Four-axis planar robot integrated system for automatic loading and unloading of high-speed notching machines

An automatic loading and unloading and integrated system technology, applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., can solve problems such as monotonous machinery, harsh working environment, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

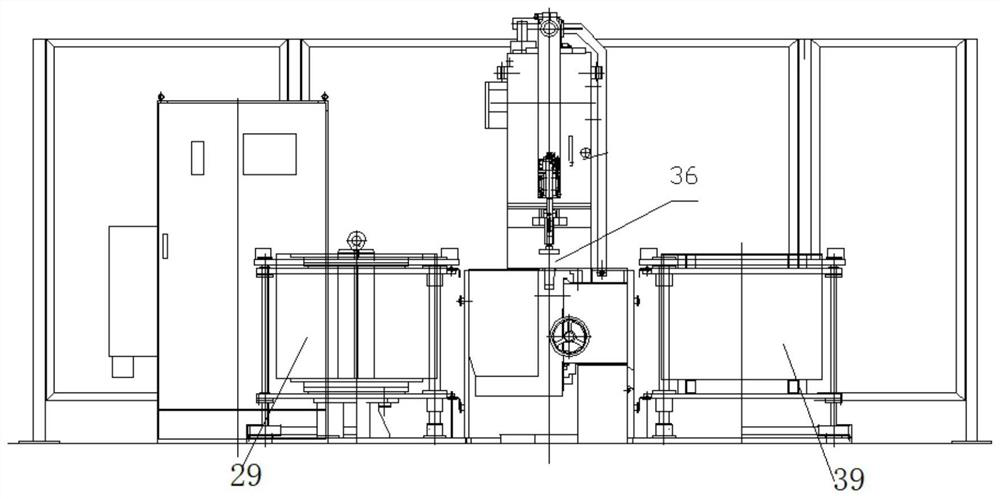

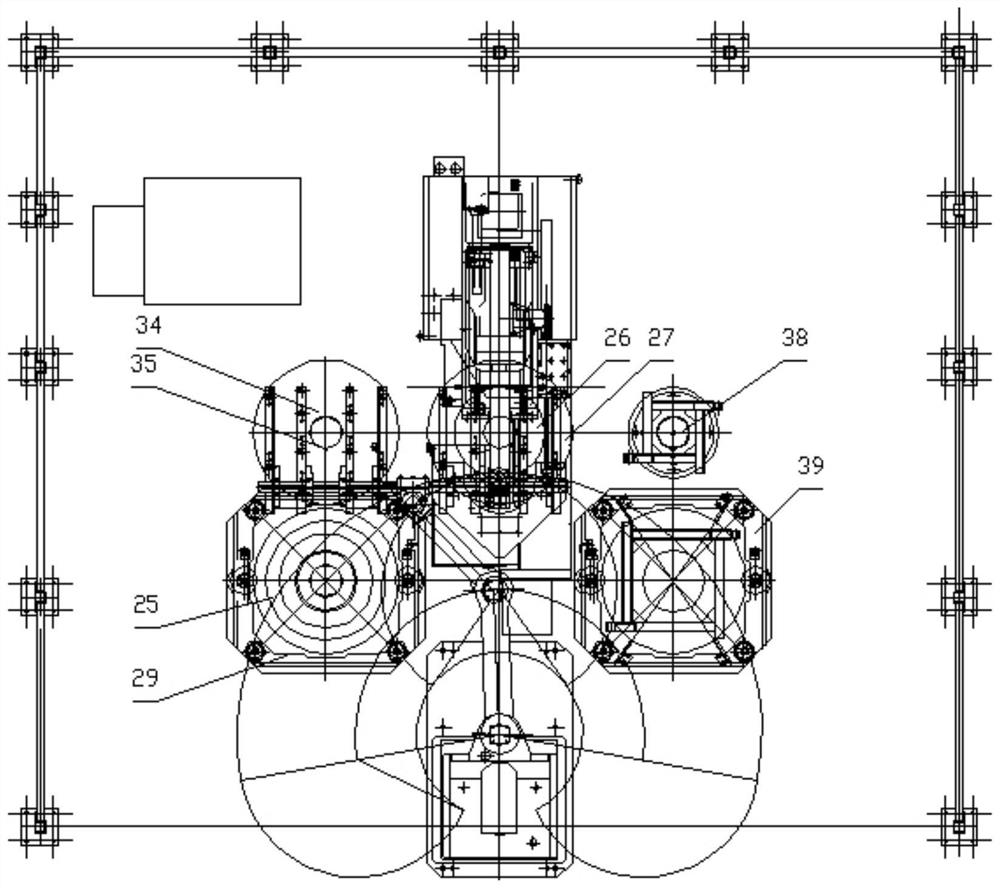

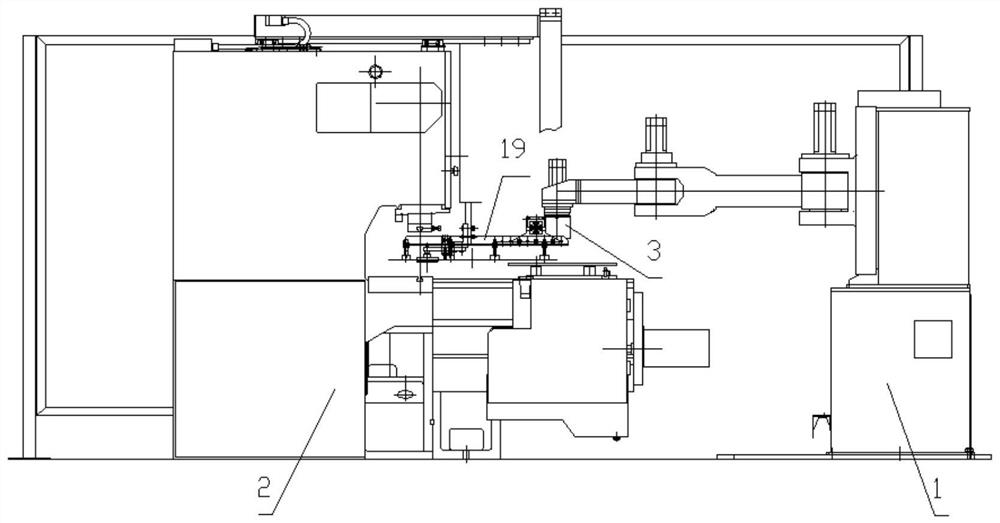

[0070] See attached picture.

[0071] A four-axis planar robot integrated system for automatic loading and unloading of high-speed notching machines includes a high-speed notching machine 2 and a four-axis planar robot 1 located in front of the high-speed notching machine.

[0072] The four-axis planar robot 1 includes a robot main body, the robot main body is provided with a longitudinal linear guide rail 17, and the linear guide rail 17 is slidably installed with a robot arm support seat; a longitudinal screw rod is installed on the robot main body, and the arm support seat suit On the screw mandrel and cooperate with the screw mandrel to form a screw nut mechanism 16; the arm support seat is equipped with a vertical three-axis controlled by a three-axis motor 11, and the robot arm 10 is fixed on the three axis, and the robot arm 10 is fixed on the arm support seat. The rear end is the robot shoulder 13, and the robot shoulder 13 is fixedly set on the three axes, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com