Hot press processing device and hot press processing method

A processing device and processing method technology, applied in the direction of quenching device, metal processing equipment, forming tools, etc., can solve the problems of delayed damage, high product cost, high cost of pressed and formed products, etc., and achieve low cost and working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

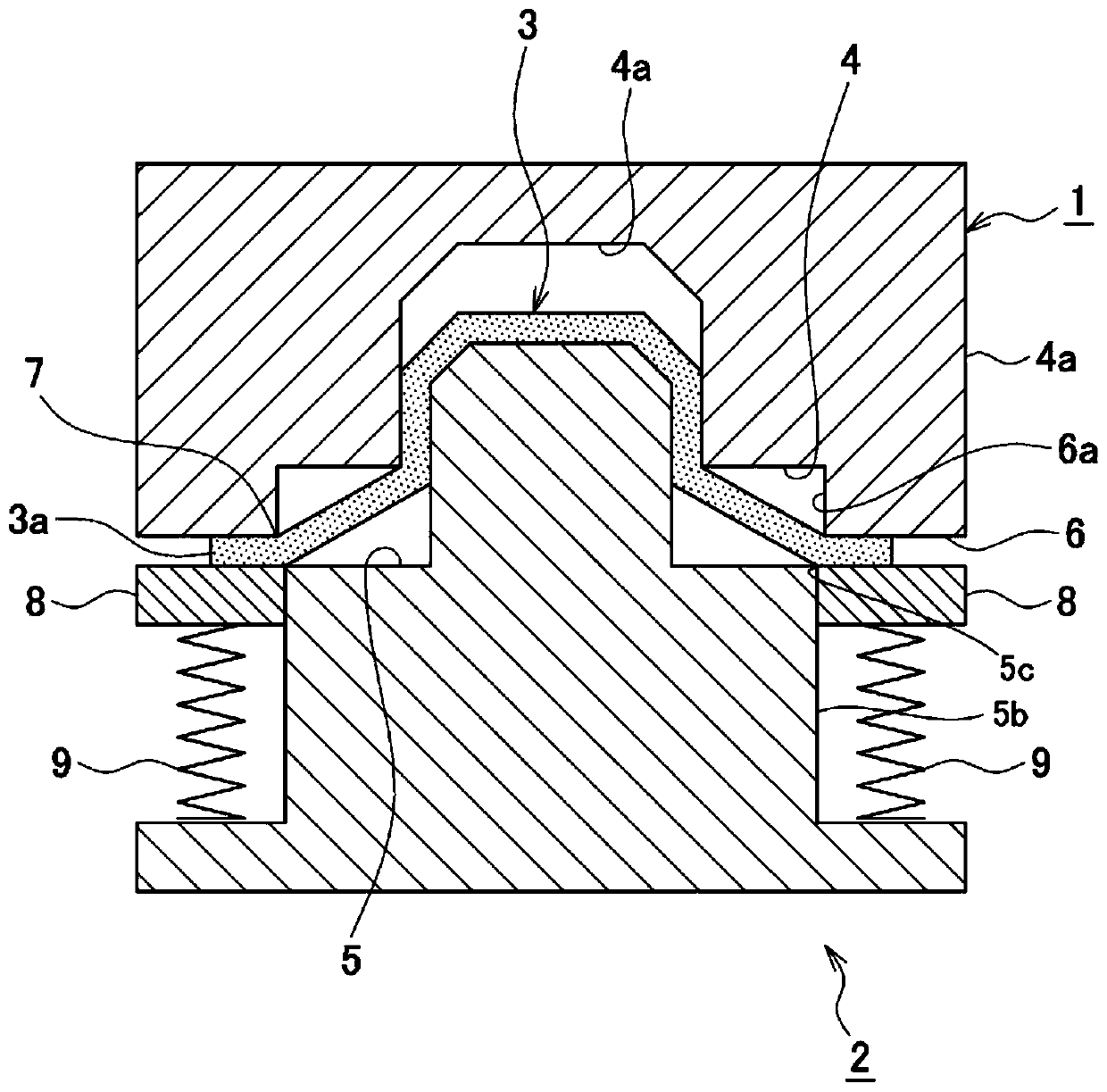

[0040] According to the hot press working device and the hot press working method using such a device according to the embodiments of the present invention, it is possible to avoid the occurrence of burrs on the press-formed product due to the cutting process in the hot press forming process, thereby eliminating the need for post-forming operations. The deburring operation can reduce the man-hours of the operation, thereby realizing the cost reduction of the product.

