Mould for working lining of dry material tundish capable of reserving weir plate mounting groove

A dry material and installation groove technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of irregular groove shape, difficult groove, inaccurate groove position, etc., and achieve the solution of shape Irregularity, reduction of manpower, effect of regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

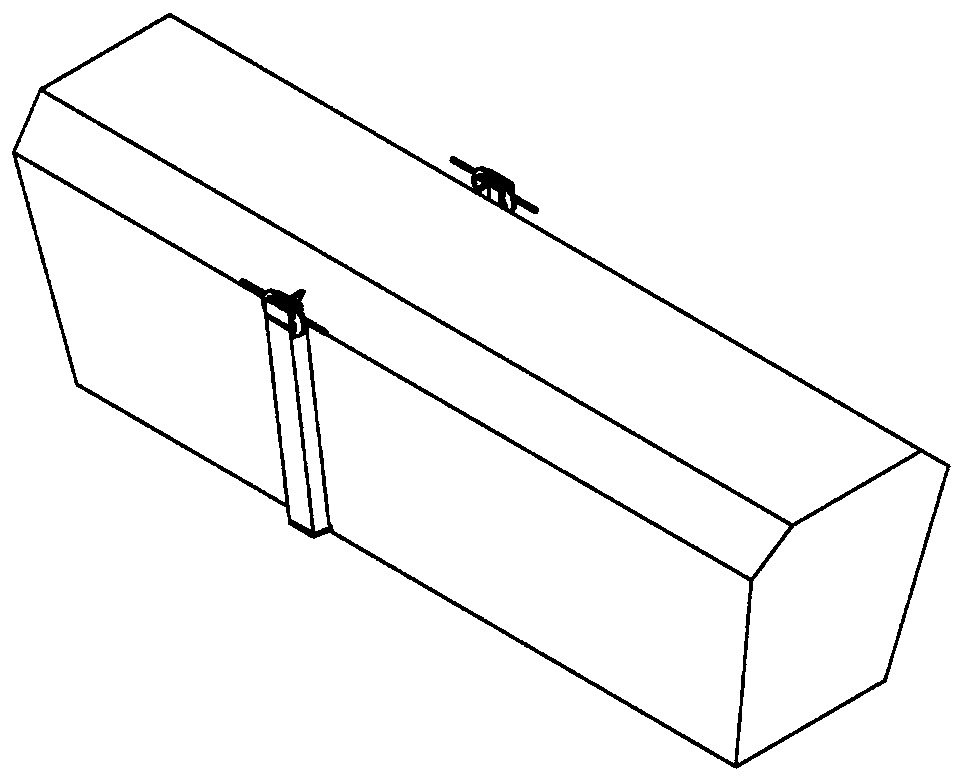

[0040] figure 1 Schematic diagram of the mold for the working lining of the dry material tundish that can reserve the weir plate installation slot, refer to figure 1 , The dry material tundish working lining mold includes: a dry material mold and two groove molds matched and installed with the dry material mold.

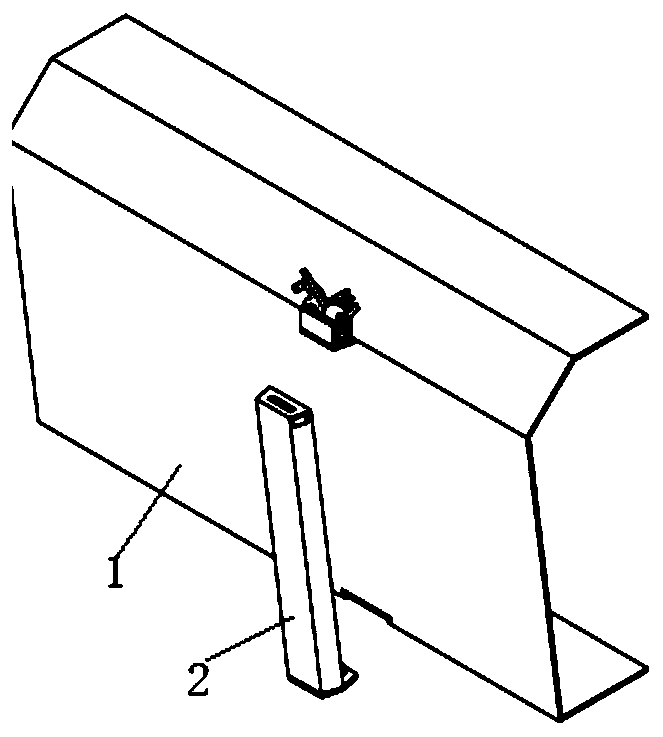

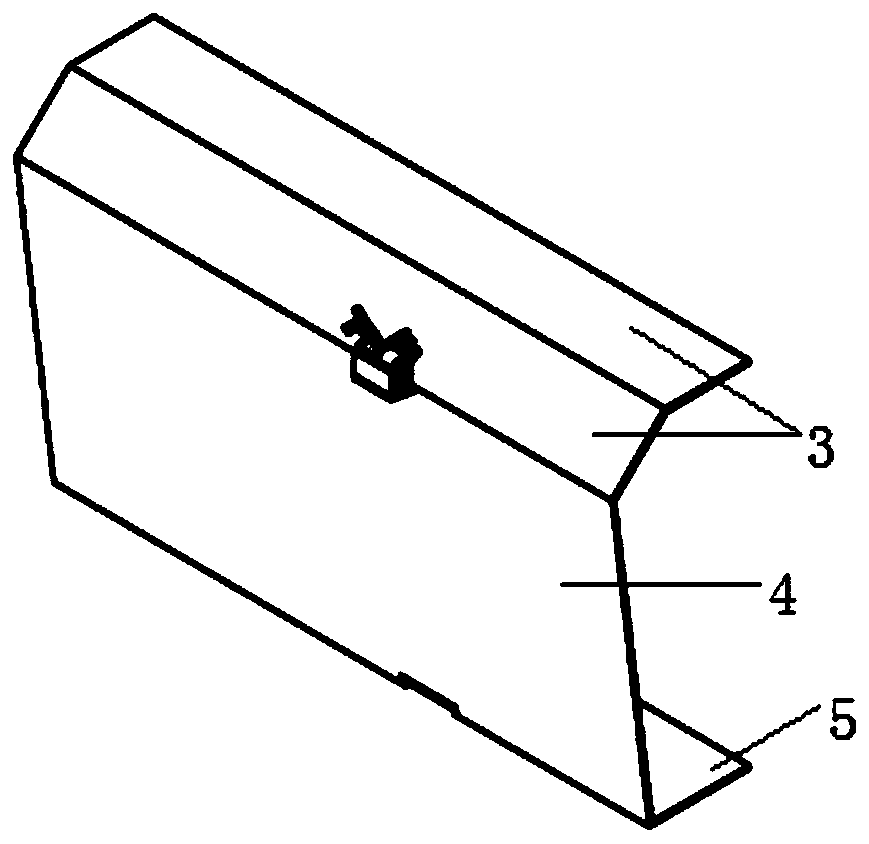

[0041] figure 2 It is a structural schematic diagram of a group of dry material molds and groove molds, refer to figure 2 , the dry material mold 1 and the groove mold 2 are placed separately. image 3 It is a schematic diagram of dry material mold, refer to image 3 , The dry material mold includes an upper base plate 3, a side plate 4 and a lower base plate 5, and the lower base plate 5 and the upper base plate 3 are arranged in the same direction.

[0042] Wherein, the length of the groove mold 2 is equal to the vertical height of the dry material mold 1, and the groove mold 2 and the dry material mold 1 are respectively provided with mutually cooperating fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com