Carbon brush holder

A carbon brush, annular base technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of short circuit in the insulating layer, improve the commutation and current collecting performance, reduce looseness , reduce the effect of weakening sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

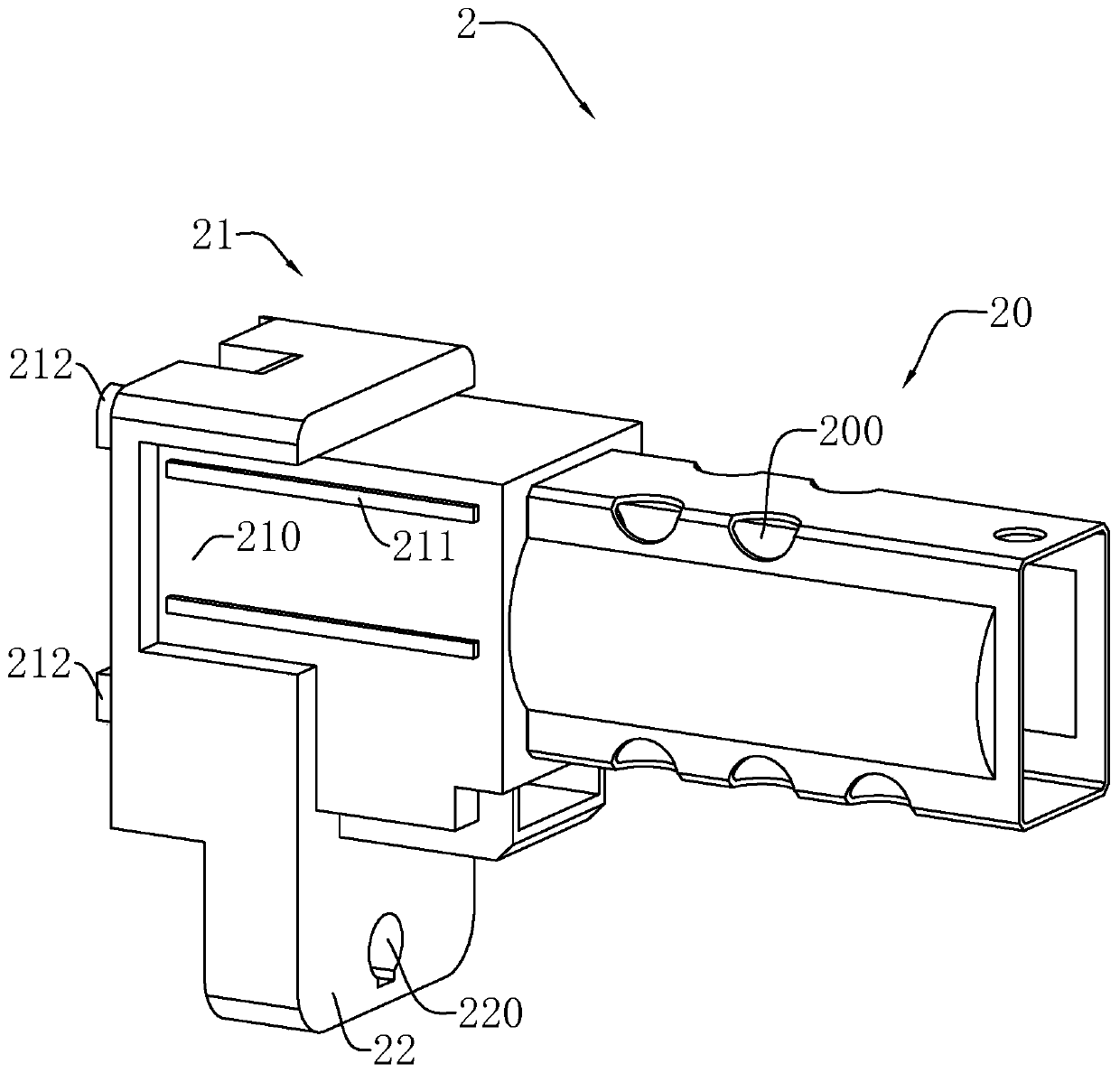

[0036] Examples, see figure 1 , a carbon brush with 3 brush holders, refer to figure 1 , including a casing 2, the casing 2 includes a conductive tube 20 and an insulating shell 21 integrally connected to the conductive tube 20, and the conductive tube 20 is provided with a ventilation hole 200.

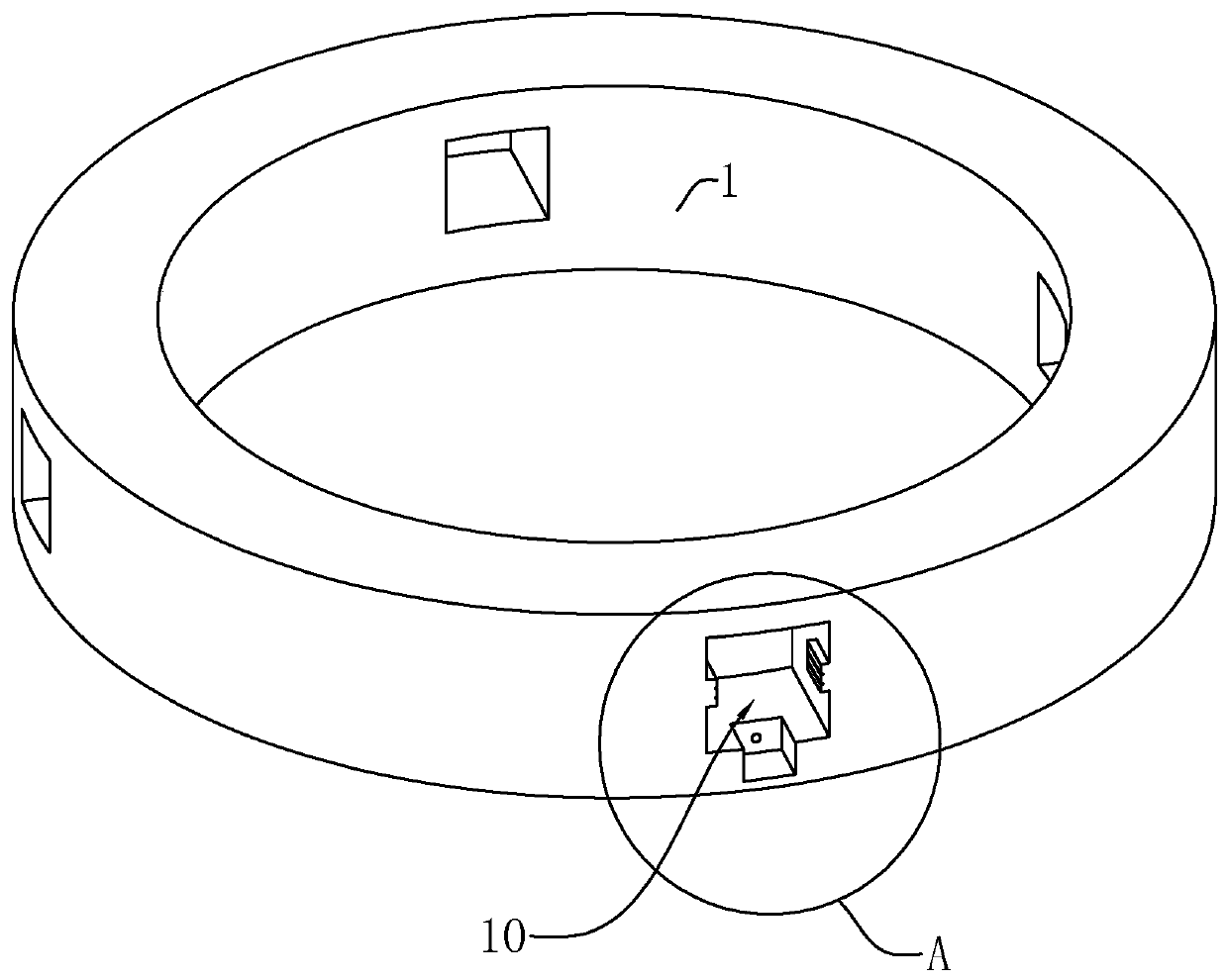

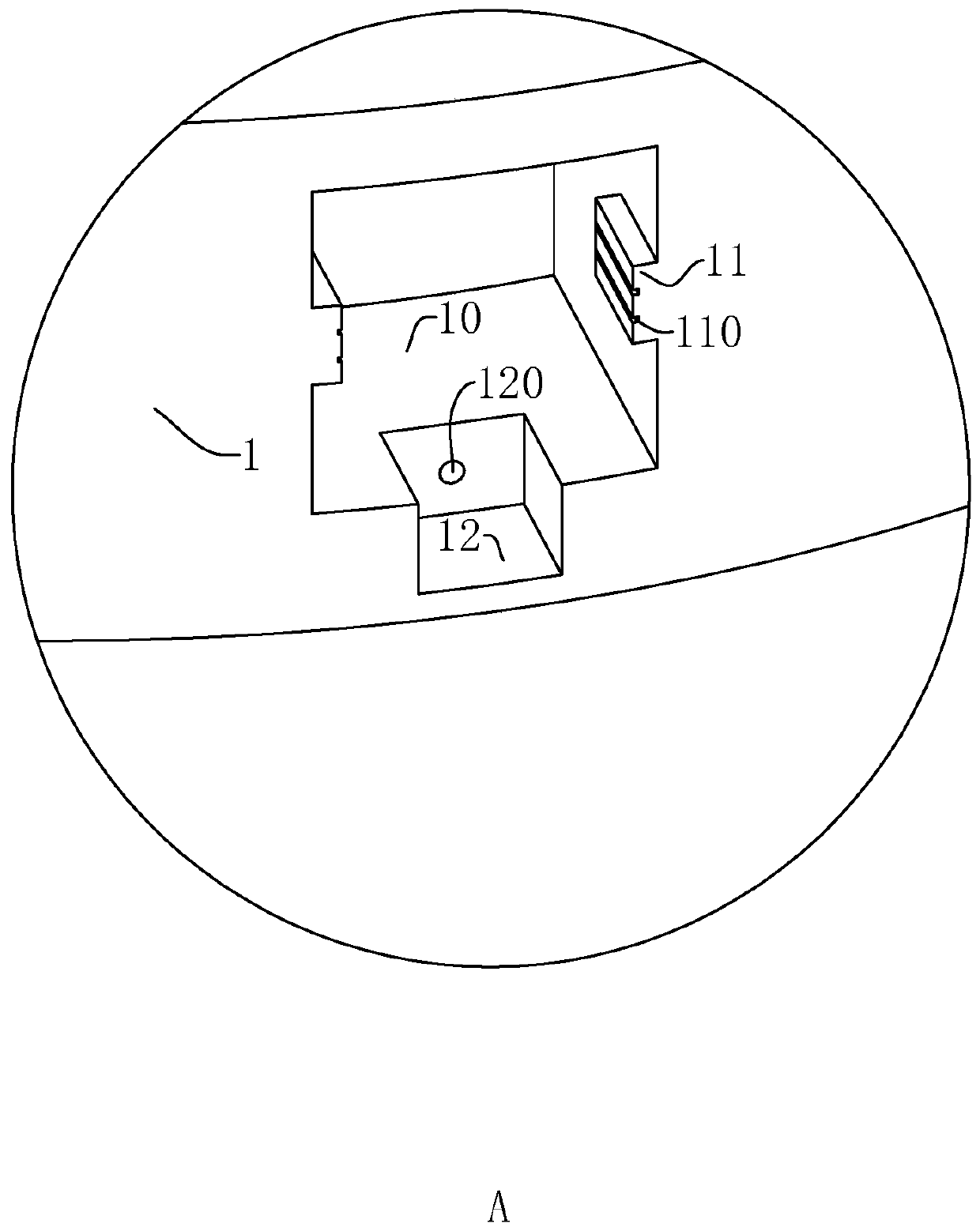

[0037] to combine figure 2 , image 3 , the shell 2 is connected with the ring base 1, the ring base 1 is provided with an inserting hole 10 for inserting the shell 2, the two sides of the insulating shell 21 are provided with reinforcing grooves 210, and the inner wall of the inserting hole 10 is integrally connected with a reinforcing groove 210 embedded in the clamping block 11, the bottom of the reinforcement groove 210 protrudes outwards with a clamping rib 211, and the clamping block 11 is provided with a clamping groove 110 that cooperates with the clamping rib 211, and the insulating shell 21 is away from One end of the conductive pipe 20 is integrally connected with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com