An ip67-compliant aluminum alloy battery tray for electric vehicles

A technology for battery trays and electric vehicles, which is applied to battery pack components, isolation of batteries from their environment, circuits, etc., can solve the problems of long-term popularization, unfavorable strength, and waterproof guarantee, and achieve the effect of ensuring strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

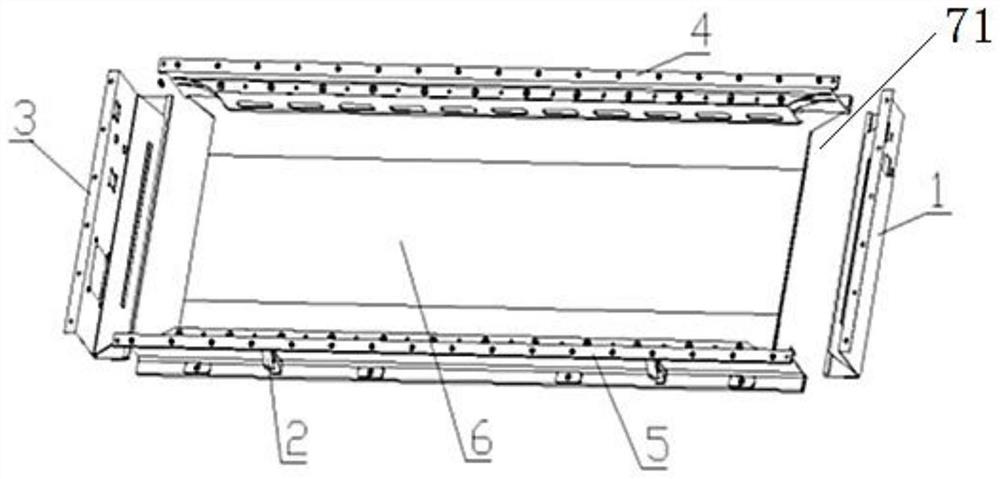

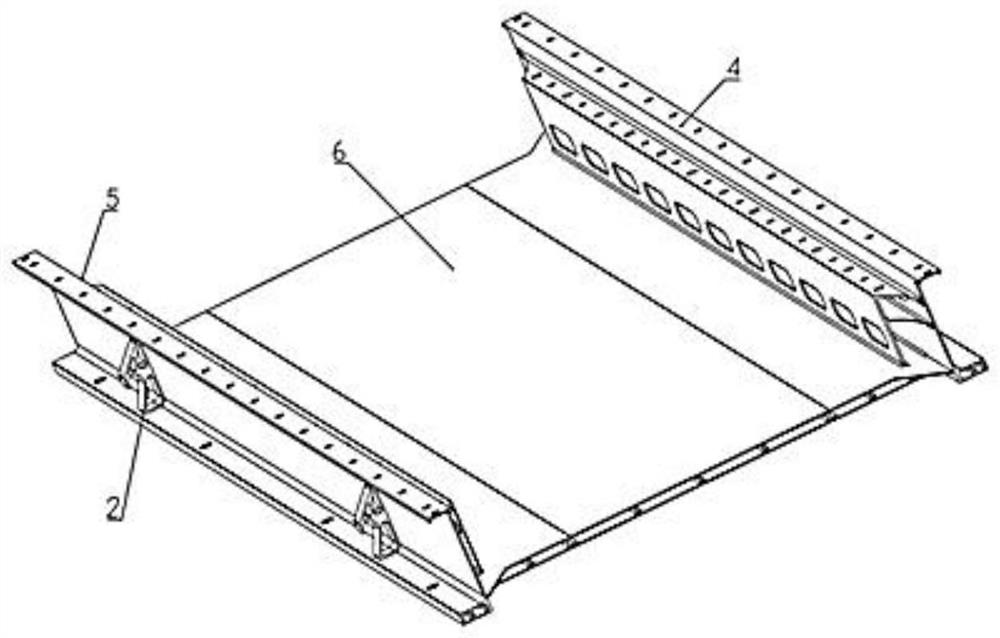

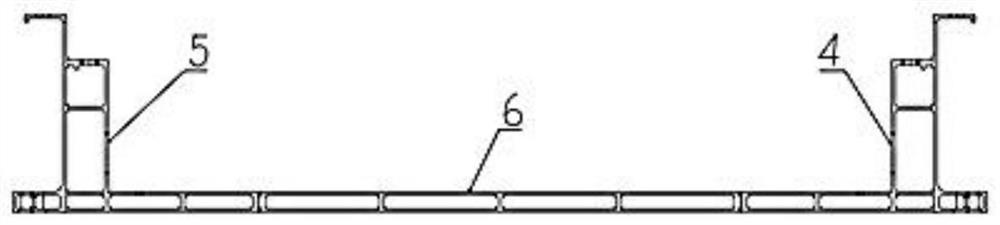

[0045] see figure 1 as well as Figure 5 , an electric vehicle aluminum alloy battery tray conforming to IP67, including an aluminum alloy battery tray, the aluminum alloy battery tray includes a U-shaped chassis and left beams 3 and right beams 1 arranged on the left and right sides of the U-shaped chassis, U-shaped The bottom frame includes a support part arranged horizontally, and the support part includes an upper aluminum alloy plate and a lower aluminum alloy plate arranged up and down, and a connecting bar sandwiched between the aluminum alloy plates; mirror images are provided at the left and right ends of the upper aluminum alloy plate Symmetrically arranged isosceles trapezoidal notch 71; the left and right ends of the lower aluminum alloy plate are provided with mirror-symmetrically arranged rectangular notches; both the left beam 3 and the right beam 1 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com