Non-heating type shoe drying device

A non-thermal, shoe-drying technology, applied in household cleaning devices, shoe cleaning, high-efficiency power electronic conversion, etc., can solve problems such as affecting the use effect, potential safety hazards, restricting development, etc., to improve efficiency and reduce energy consumption , the effect of accelerating evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

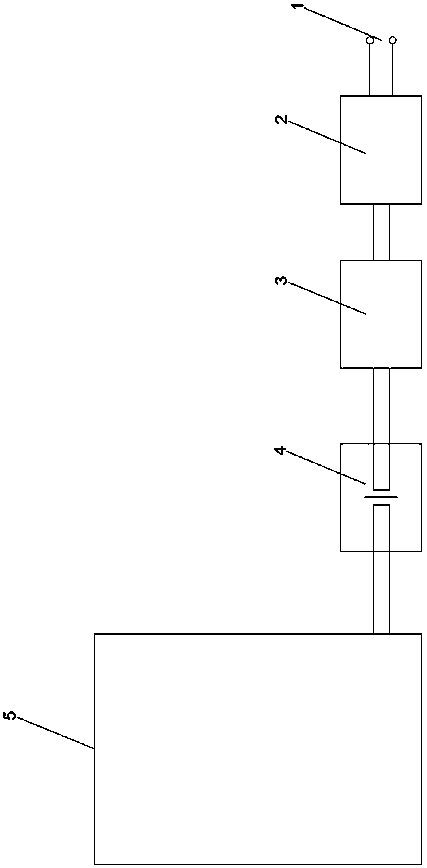

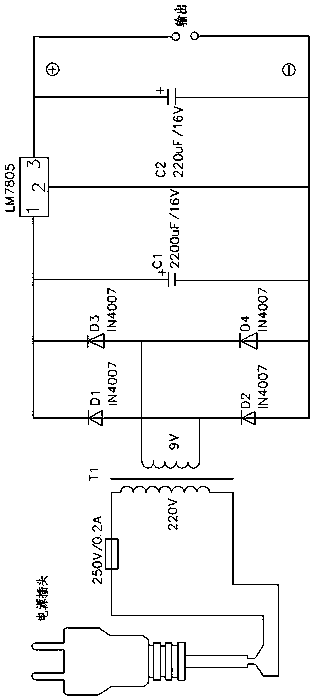

[0023] Such as Figure 1-4 As shown, a non-thermal shoe drying device includes a regulated DC power supply 2, the input terminal of the regulated DC power supply 2 is connected to the mains 1, the output terminal is connected to the input terminal of the zero voltage switch 3, and the zero voltage switch The output end of 3 is connected with the input end of high-voltage pulse generator 4, and the output end of high-voltage pulse generator 4 is connected with the drying device in shoe rack 5. The regulated DC power supply 2 adopts a 12V5A DC power supply, and the zero voltage switch 3 adopts a ZVS drive module.

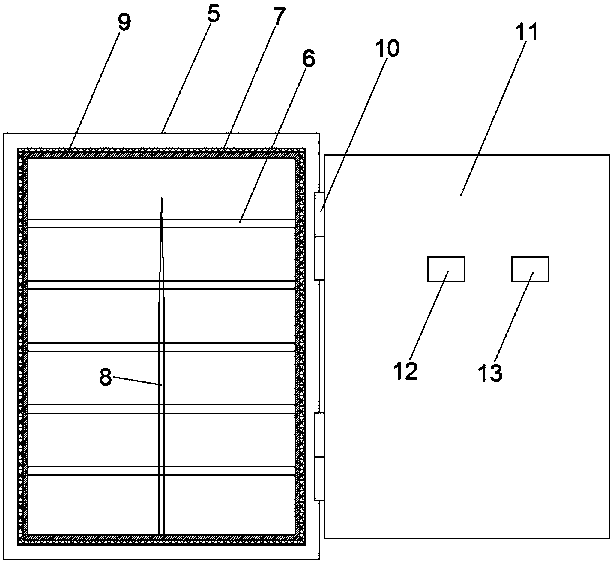

[0024] Preferably, the shoe rack 5 is provided with several layered plates 6, and the drying device is connected to include a metal mesh anode 7 and a needle-shaped cathode 8, the metal mesh anode 7 is connected to the positive pole of the high-voltage pulse generator 4, and the needle-shaped cathode 8 is connected with the negative pole of high voltage pulse generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com