Blank and manufacturing technique for rolled plates

A technology of plate production and blank, applied in the field of blank and rolled plate production technology, can solve the problems of sawing process reversal, increase the internal stress of plate edge thickness, unsatisfactory roll edge effect, etc., to ensure normal progress and improve defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of this specific embodiment is to provide a blank, which can improve the defect of the concave dovetail at the edge of the plate without affecting the processing process of the rolled plate, and solve the current problem in this field.

[0023] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

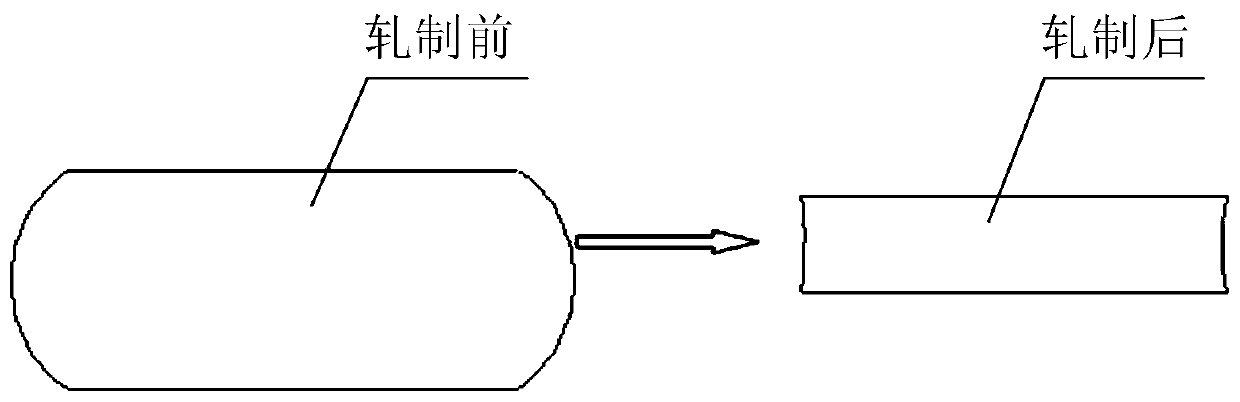

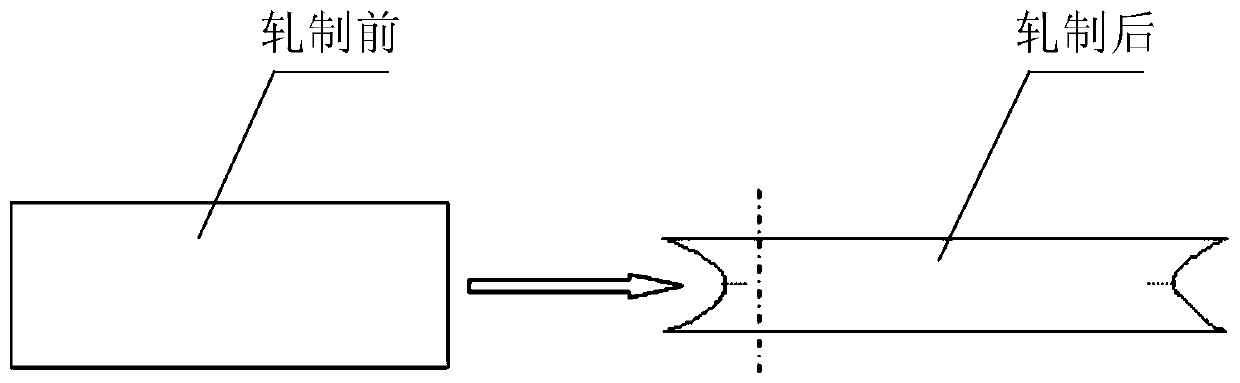

[0024] For the blank provided in this specific embodiment, please refer to Figure 1-2 ; Used for rolling plate, viewed from the side, the edge of the billet is a protruding arc in the middle. It can be seen from the above that the edge of the billet is convex in the middle; however, in the traditional rolling process, the billet with a flat edge will ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com