Fast-heating plate electric heating device with precise temperature control

An electric heating device and precise technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of slow heating speed and inaccurate temperature measurement, achieve fast heating speed, improve temperature range, structure Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

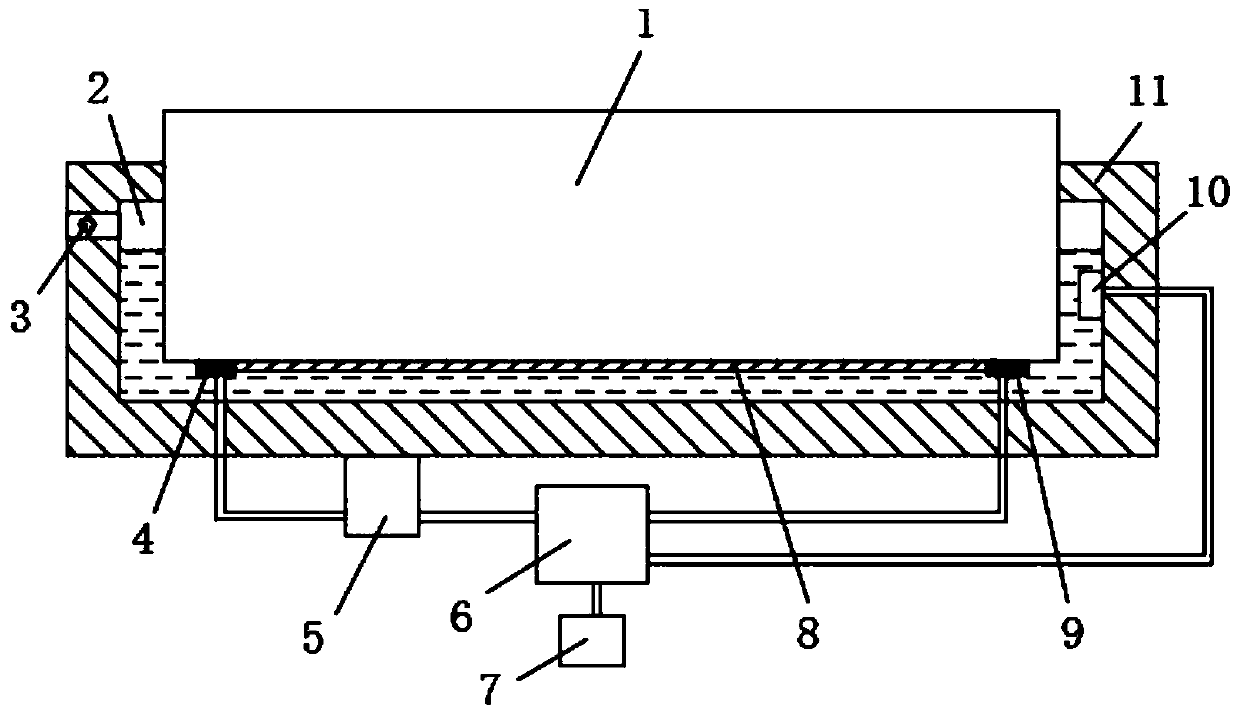

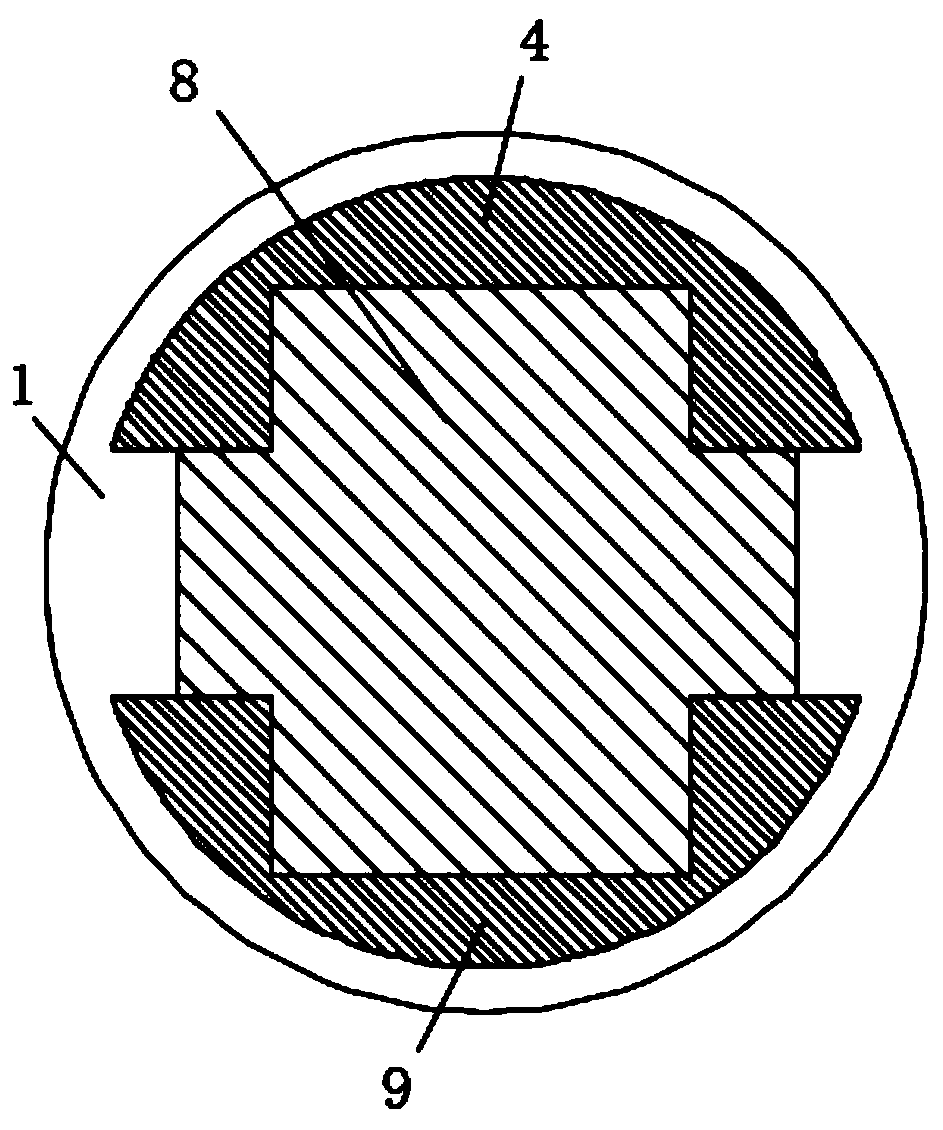

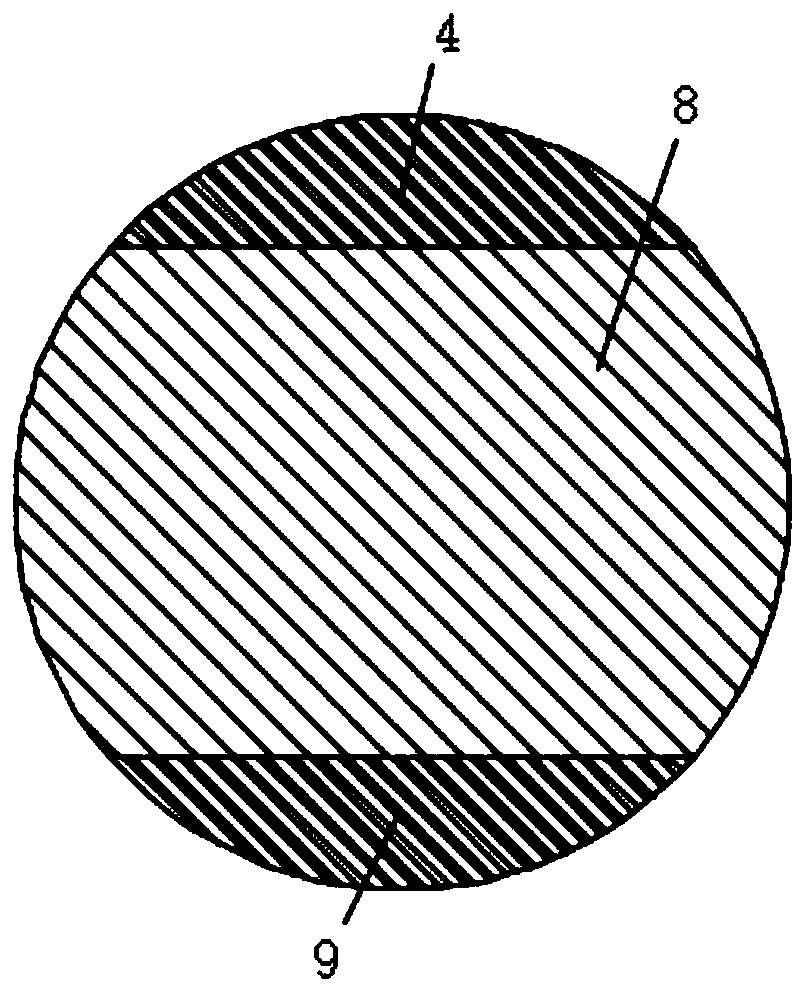

[0018] refer to Figure 1-4 , a fast heating plate electric heating device with precise temperature control, comprising an electric heating plate 1, the electric heating plate 1 is one of an inorganic plate, a quartz plate, a ceramic plate, a high borosilicate glass plate, and a metal plate with an insulating coating The bottom of the electric heating plate 1 is provided with a shell 11, the shell 11 is sealed and connected with the electric heating plate 1, the bottom of the electric heating plate 1 is provided with a nano-film electric heating device, the gap between the electric heating plate 1 and the shell 11 is filled with heat transfer oil, and the shell 11 Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap