A double hydraulic automatic tensioner

A tensioner, dual-hydraulic technology, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of easy damping, aggravating the wear of damping parts, and intensifying the impact between the tensioning arm and the limit block, etc. To achieve stable damping performance, good damping performance, and improve the effect of damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is further elaborated:

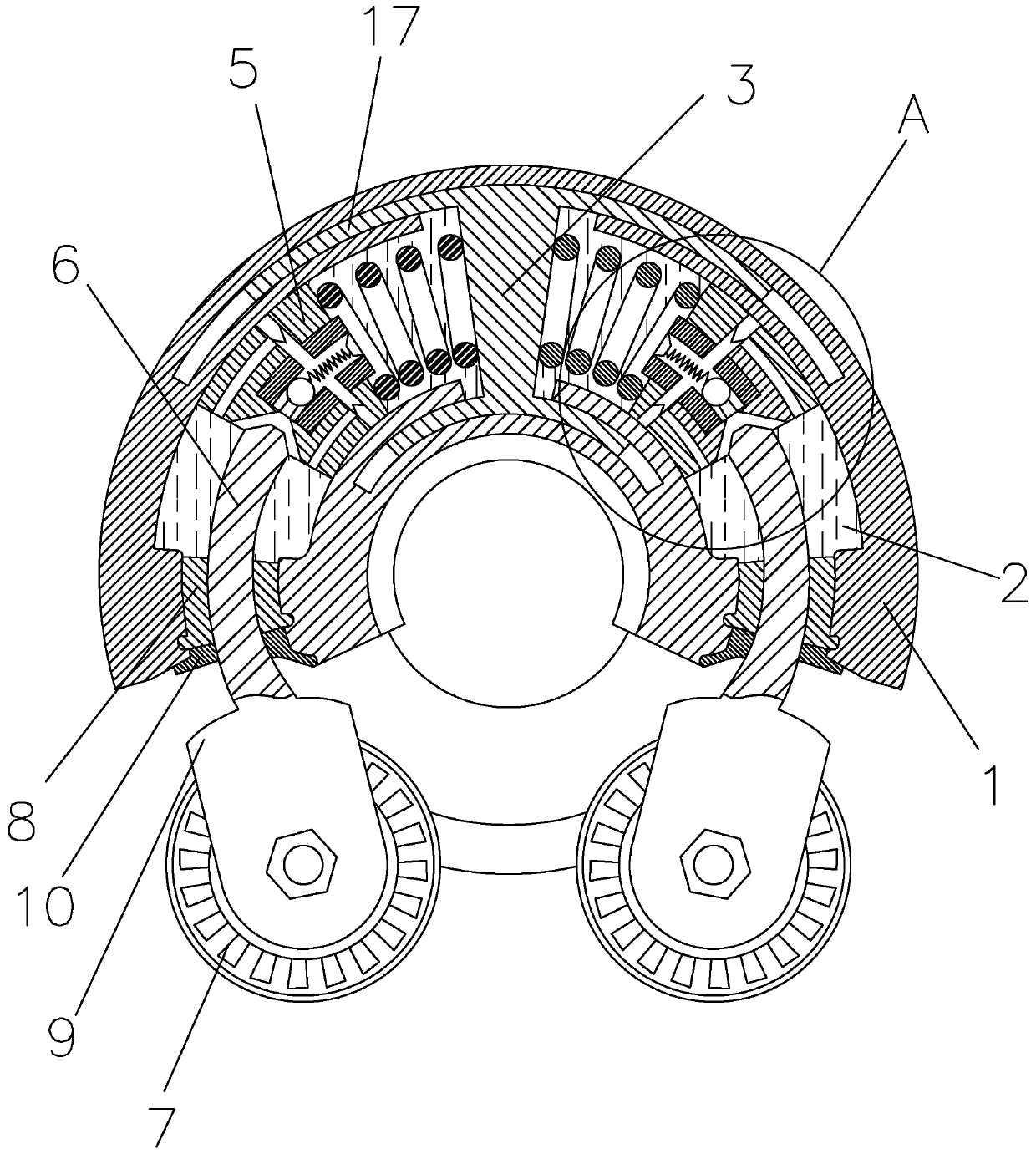

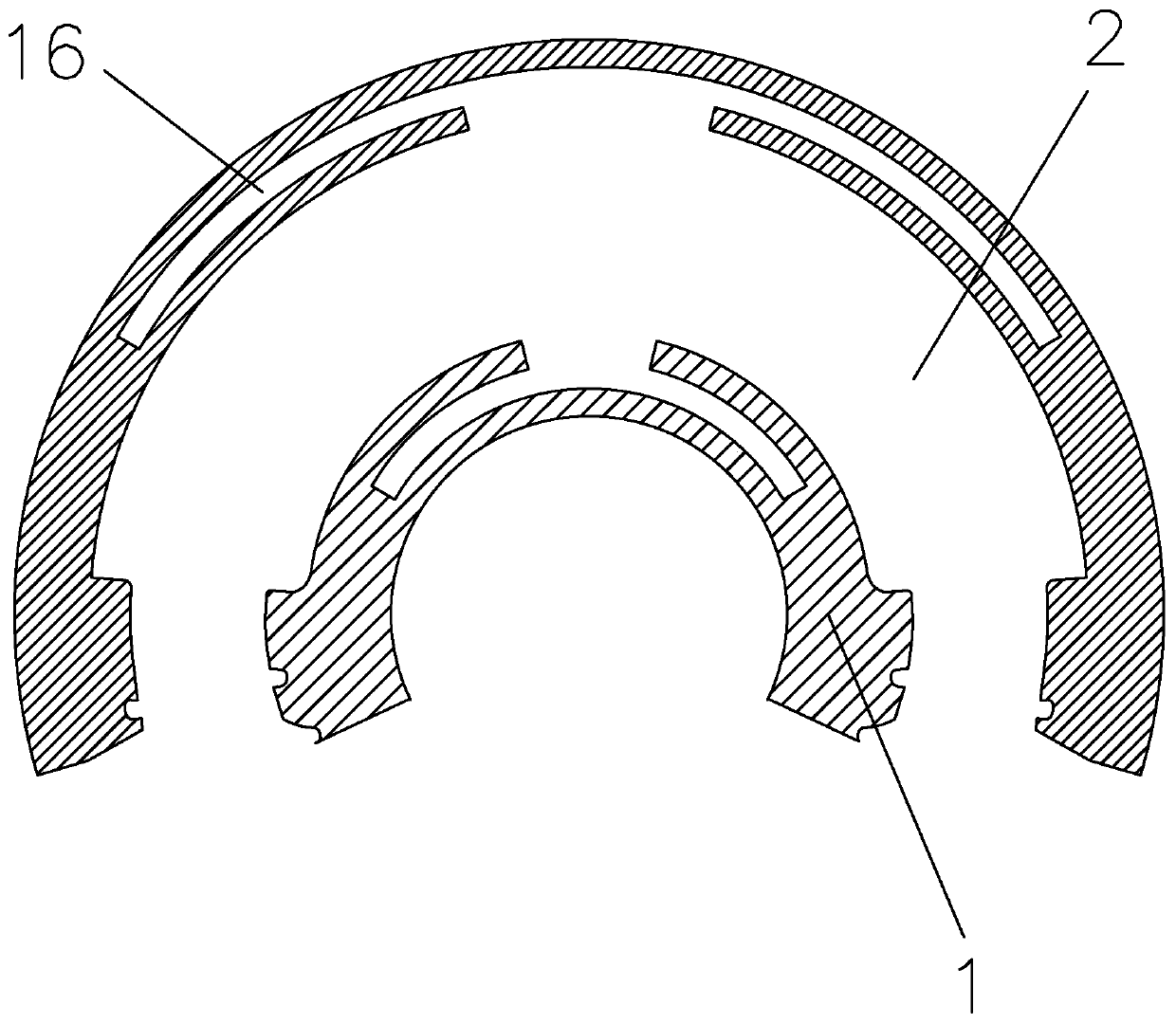

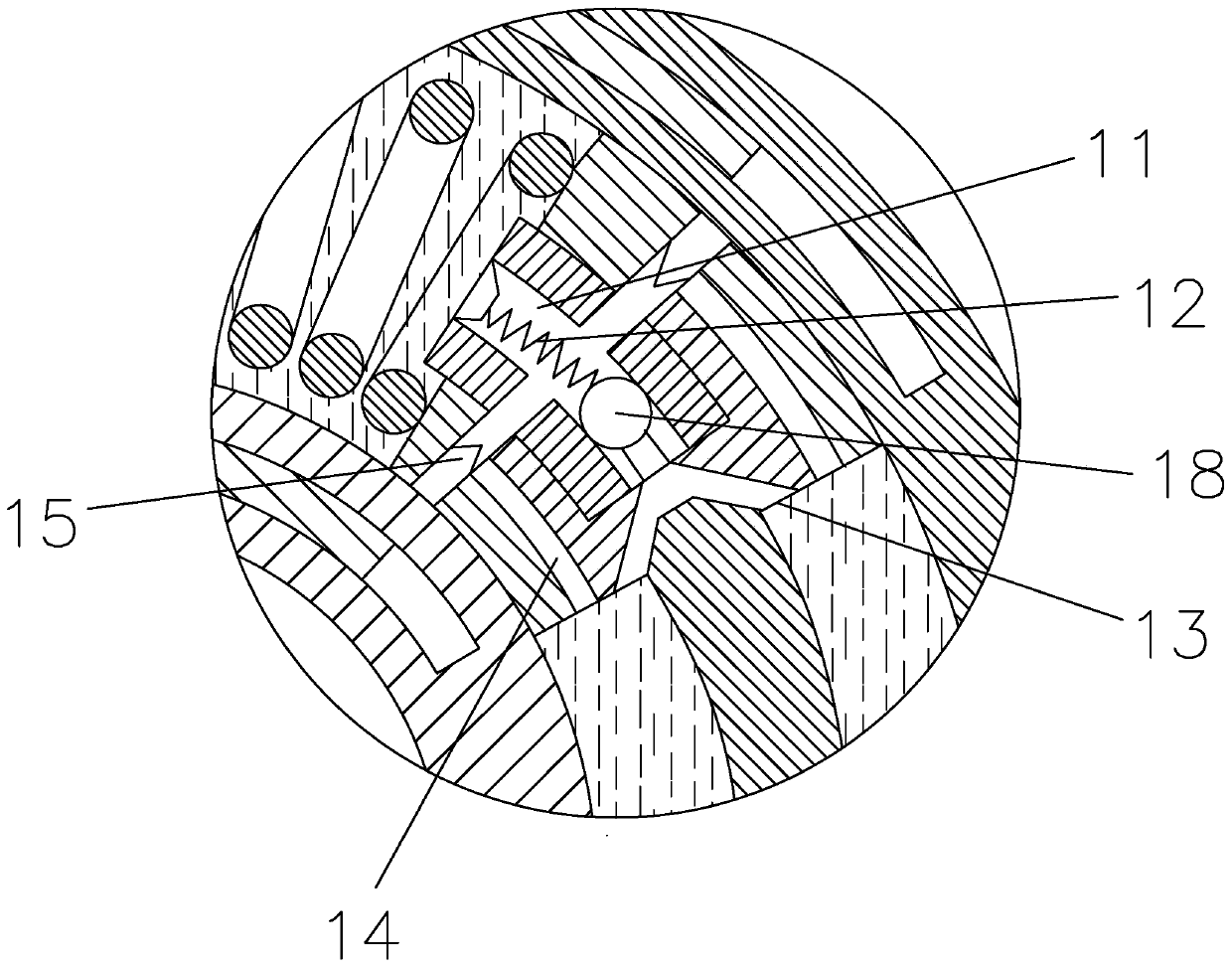

[0020] figure 1 , figure 2 and image 3 It is a double hydraulic automatic tensioner, including a cylinder body 1 with a C-shaped structure, and a long channel 2 is provided from one end of the cylinder body 1 to the other end, and a damping fluid is provided in the channel 2, and the channel The middle part of the 2 is provided with a movable stopper 3 adapted to the passage 2, and the movable stopper 3 is slidingly connected with the cylinder body 1, and the passage 2 is provided with two pistons 5 and two springs. The spring is located between the pistons 5, the movable stopper 3 is located between the springs, one end of the spring rests on the piston 5, the other end of the spring rests on the movable stopper 3, the channel 2 A piston rod 6 is inserted at both ends, and one end of each piston rod 6 is connected to its corresponding piston 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com