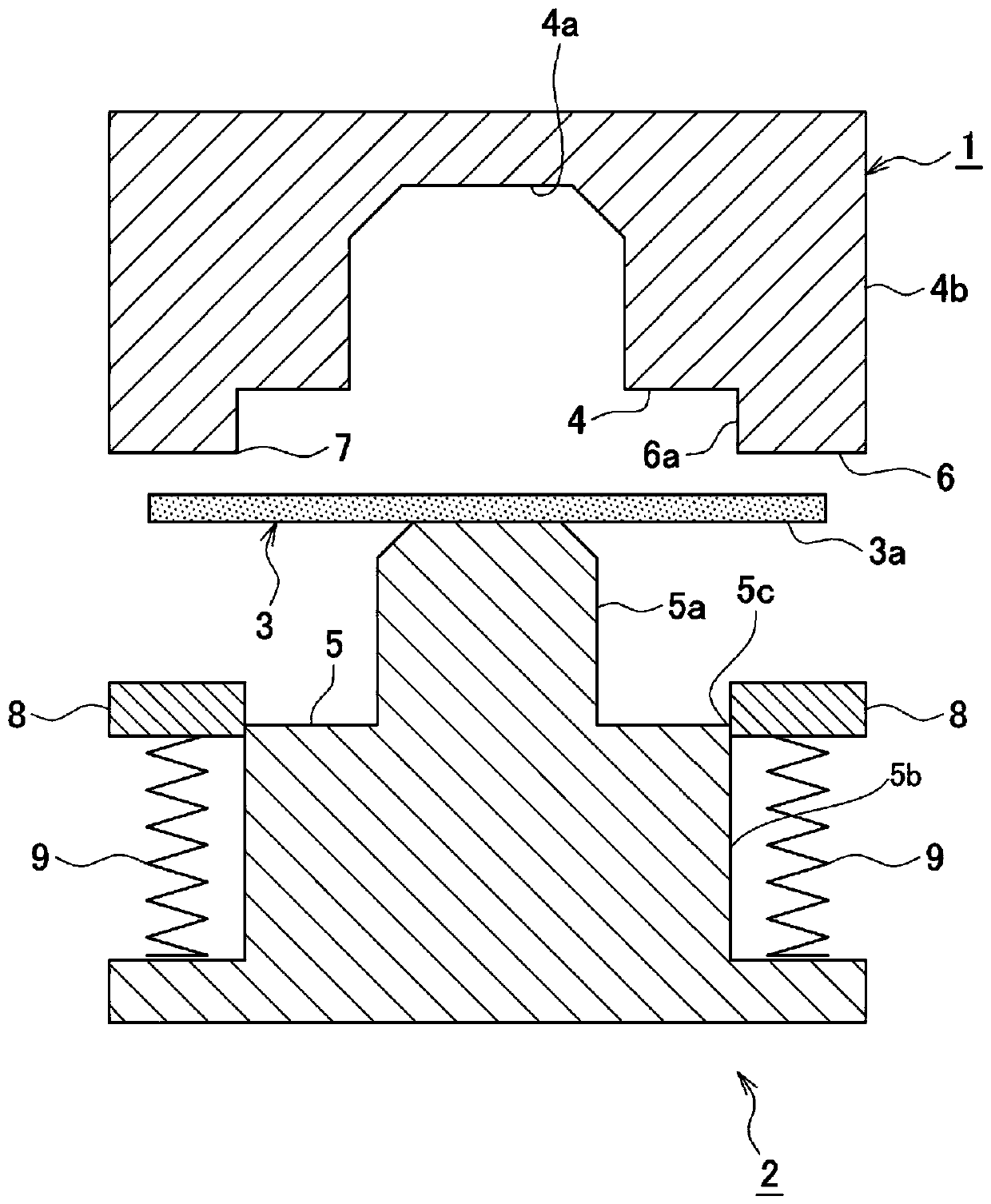

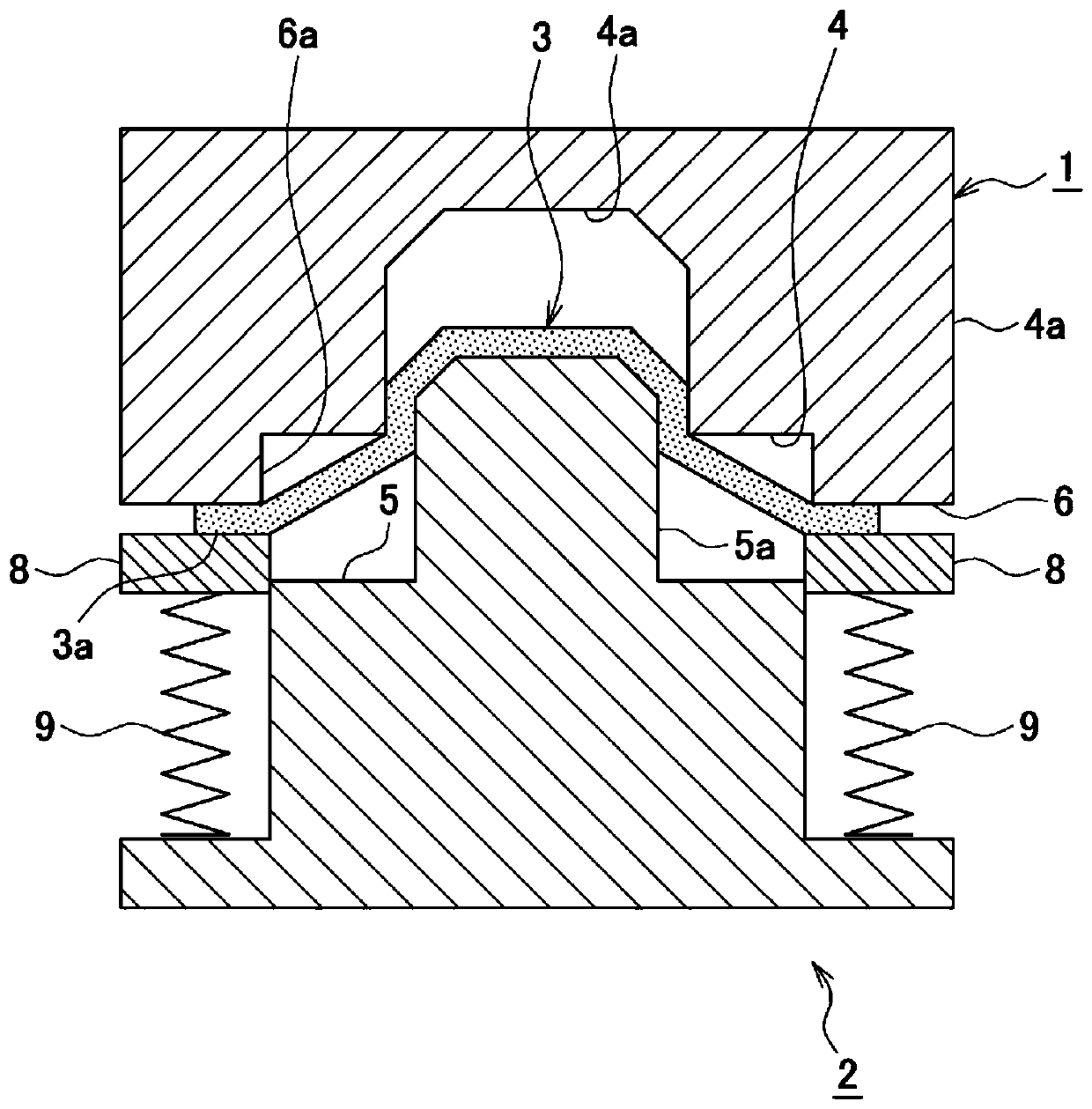

[0041] Next, use Figure 1 ~ Figure 4 , the hot press processing apparatus according to the embodiment of the present invention will be described.

[0042] The hot press processing apparatus according to the embodiment of the present invention has a die composed of a die 1 as a movable die and a punch 2 as a fixed die, as in the prior art. Furthermore, the die 1 and the punch 2 respectively have forming surfaces 4 and 5 formed to form the blank 3 into a press-formed product (not shown) having a predetermined sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com