Automatic assembly machine for external magnetic rotor of magnetic pump

A technology of external magnetic rotor and automation group, which is applied in the field of magnetic pumps, can solve the problems of not using an assembly machine, high production cost, and long production time, and achieve the effects of saving manpower, good clamping stability, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

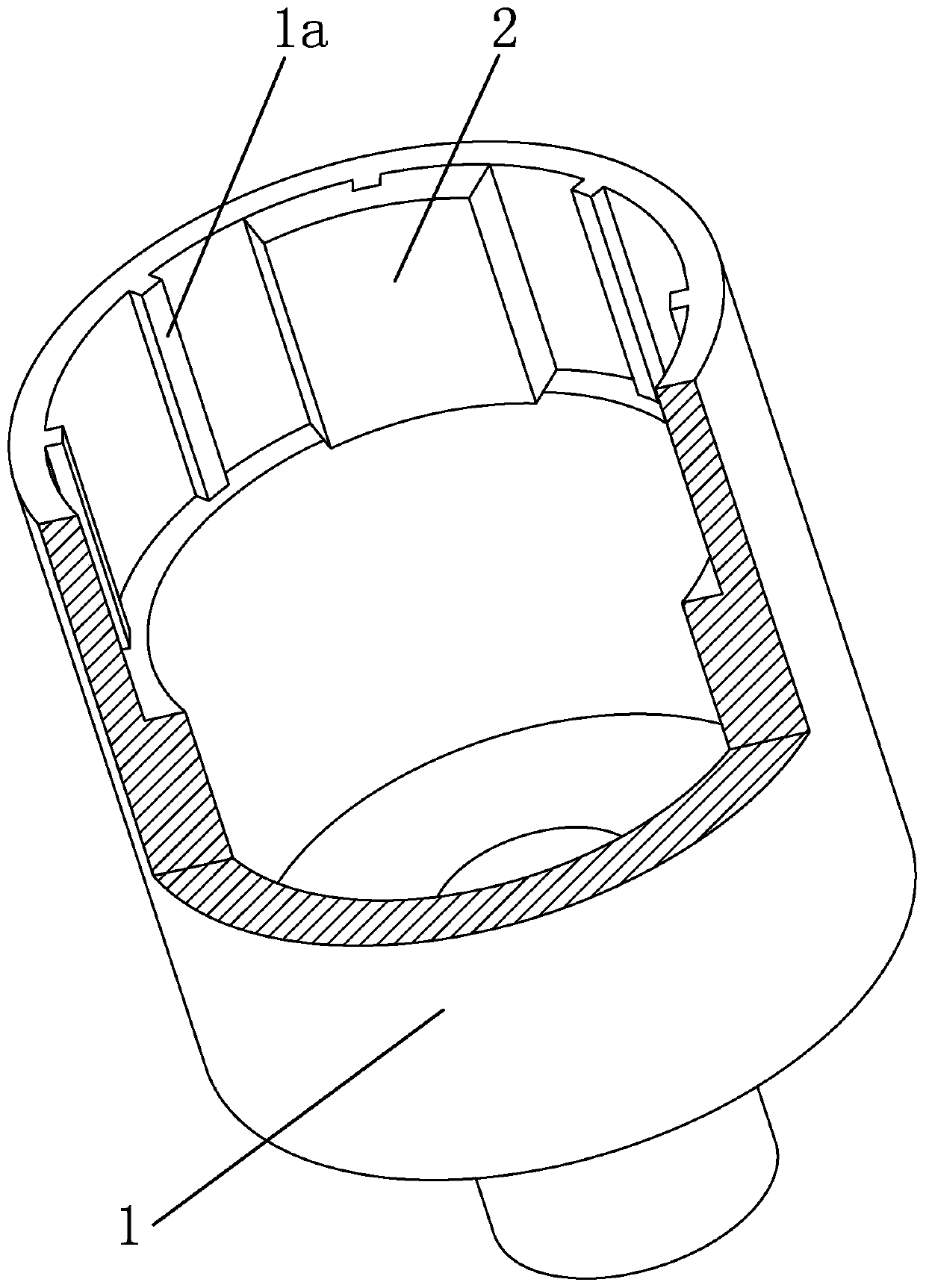

