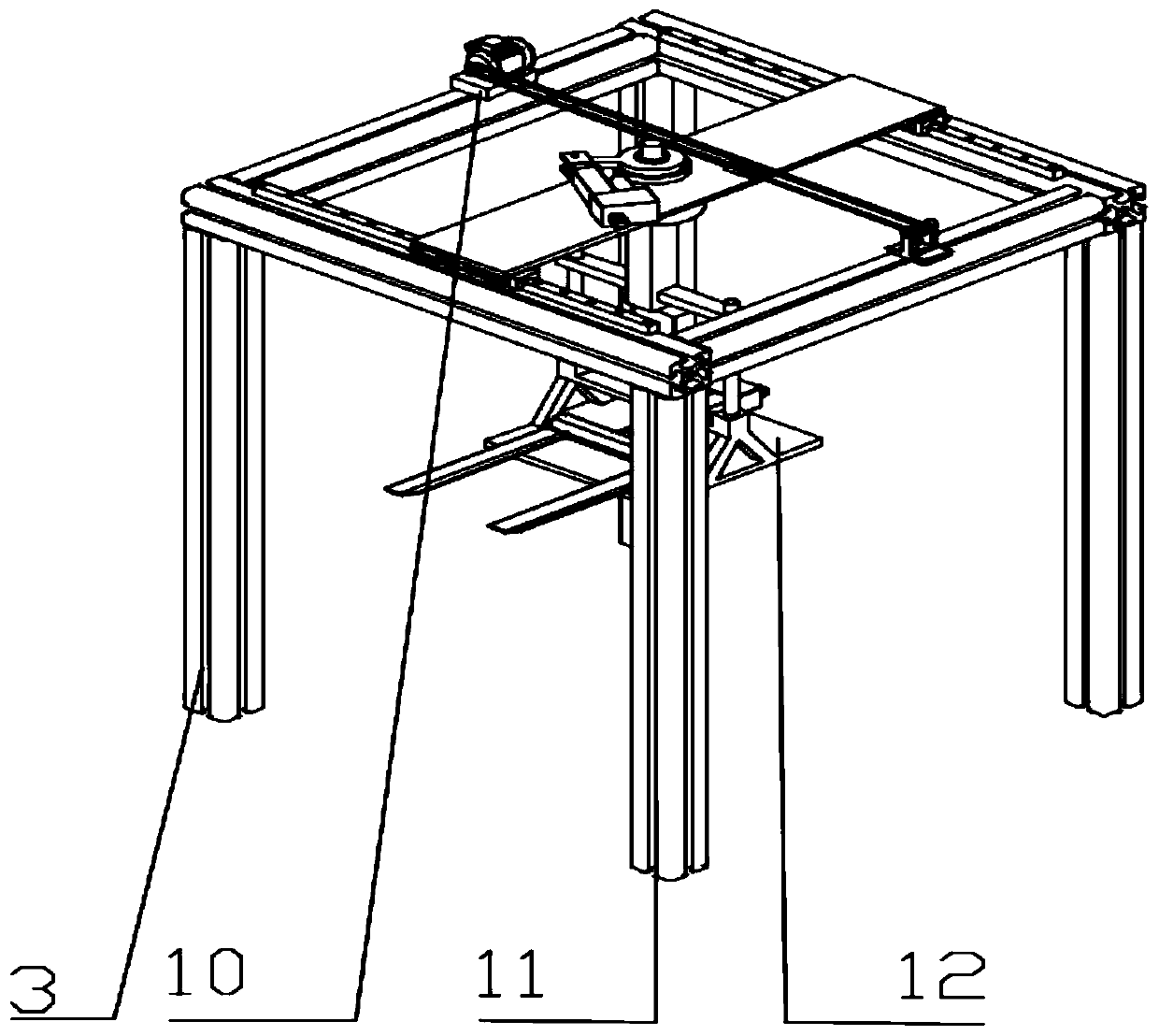

[0027] Embodiment 1: as Figure 1-11 As shown, an automatic bagging machine for articles, including a custom-made conveyor belt conveying mechanism 2, a display lifting and turning mechanism 3, and a packaging bag suction and transport mechanism 4; wherein the custom-made conveyor belt conveying mechanism 2 is used to transport articles and provide a display lifting and turning mechanism 3. A platform for picking up items; the display lifting steering mechanism 3 is used to lift items and deliver the items to the packaging bag opened by the packaging bag suction transport mechanism 4; the packaging bag suction transport mechanism 4 is used to open the packaging bag.

