Brominated butyl rubber-nylon thermoplastic elastomer with air tightness and preparation thereof

A technology of brominated butyl rubber and thermoplastic elastomer, which is applied in the field of polymer elastomer preparation, can solve the problems of difficult preparation, poor compatibility of brominated butyl rubber and nylon, and the compatibility effect of brominated butyl rubber and nylon Unsatisfactory and other problems, to achieve the effect of excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Masterbatch preparation:

[0031] Set the rotational speed of the torque rheometer to 50 rpm and the temperature to 50°C. At 0 min, add 50 g of BIIR raw rubber; at 1.5 min, add anti-aging additives such as RD 1 g and MB 1 g; at 3 min, add 5 g of plasticizer naphthenic oil; at 12 min, glue out to obtain masterbatch.

[0032] Preparation of Bromobutyl Nylon Thermoplastic Elastomer:

[0033] At 0 min, add the above-mentioned masterbatch and nylon 50g, compatibilizer low-melting point polypropylene grafted maleic anhydride 5g and antioxidant 1010 and antioxidant 168, a total of 0.2g, mix at 180°C for 3 minutes, add vulcanizing agent DCP 1g , and then dynamically vulcanized for 6 minutes, bromobutyl rubber nylon thermoplastic elastomer can be obtained.

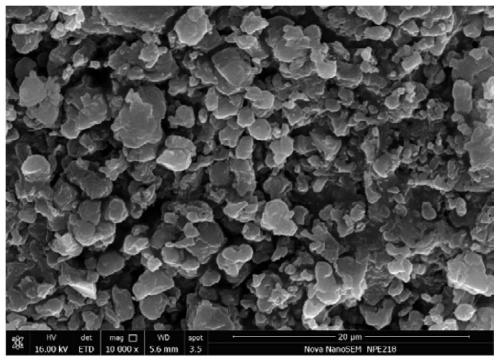

[0034] The SEM pictures and optical pictures of the brominated butyl rubber nylon thermoplastic elastomer prepared in the present embodiment are respectively as follows figure 1 and figure 2 as shown, figure 1 It is th...

Embodiment 2

[0036] Masterbatch preparation method: set the rotational speed of the torque rheometer at 50 rpm and the temperature at 50°C. At 0 min, add 60 g of BIIR raw rubber; at 1.5 min, add anti-aging additives such as RD 1 g and MB 1 g; at 3 min, add 5 g of plasticizer naphthenic oil; at 12 min, glue out to obtain masterbatch.

[0037] Preparation of Bromobutyl Nylon Thermoplastic Elastomer

[0038] At 0 min, add the masterbatch prepared above and 40g of nylon, 5g of compatibilizer low-melting point polypropylene grafted maleic anhydride, 0.2g of antioxidant 1010 and antioxidant 168, mix at 180°C for 3 minutes, add Vulcanizing agent DCP 1g, and then dynamic vulcanization for 6 minutes, can obtain brominated butyl rubber nylon thermoplastic elastomer.

Embodiment 3

[0040]Masterbatch preparation method: set the rotational speed of the torque rheometer at 50 rpm and the temperature at 50°C. At 0 min, add 70 g of BIIR raw rubber; at 1.5 min, add RD 1 g, MB 1 g and other additives; at 3 min, add 5 g of plasticizer naphthenic oil; at 12 min, glue out to obtain masterbatch.

[0041] Preparation of Bromobutyl Nylon Thermoplastic Elastomer

[0042] At 0 min, add the above-mentioned masterbatch and nylon 30g, compatibilizer low-melting point polypropylene grafted maleic anhydride 5g, antioxidant 1010 and antioxidant 168, 0.2g in total, mix at 180°C for 3 minutes, add vulcanizing agent DCP 1g, and then dynamically vulcanized for 6 minutes to obtain brominated butyl rubber nylon thermoplastic elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com