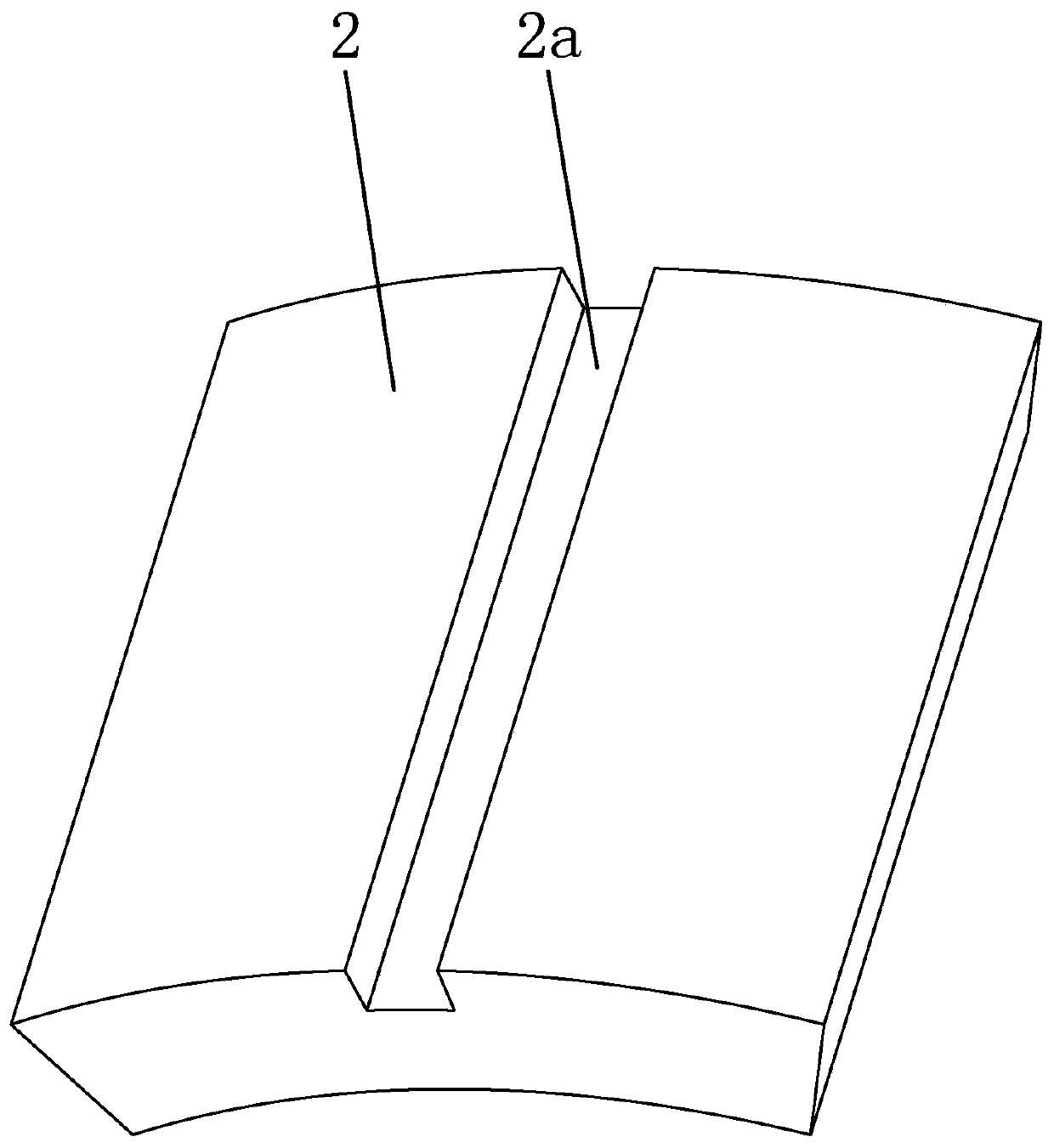

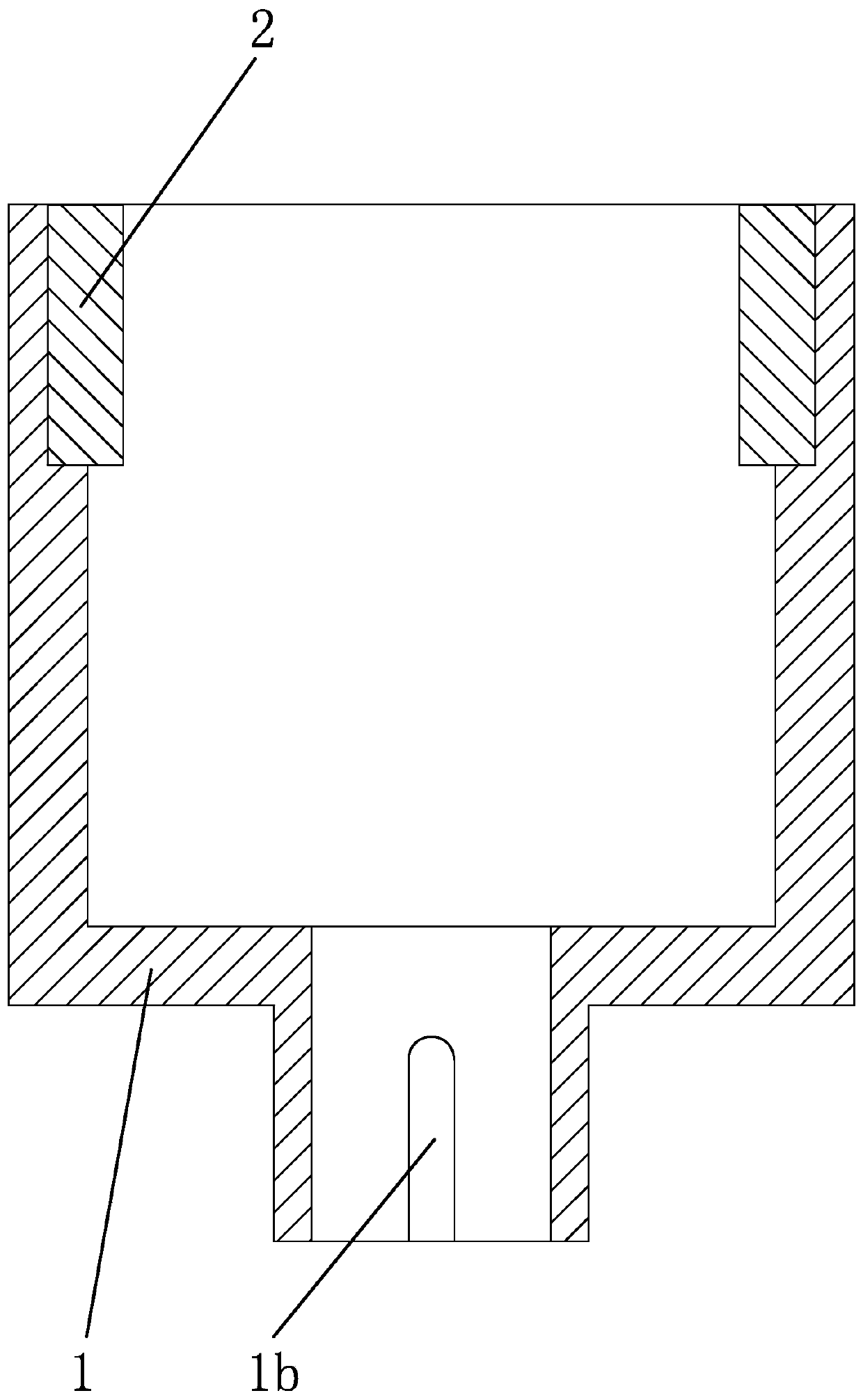

[0041] Such as Figure 1-Figure 11 As shown, the automatic assembly machine for the outer magnetic rotor of the magnetic pump, the outer magnetic rotor includes a rotor base 1 and magnetic tiles 2. In this embodiment, the outer magnetic rotor is an existing product on the market, wherein the top of the rotor base 1 A boss 1a is vertically opened on the inner side wall, a keyway 1b is vertically opened on the inner side wall of the bottom end of the rotor seat 1, and a groove 2a is vertically opened on the outer side wall of the magnetic tile 2, and the boss 1a is matched with the groove 2a, In this embodiment, the outer side wall of the magnetic tile 2 is also fixed on the inner side wall of the rotor base 1 by glue, the N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com