Anti-low-temperature boiler system

A low-temperature prevention and boiler technology, applied in preheating, supplementary feed water, steam generation, etc., can solve problems that threaten the safe operation of gas-fired hot water boilers, corrosion of tube plates, smoke pipes and chimneys, and low return water temperature of hot water boilers, etc. To achieve the effect of ensuring the normal design life, avoiding corrosion and preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

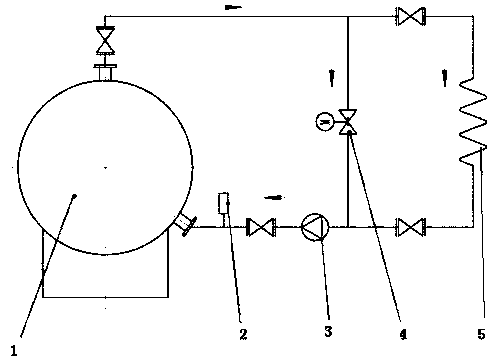

[0008] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0009] In the technical solution of the present invention, the peripheral part of the boiler includes the outlet pipe of the boiler, the inlet pipe and the bypass pipe connected between the outlet pipe and the inlet pipe, and a temperature sensor 2 is arranged at the return water inlet of the boiler 1, and the temperature sensor 2 is mainly used to detect the return water temperature, the temperature detected by the temperature sensor 2 will be fed back to the controller, and the controller can control the opening and closing of the electric induction valve 4 according to the set temperature. If the water dew point in the flue gas is known to be 56-60°C according to the partial pressure coefficient of water vapor, then the return water temperature should be controlled above 60°C to prevent condensation o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap