Chopping machine

A shredder and machine head technology, which is applied in the direction of grain processing, etc., can solve the problems of complex internal structure, difficult processing and manufacturing, inconvenient maintenance and other problems of the S-knife shredder, so as to achieve simple structure, ensure the safety of use, and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical means and functions adopted by this application to achieve the predetermined purpose, the specific implementation, structure, features and functions according to this application will be described in detail below in conjunction with the drawings and preferred embodiments. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

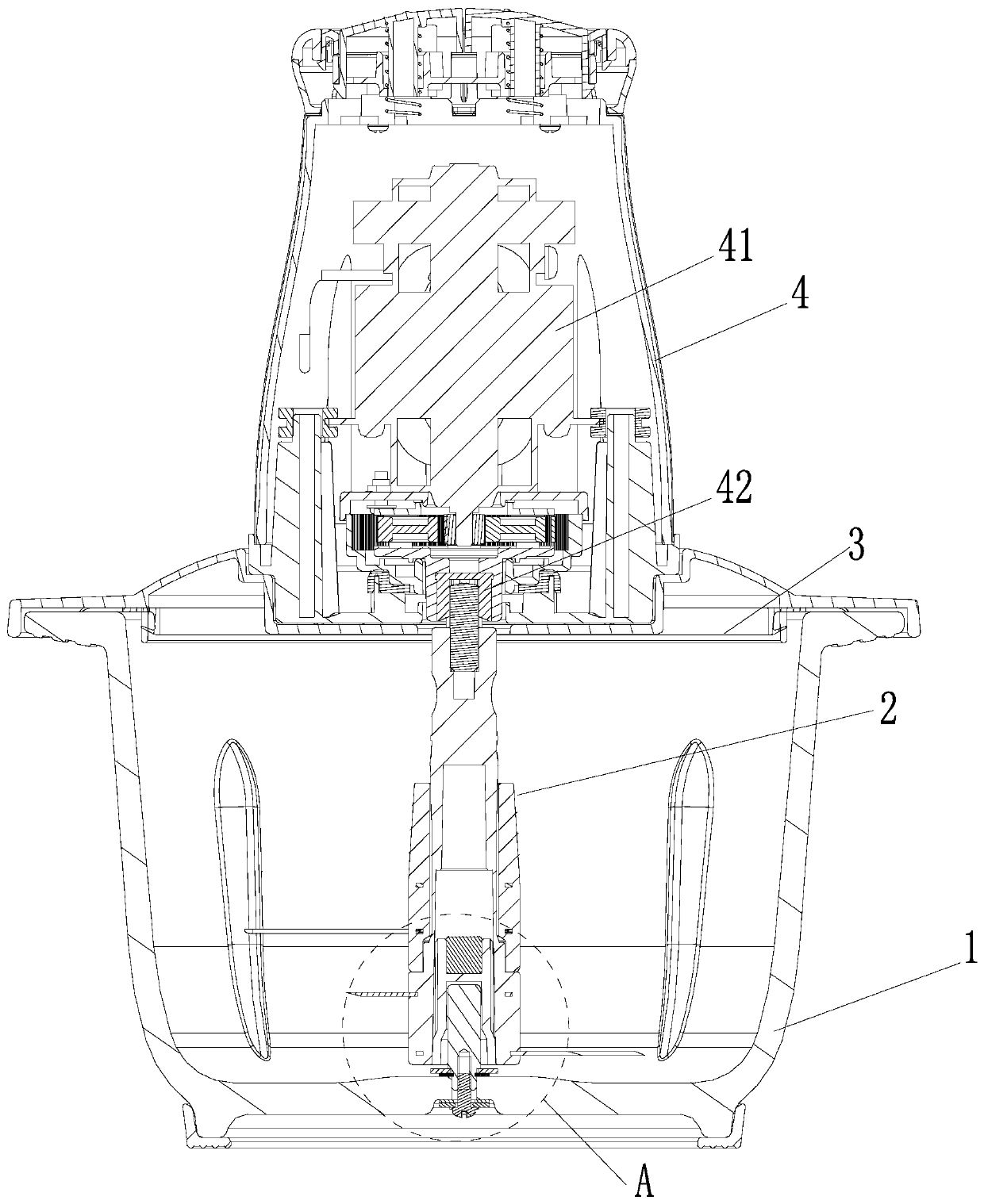

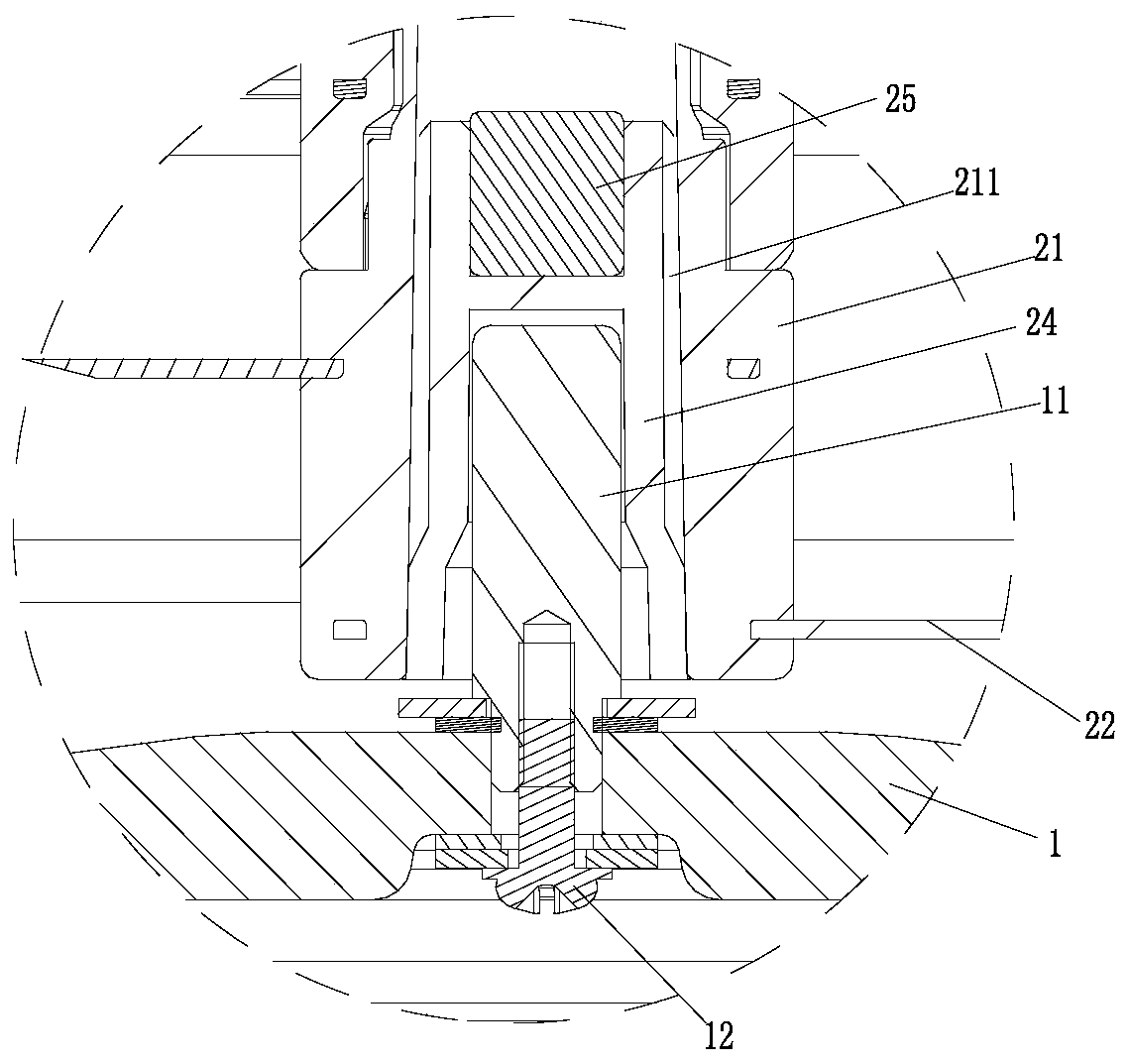

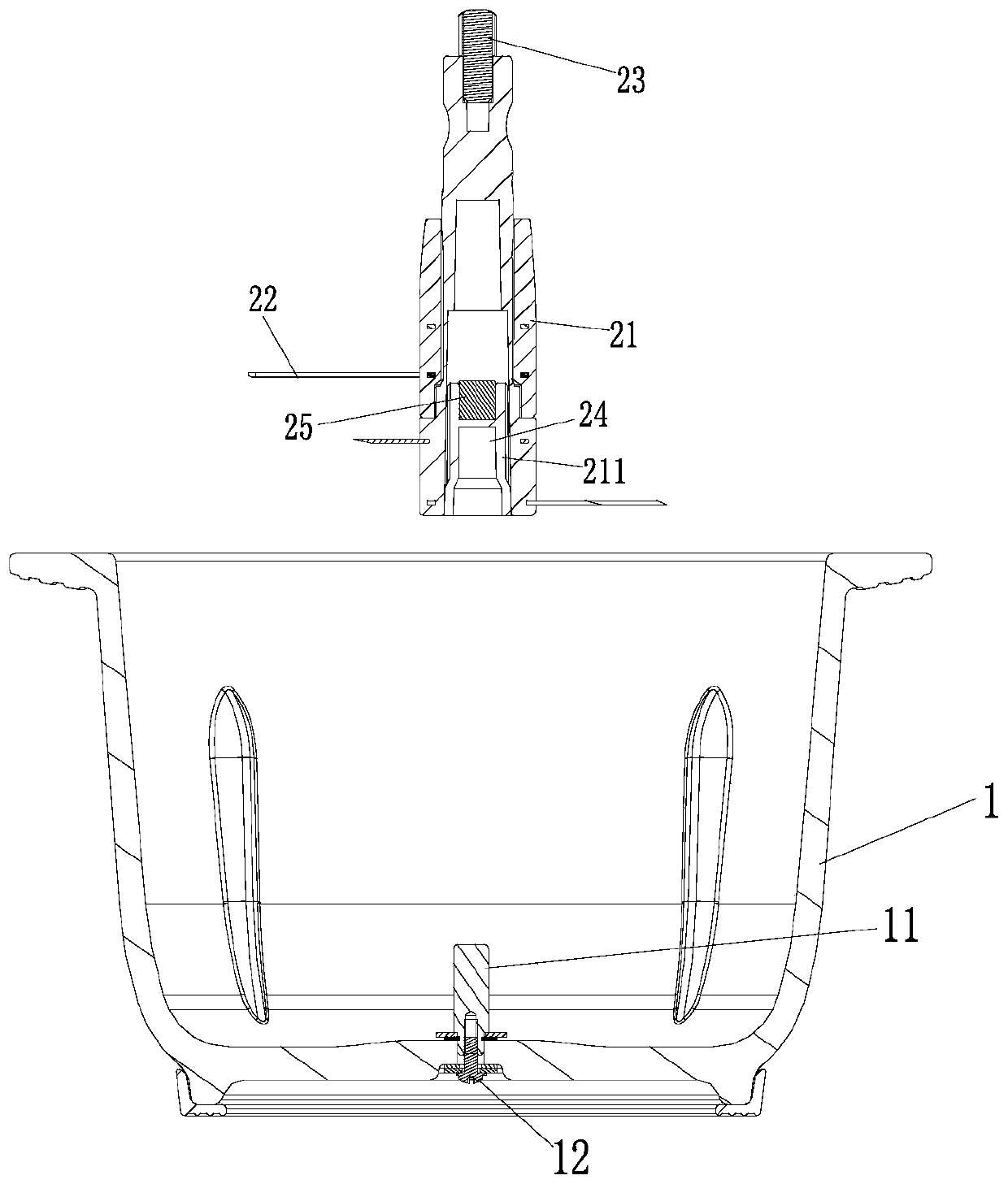

[0027] combine Figure 1-Figure 4 shown. The shredder in the prior art at least includes: a cup body 1 for providing a shredding processing space for food, the cup bottom of the cup body 1 is provided with a cup shaft 11, and the fixing element 12 passes through the cup body 1 from bottom to top The cup bottom fixes the cup shaft 11 on the cup bottom of the cup body 1; the knife assembly 2 detachably ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com