Highly-intelligent automatic discharging transverse stamping device

A technology of automatic unloading and punching device, applied in the field of punching device, can solve the problems of low machining accuracy and low work efficiency, and achieve the effects of improving efficiency, high degree of automation, and increasing frictional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

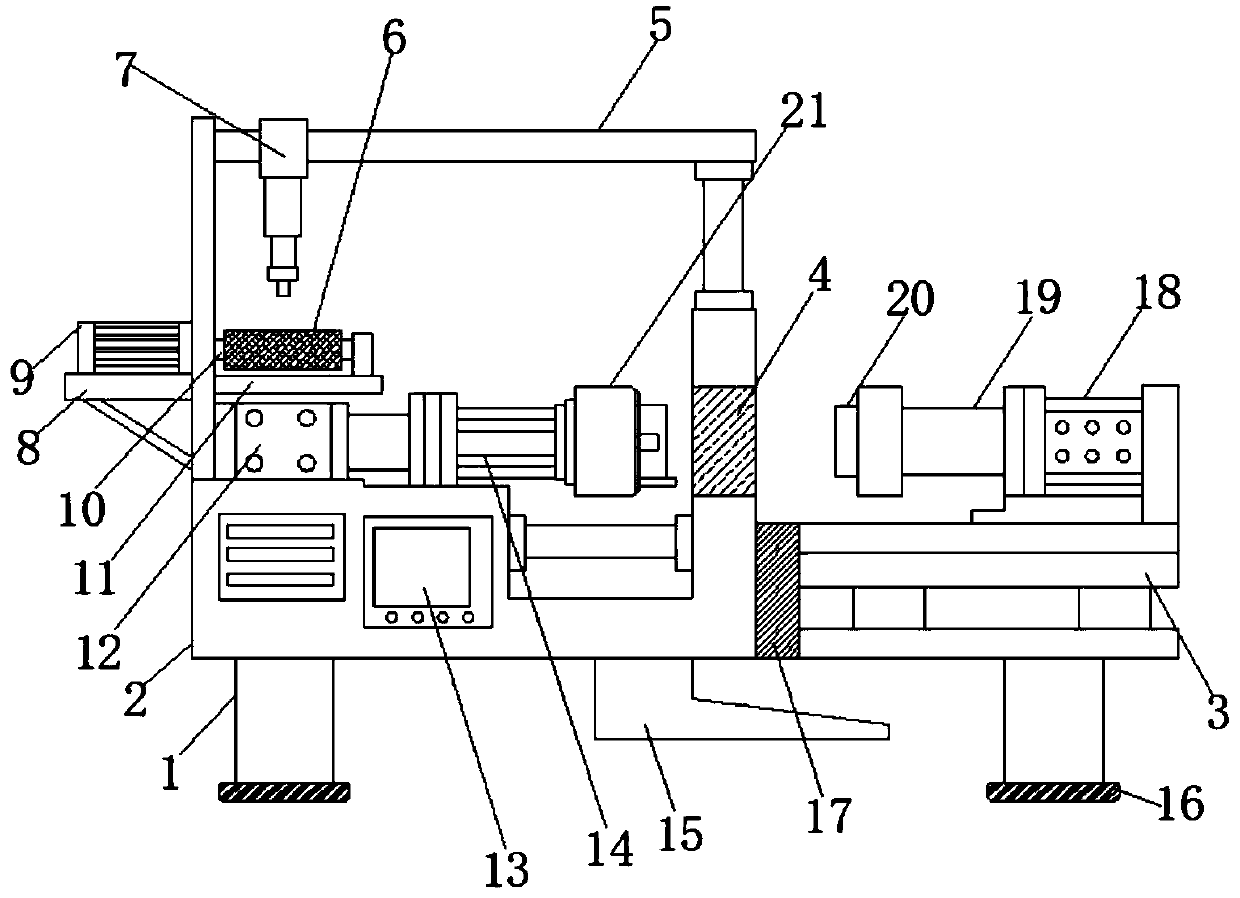

[0026] Embodiment 1, the bottom of the support foot 1 is provided with a silica gel pad 16, which plays a role of shock absorption and reinforcement, and the stability of the equipment is high. After the equipment is powered on, the servo motor drives the conveyor belt 6 to carry out batch transportation, which is transported by the previous process. Then, the whole process is controlled by the PLC controller 13, the model of the PLC controller 13 is S7-300, the slider 71 slides on the fixed rod 5, the lifting shaft 73 moves downward, and the product is clamped by the fetching claw 75, and then transported To the top of the load-bearing plate 212, after the lifting shaft 73 descends again, the product is placed on the load-bearing plate 212, and the retrieving claw 75 is released at the same time, the lifting shaft 73 slides upwards and recovers, and the material retrieving action of the product is completed.

Embodiment 2

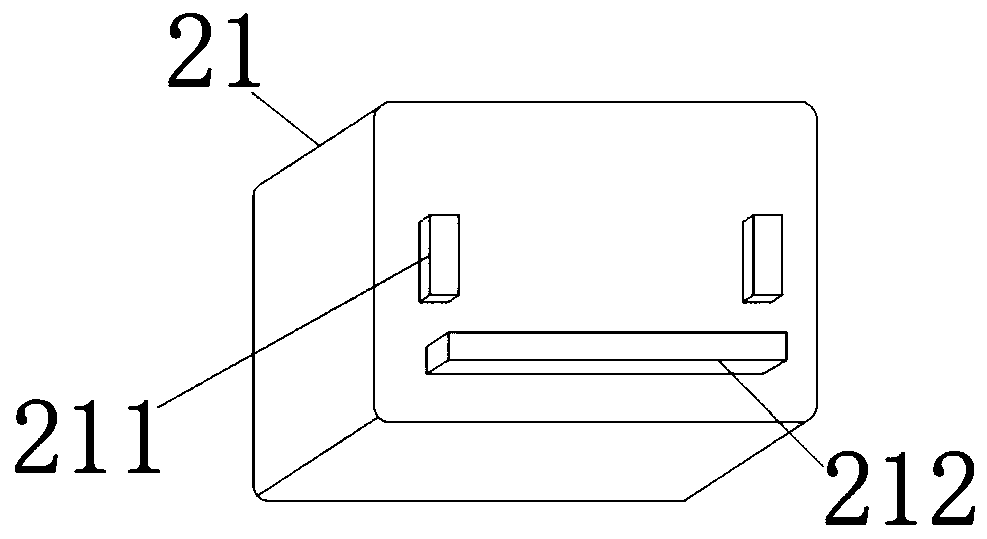

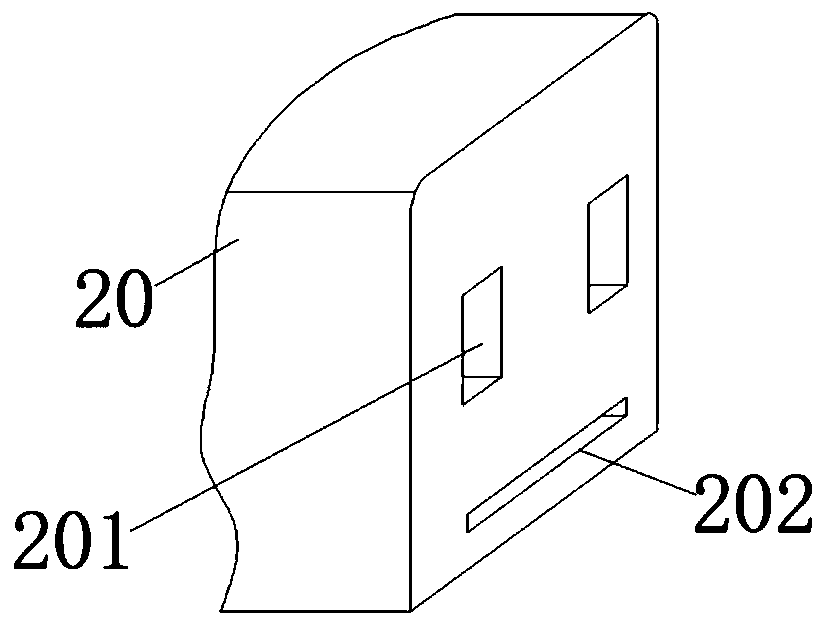

[0027] Embodiment 2, after the material retrieving is completed, the fixed gripper 211 clamps the product, the first cylinder 12 drives the first piston rod 14 to move to the right, passes through the inside of the stamping slot 4, and stops after reaching the processing station. The second cylinder 18 now drives the second piston rod 19 to move to the left, so that the punch 20 presses the product to stamp the product. During the stamping process, the fixed grippers 211 on both sides of the product go deep into the inside of the first groove 201, There is no collision between the mechanisms, and the load-bearing plate 212 snaps into the second groove 202 to simultaneously position the stamping, and the processing precision is high.

Embodiment 3

[0028] Embodiment 3: After the stamping is completed, the position of the punch 20 is restored, and the fixed gripper 211 is released. Since the product is deformed after stamping, the width of the bottom load-bearing plate 211 can no longer support the workpiece, and the workpiece automatically falls through the blanking chute. Hole 17 falls, is automatically slid down by unloading baffle plate 15 and carries out unloading, and reclaiming mechanism 7 actions carry out reclaiming next time afterwards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com