Disinfection cabinet working process control method

A technology of working process and control method, which is applied in the direction of electrical program control, disinfection, program control in sequence/logic controller, etc., and can solve problems such as ozone leakage, increased power consumption of the whole machine, and uncontrollable ozone concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

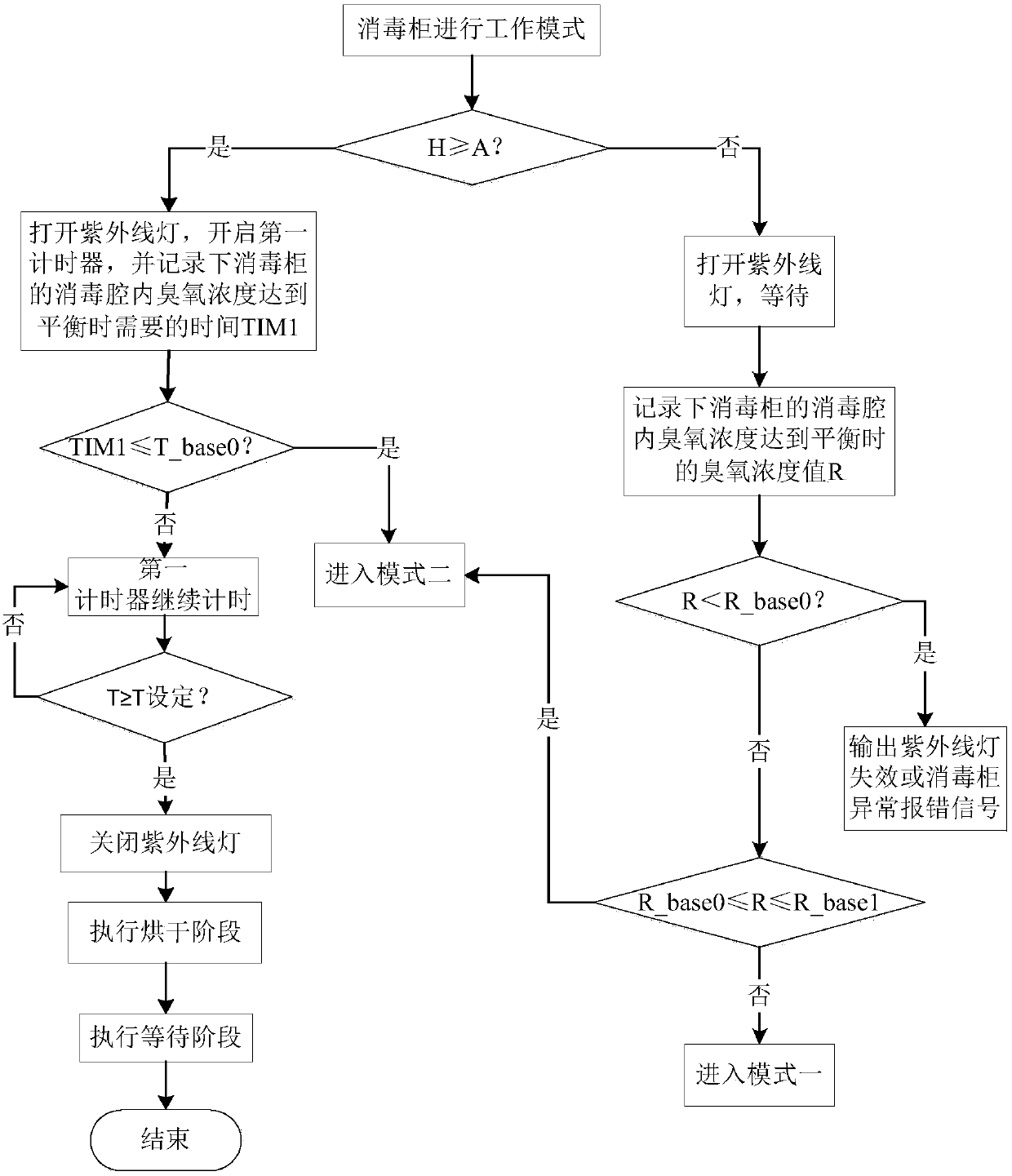

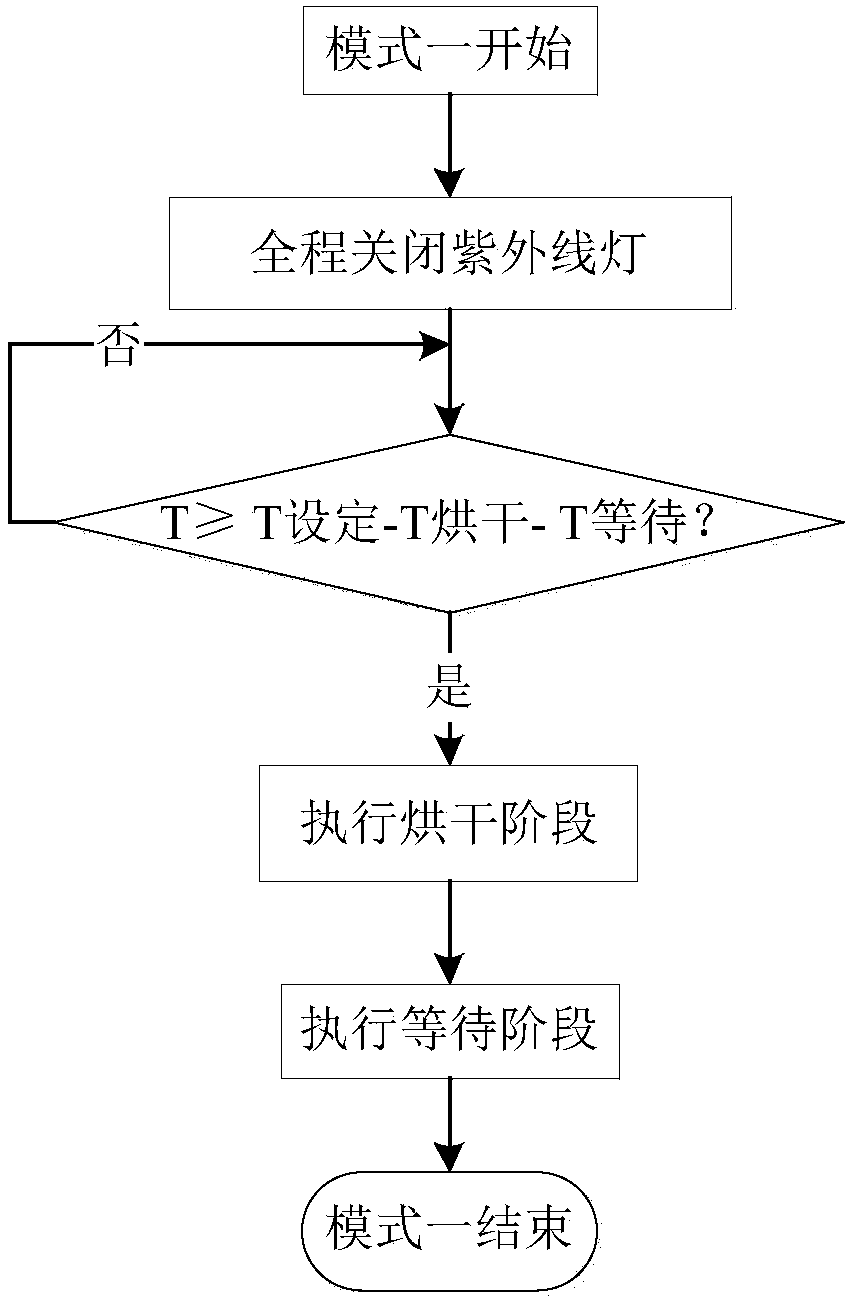

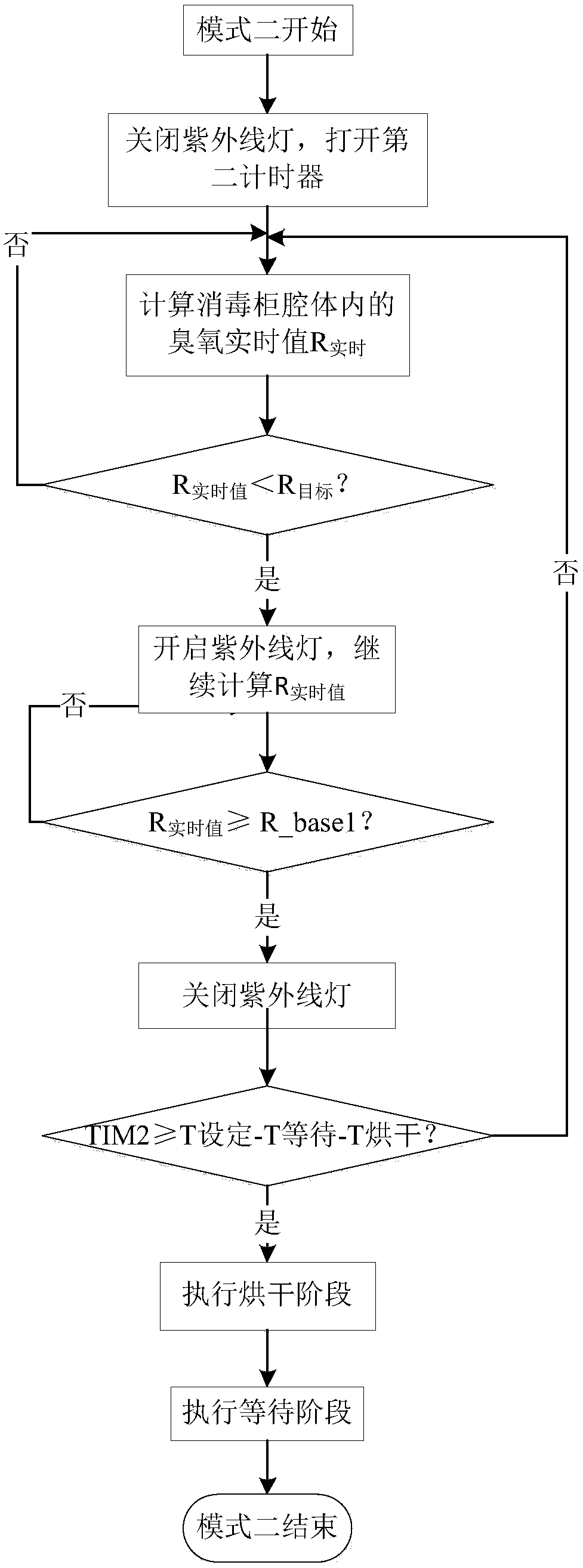

[0021] Such as figure 1 The shown disinfection cabinet working process control method is used to control the working process of the disinfection cabinet, which includes the following steps

[0022] Step 1. After the disinfection cabinet enters the working mode, collect the humidity value H in the cavity of the disinfection cabinet in real time, and judge the relationship between the humidity value H and the preset humidity value A. If H≥A, go to step 2. If H

[0023] Step 2, turn on the ultraviolet light, start the first timer, and record the time TIM1 required when the ozone concentration in the disinfection chamber of the disinfection cabinet reaches equilibrium. The ozone concentration is greater than the set threshold range;

[0024] Step 3. Determine the relationship between TIM1 and the preset value T_base0. When TIM1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com