[0028] Further, it can also include a common conveyor belt conveying mechanism. The common conveyor belt conveying mechanism 1 is located at the front end of the whole system. On the narrow conveyor belt 7 of the mechanism 2.

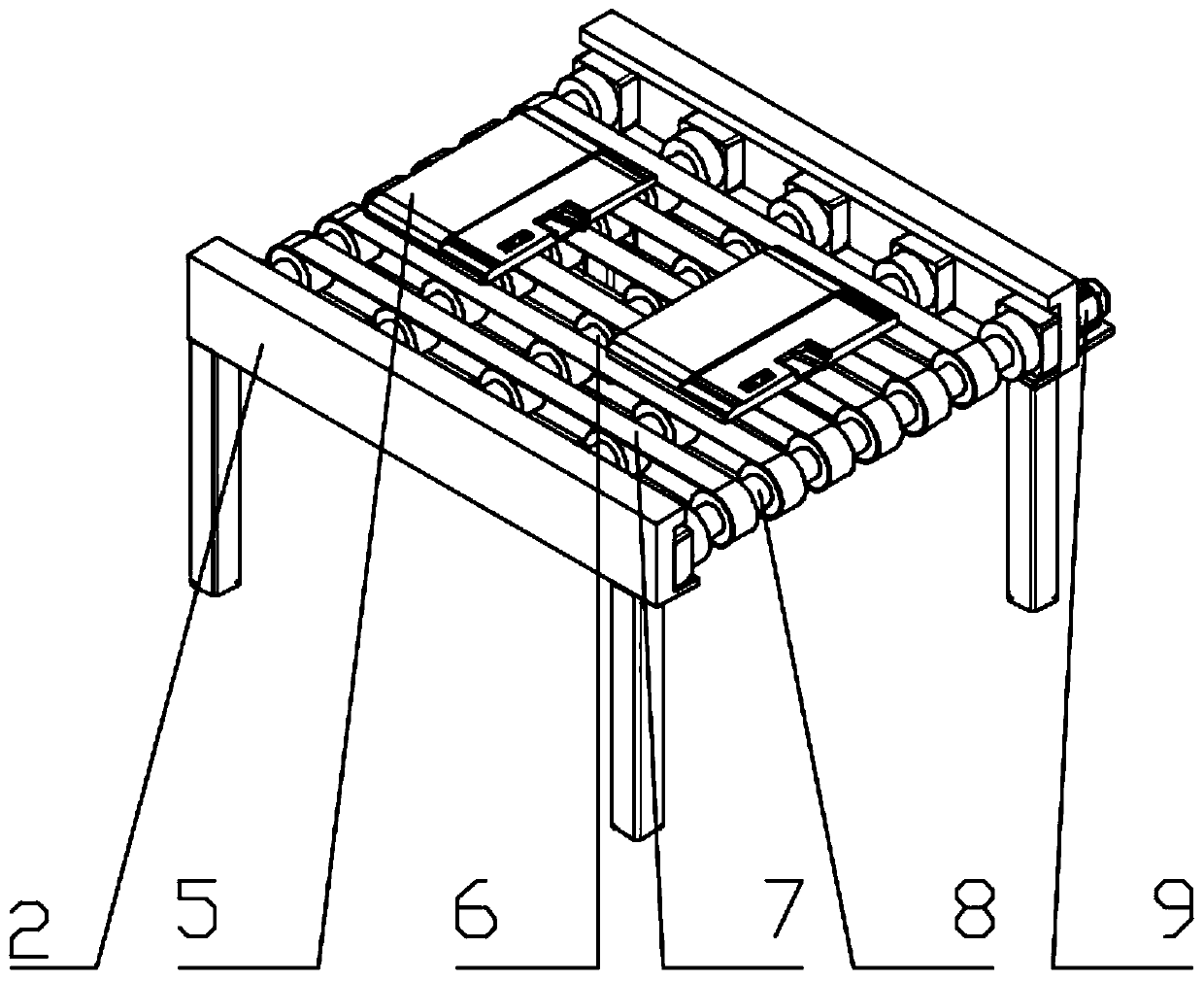

[0029] Further, the customized conveyor belt delivery mechanism 2 can be set to inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com