A method for descaling pressure gel molds

A pressure gel and mold technology, which is applied in the field of transformers and insulating parts, can solve the problems of high cost, low efficiency of mold descaling, and impact on mold life, and achieves short cleaning time, shortened cleaning time, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

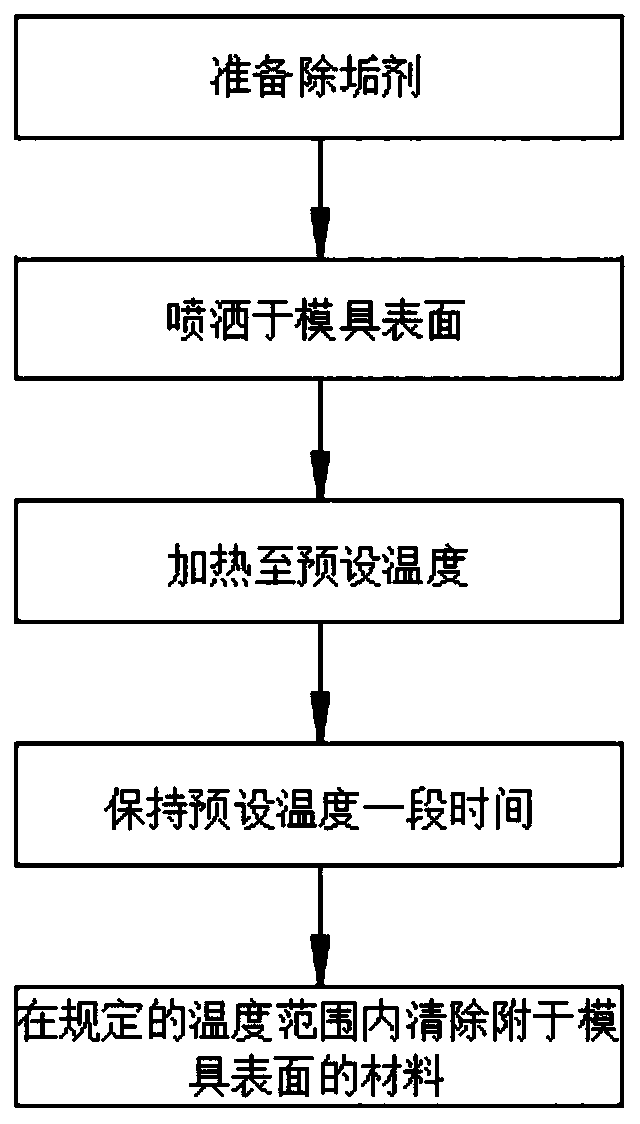

[0025] Such as figure 1 , prepare the descaling agent, mix N-methylpyrrolidone and triethylene glycol at a ratio of 5:1 and pour it into the watering can, use the watering can to spray the descaling agent on the surface of the mold to be cleaned by compressed air, the descaling agent should be Completely cover the material attached to the surface of the mold, close the feed port, heat the mold to the preset temperature of 130°C, and keep the preset temperature for 0.5 hours. At this time, the temperature of the heat preservation is the same as the preset temperature, which is convenient for operation. Let it stand until the temperature drops To 100 ℃ and above, open the mold, use a high-pressure air gun to clean most of the cured epoxy resin, and then wipe the surface of the mold with a cloth with strong hygroscopicity. mold agent.

Embodiment 2

[0027] Such as figure 1 , prepare the descaling agent, mix N-methylpyrrolidone and triethylene glycol at a ratio of 5:1 and pour it into the watering can, use the watering can to spray the descaling agent on the surface of the mold to be cleaned by compressed air, the descaling agent should be Completely cover the material attached to the surface of the mold, close the feed port, heat the mold to the preset temperature of 140°C, and keep the preset temperature for 0.5 hours. At this time, the temperature of the heat preservation is the same as the preset temperature, which is convenient for operation. Let it stand until the temperature drops to 100°C and above,

[0028] Open the mold, use a high-pressure air gun to clean most of the cured epoxy resin, and then wipe the surface of the mold with a cloth with strong hygroscopicity. The removal rate of dirt is 85%, and then re-apply the release agent.

Embodiment 3

[0030] Such as figure 1 , prepare the descaling agent, mix N-methylpyrrolidone and triethylene glycol at a ratio of 5:1 and pour it into the watering can, use the watering can to spray the descaling agent on the surface of the mold to be cleaned by compressed air, the descaling agent should be Completely cover the material attached to the surface of the mold, close the feed port, heat the mold to the preset temperature of 150°C, and keep the preset temperature for 0.5 hours. At this time, the temperature of the heat preservation is the same as the preset temperature, which is convenient for operation. Let it stand until the temperature drops To 100 ℃ and above, open the mold, use a high-pressure air gun to clean most of the cured epoxy resin, and then wipe the surface of the mold with a cloth with strong hygroscopicity. The removal rate of dirt can reach 90%. mold agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com