A high-performance porous carbon-tin oxide monodisperse composite ball negative electrode material and its preparation method and application

A technology of tin oxide single and negative electrode materials, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of difficult structure and large polarization, and achieve the effect of improving electrical conductivity, reducing polarization, and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

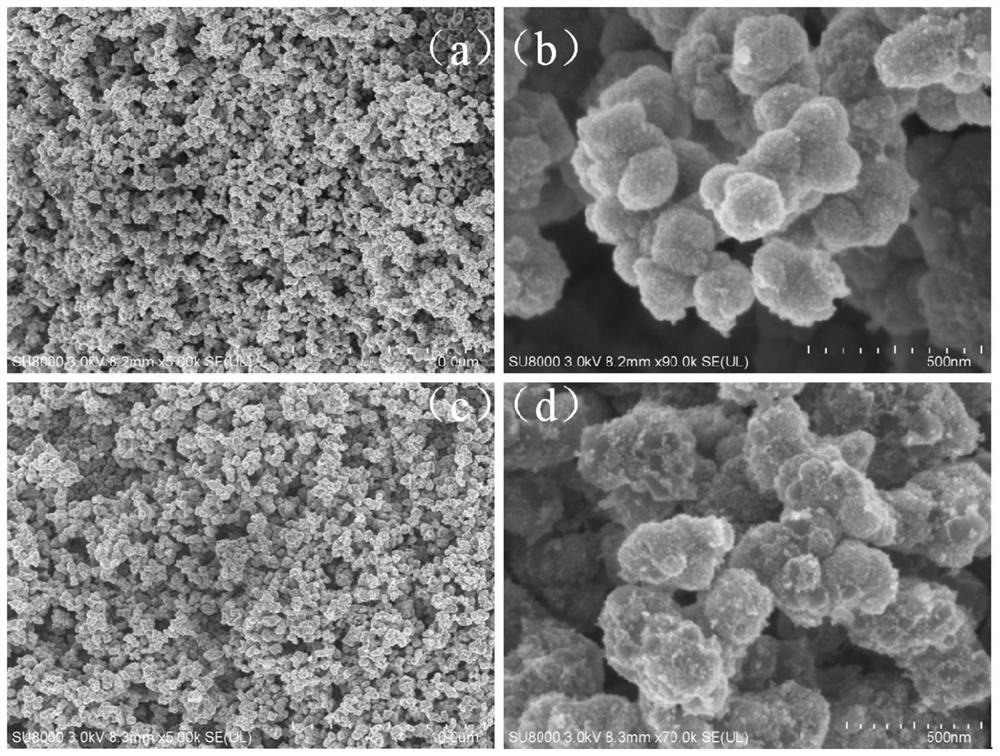

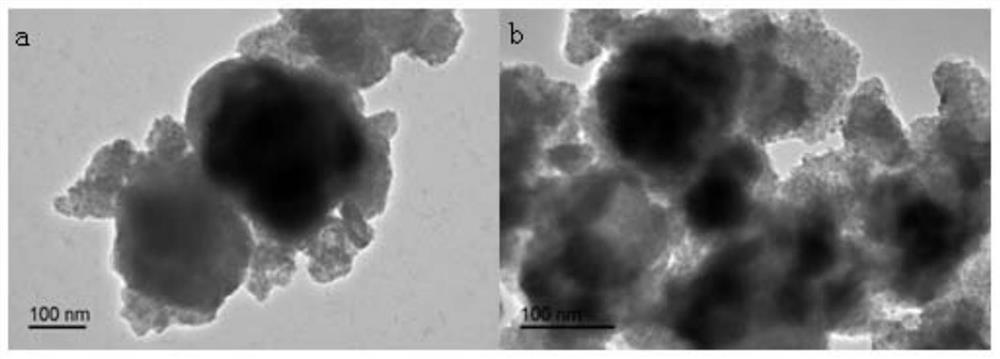

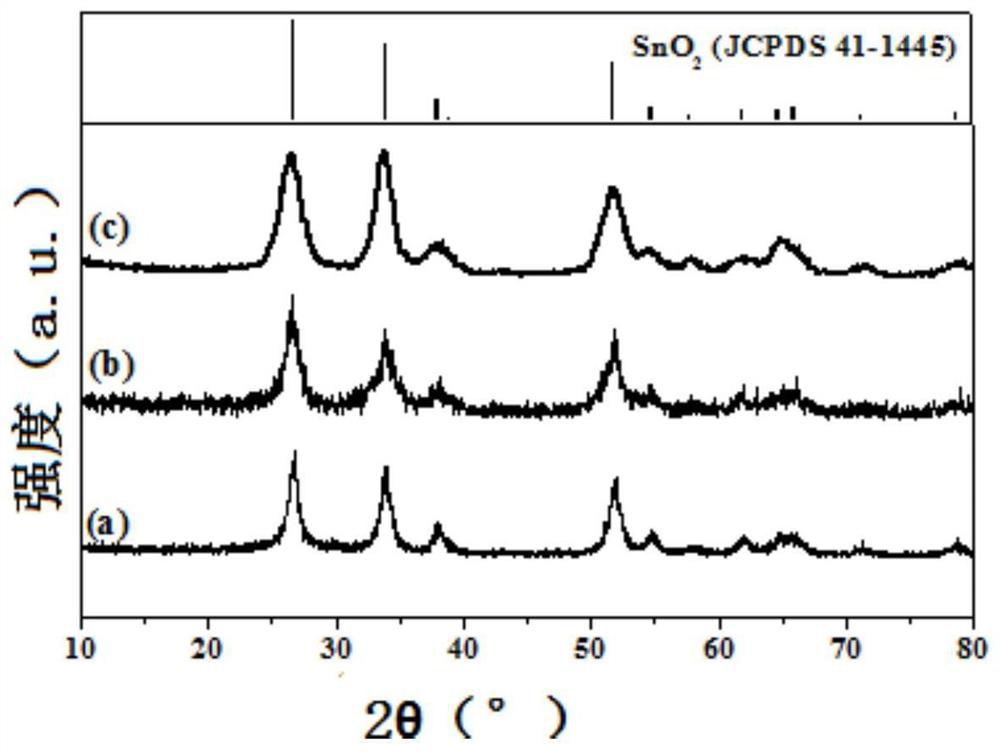

[0033] Disperse 0.1 mL of pyrrole in 100 mL of deionized water, stir ultrasonically to disperse evenly (no oil droplets), add 0.2 g of P123 and 2 nm monodisperse SiO 2 1 g of the gel was dispersed by ultrasonic stirring until it was completely dissolved; in the above mixed aqueous solution, add 0.5 g of SnCl 2 , ultrasonically stirred for 15 min; then magnetically stirred in an ice bath for 20 min. Ultrasonic dispersion, stirring evenly; another preparation containing 0.5 g ammonium persulfate aqueous solution 10 mL, pour it into the above solution, ice bath for 12 h. After the reaction, filter with suction, wash with deionized water for 3 to 5 times, and vacuum dry at 70°C for 3 to 5 hours to prepare the precursor monodisperse composite balls. The obtained composite was heat-treated at 500 °C for 12 h under Ar atmosphere. High-performance porous carbon-tin oxide monodisperse composite spheres were prepared by treating with 30% HF acid aqueous solution for 0.5 h.

[0034] A...

Embodiment 2

[0036] Disperse 0.2 mL of pyrrole in 100 mL of deionized water, disperse evenly (without oil droplets) under ultrasonic stirring, add 0.5 g of P123 and 5 nm monodisperse SiO 2 2 g of the gel was dispersed with ultrasonic stirring until it was completely dissolved; in the above mixed aqueous solution, 0.5 g of SnCl was added 2 , ultrasonically stirred for 15 min; then magnetically stirred in an ice bath for 20 min. Ultrasonic dispersion, stirring evenly; another preparation containing 0.8 g ammonium persulfate aqueous solution 10 mL, pour it into the above solution, ice bath for 12 h. After the reaction, filter with suction, wash with deionized water for 3 to 5 times, and vacuum dry at 70°C for 3 to 5 hours to prepare the precursor monodisperse composite balls. The obtained composite was heat-treated at 550 °C for 6 h under Ar atmosphere. High-performance porous carbon-tin oxide monodisperse composite spheres were prepared by treating with 10% HF acid aqueous solution for 24 ...

Embodiment 3

[0039] Disperse 0.2 mL of pyrrole in 100 mL of deionized water, disperse evenly (no oil droplets) under ultrasonic stirring, add 0.3 g of P123 and 10 nm monodisperse SiO 2 10 g of the gel was dispersed by ultrasonic stirring until it was completely dissolved; in the above mixed aqueous solution, 1 g of SnCl was added 2 , ultrasonically stirred for 15 min; then magnetically stirred in an ice bath for 20 min. Ultrasonic dispersion, stirring evenly; another preparation containing 0.8 g ammonium persulfate aqueous solution 10 mL, pour it into the above solution, ice bath for 12 h. After the reaction, filter with suction, wash with deionized water for 3 to 5 times, and vacuum dry at 70°C for 3 to 5 hours to prepare the precursor monodisperse composite balls. The obtained composite was heat-treated at 600 °C for 2 h under Ar atmosphere. High-performance porous carbon-tin oxide monodisperse composite spheres were prepared by treating with 20% HF acid aqueous solution for 6 h.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com