Insulation pipes for heavy oil well hot water closed circulation heating viscosity reducing equipment

A closed-loop, heat-insulating pipe technology, used in isolation devices, wellbore/well components, earth-moving drilling, etc., can solve the problems of high use cost, poor heating effect, poor heating effect, etc., and achieve low use cost, Not easy to be damaged, easy to go down the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

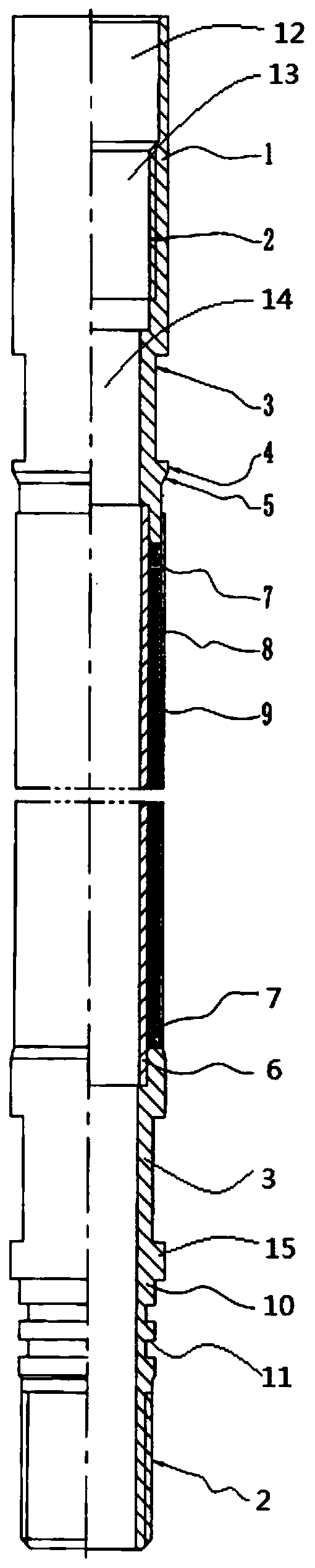

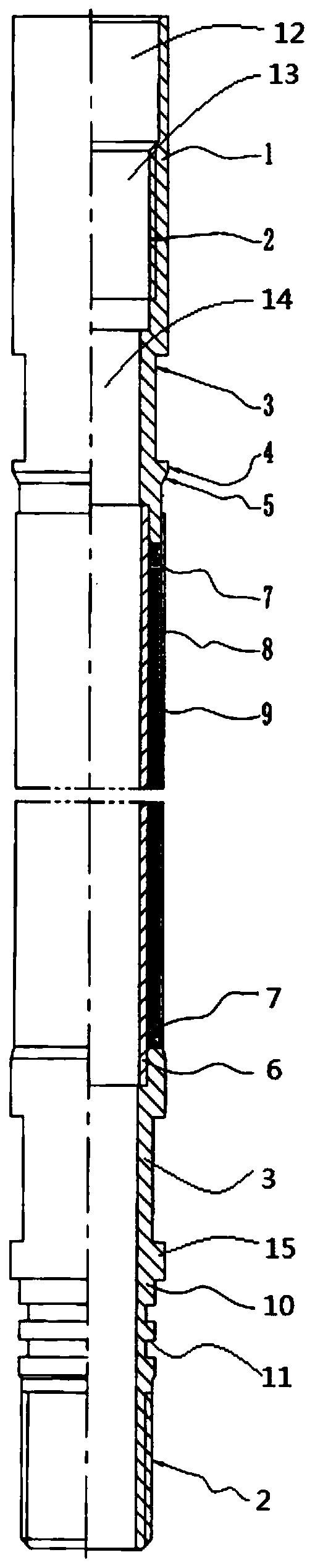

[0027] Such as figure 1 As shown, this embodiment provides a thermal insulation pipe for a heavy oil well hot water closed circulation heating viscosity reduction device, including an upper joint 1, a pipe body assembly and a lower joint 10, and the upper joint 1 and the lower joint 10 are respectively arranged on the pipe body assembly Both ends are connected with the pipe body assembly. When in use, any two adjacent heavy oil well hot water closed circulation heating viscosity reduction devices use insulation pipes, and one of the heavy oil well hot water closed circulation heating viscosity reduction devices uses insulation pipes. The upper joint 1 of the pipe can be threadedly connected with the lower joint 10 of the thermal insulation pipe for the hot water closed circulation heating viscosity reduction device of another heavy oil well, and the thermal insulation pipe for any two adjacent heavy oil well hot water closed circulation heating viscosity reduction devices The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com