Castor oil-based double crosslinkable active resin monomer and preparation method thereof

A double-crosslinking, castor oil-based technology, which is applied in the field of castor oil-based double-crosslinking active resin monomers and its preparation, can solve the problems of high content of toxic components, complex formula, high volatility, etc., to improve comprehensive performance, The product preparation process is simple and the synthesis process is environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

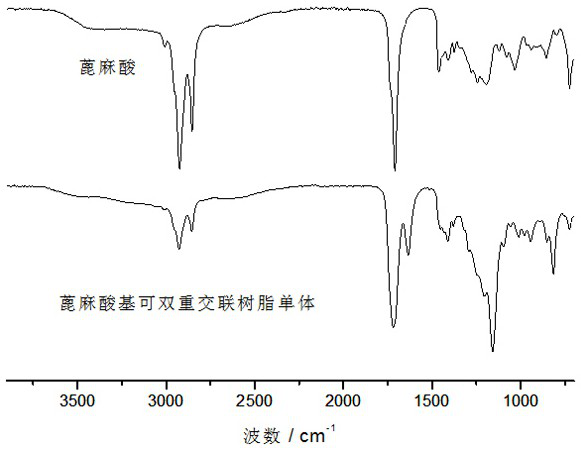

Image

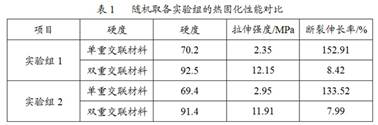

Examples

Embodiment 1

[0020] Add ricinoleic acid into the reaction container, then add epichlorohydrin according to the ratio of ricinoleic acid to epichlorohydrin molar ratio of 1:6, and then add 0.5% benzyl triethyl chloride of the total mass of the above reaction raw materials Ammonium, react at 115°C for 2 hours; cool down to 60°C, add calcium oxide and sodium hydroxide with the same molar number of carboxyl groups, and stir at 60°C for 3 hours; finally filter with suction and rotary evaporate to remove excess epichlorohydrin. Castor oil-based intermediate active monomer A; the prepared castor oil-based intermediate active monomer A and 0.5% N,N dimethylbenzylamine accounting for the total mass of the reactants are added to the reactor, and the temperature is raised to 60°C. Then dropwise add acrylic acid to it, the mol ratio of described acrylic acid and castor oil-based intermediate active monomer A is 1:1, after dropwise, 115 ℃ of reaction 2.5h, make castor oil-based intermediate active monom...

Embodiment 2

[0022] Ricinoleic acid is joined in the reaction vessel, then add epichlorohydrin according to the ratio of ricinoleic acid and epichlorohydrin mol ratio 1:9, then add the tetraethylammonium bromide of above-mentioned reaction raw material gross mass 1.5%, React at 120°C for 2 hours; cool down to 60°C, add calcium oxide and sodium hydroxide with an equal molar number of carboxyl groups, and stir for 3 hours at 60°C; finally, filter with suction and rotary evaporate to remove excess epichlorohydrin to obtain castor oil Base intermediate active monomer A; The castor oil base intermediate active monomer A that will make and the triphenylphosphine that accounts for 1.5% of reactant gross mass join in the reactor, be warming up to 80 ℃, to it dropwise then 2 -Ethylacrylic acid, the molar ratio of the 2-ethylacrylic acid to castor oil-based intermediate reactive monomer A is 1:1, after the dropwise addition, react at 120°C for 1.5h to prepare castor oil-based intermediate reactive mo...

Embodiment 3

[0024] Ricinoleic acid is joined in the reaction vessel, then add epichlorohydrin according to the ratio of ricinoleic acid and epichlorohydrin mol ratio 1:7, then add the tetramethylammonium bromide of above-mentioned reaction raw material gross mass 1.0%, React at 117.5°C for 2 hours; cool down to 60°C, add calcium oxide and sodium hydroxide with the same molar number of carboxyl groups, and stir for 3 hours at 60°C; finally, filter with suction and rotary evaporate to remove excess epichlorohydrin to obtain castor oil Base intermediate active monomer A; The castor oil base intermediate active monomer A that will make and account for 1.0% of reactant gross mass N, N dimethylbenzylamine joins in the reactor, is warming up to 70 ℃, then to Add methacrylic acid dropwise, the molar ratio of methacrylic acid to castor oil-based intermediate active monomer A is 1:1, after the dropwise addition, react at 118°C for 2.0h to obtain castor oil-based intermediate active monomer B ; Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com