System-level packaging structure with internal heat dissipation device

A technology of system-level packaging and heat dissipation device, which is applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of ineffective heat dissipation, limited reduction of thermal resistance, etc., to reduce stress and reduce thermal resistance , Improve the effect of heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

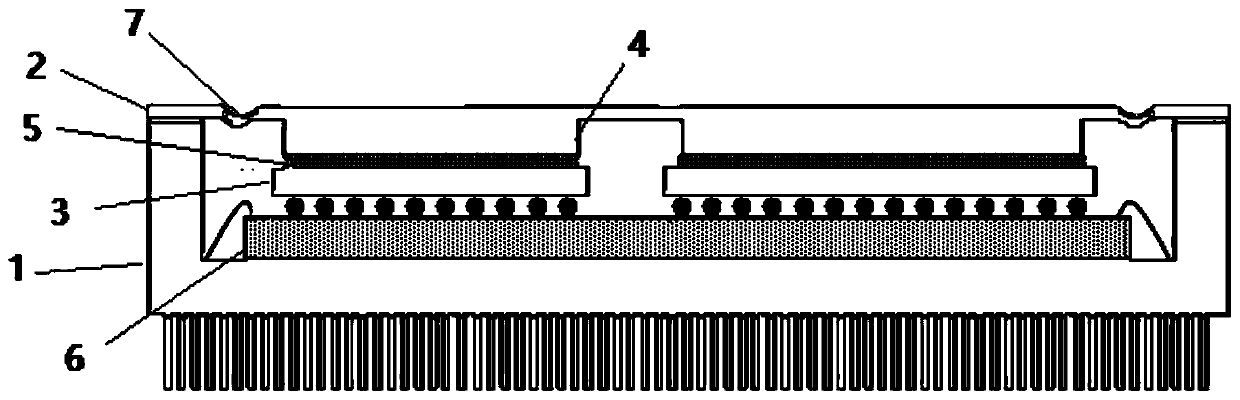

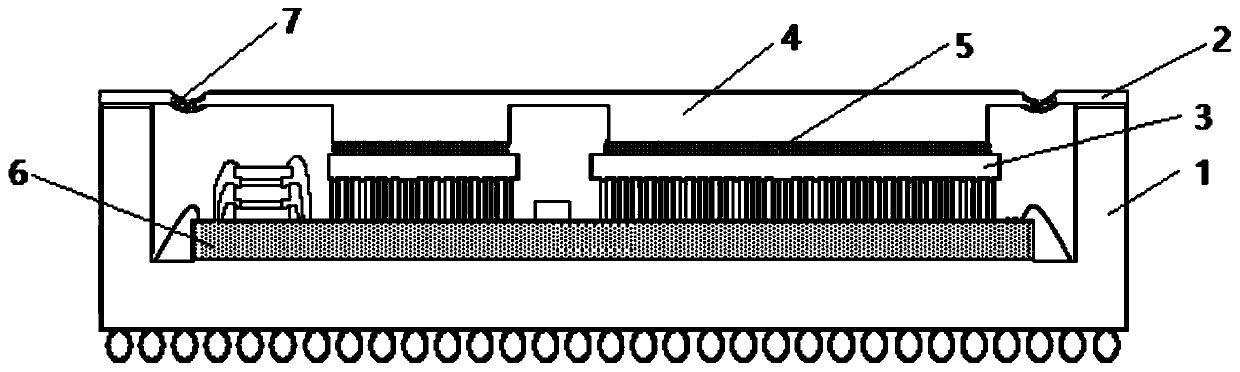

[0024] see figure 2 , the shell of the present invention adopts ceramic packaging, the substrate 6 is bonded to the bottom of the inner cavity of the shell 1, and the chip 3 with large power consumption is welded on the substrate 6 after planting pillars. There are other laminated chips, resistors, capacitors, magnetic beads and other components. A thermal interface coating 5 is used to assemble a heat sink 4 on the chip 3, and the heat sink 4 and the cover plate 2 are made of the same material. A stress bend is designed at the place where the cover plate 2 is close to the Kovar frame to reduce the influence of stress caused by position mismatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com