Adhering waterproof processing technology for plastic surfboard tail rudder groove

A processing technology and surfboard technology, which is applied in the field of plastic surfboard tail rudder groove bonding and waterproof processing technology, can solve the problem of weak connection between the tail rudder and the surfboard, and achieve the effect of improving the safety of use and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

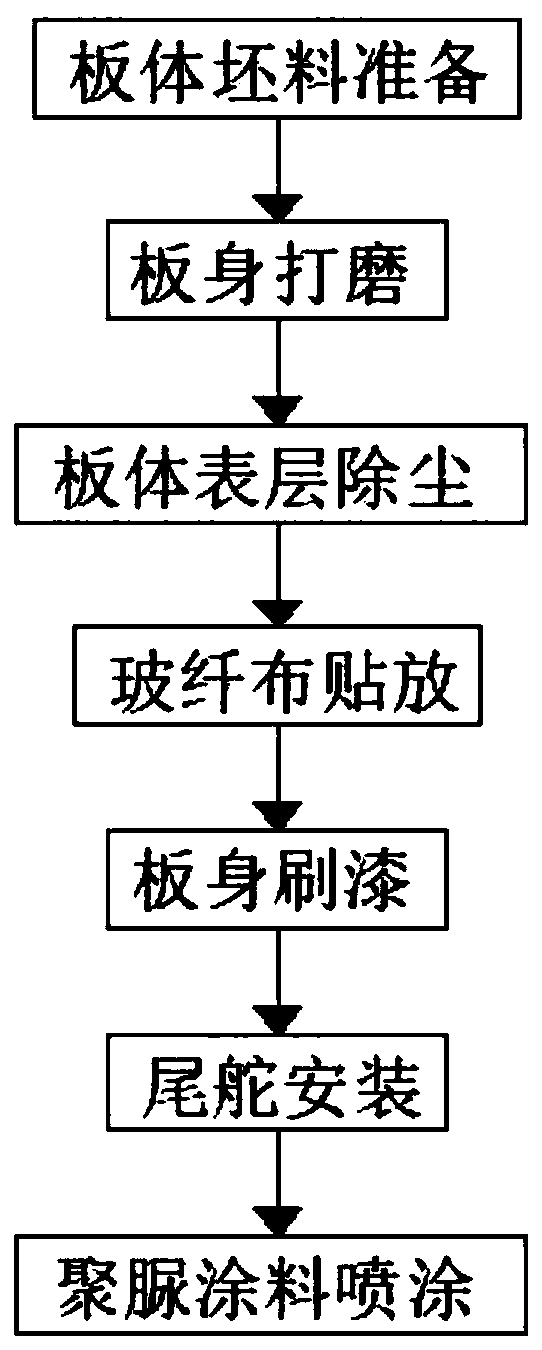

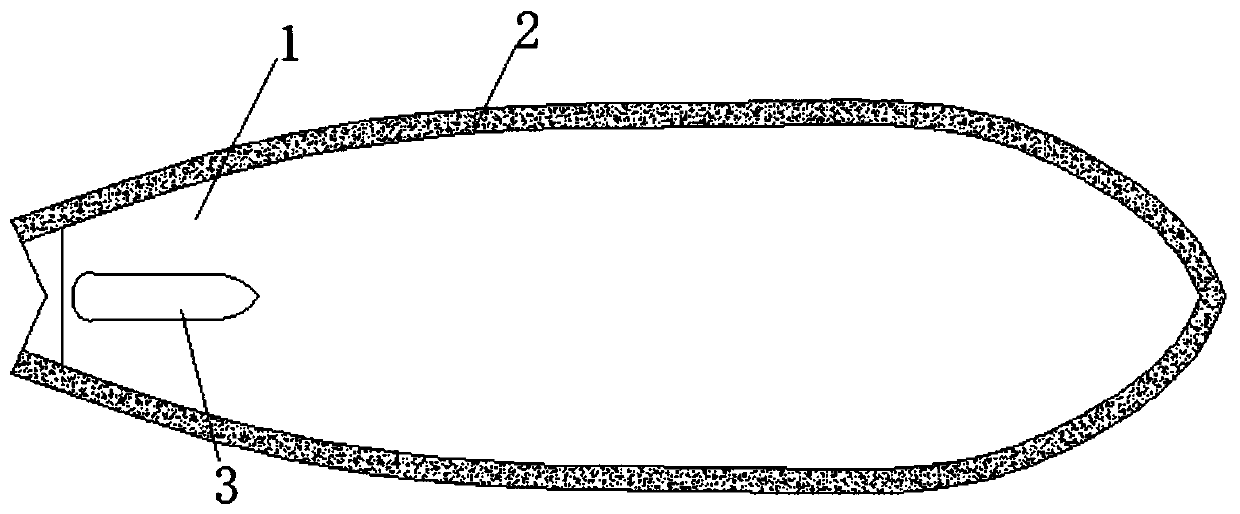

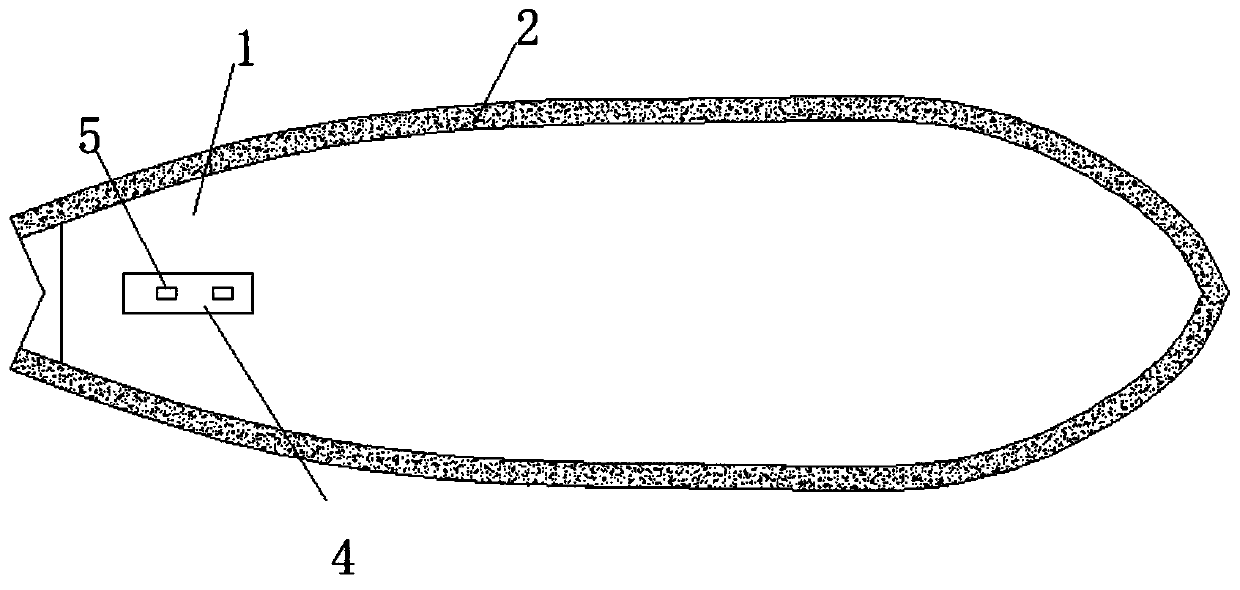

[0047] see Figure 1-6 , a plastic surfboard tail rudder groove bonding waterproof processing technology, comprising the following steps:

[0048] Step 1: Prepare the blank of the plate body, cut the foam body according to the design requirements, so that the length, width and thickness of the foam body are all shaped according to the required basic shape;

[0049] Step 2. Grinding the board body, manually grinding the basically formed board body, and grinding the board body according to the design standard size and shape, so that the board body surface is smooth and flat;

[0050] Step 3: Dedusting the surface of the board, use the adhesive roller to adhere and remove the dust on the polished board, and remove the dust adsorbed on the surface of the board during the grinding process;

[0051] Step 4: Lay the glass fiber cloth on the polished board, laying a layer of glass fiber cloth on it so that the size of the glass fiber cloth is the same as the board body, and use tools...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com