An inertial rotary piezoelectric motor

A technology of rotating pressure and electric motors, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problems of low motion efficiency, large friction damage, etc. The effect of high efficiency, large deformation and simple preloading method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

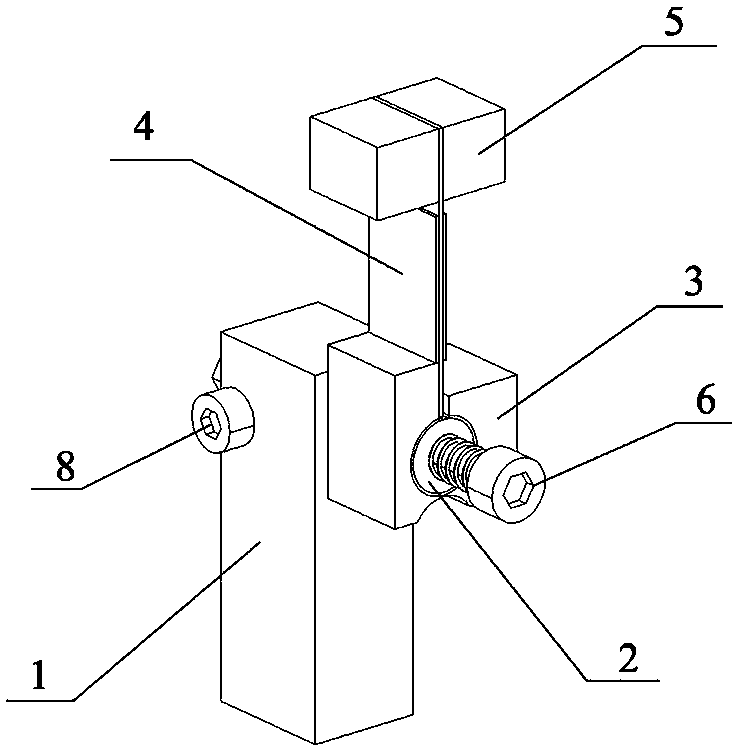

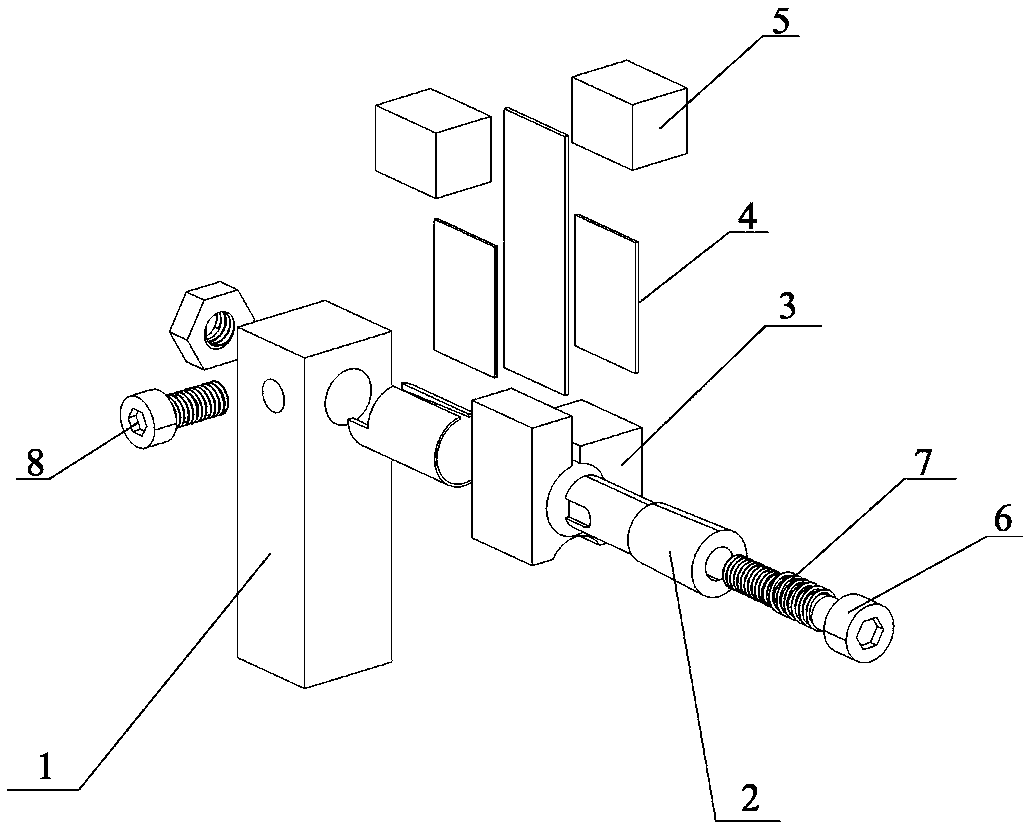

[0033] see figure 1 and figure 2 , an inertial rotary piezoelectric motor includes a base 1, a rotor mechanism and a pretension mechanism.

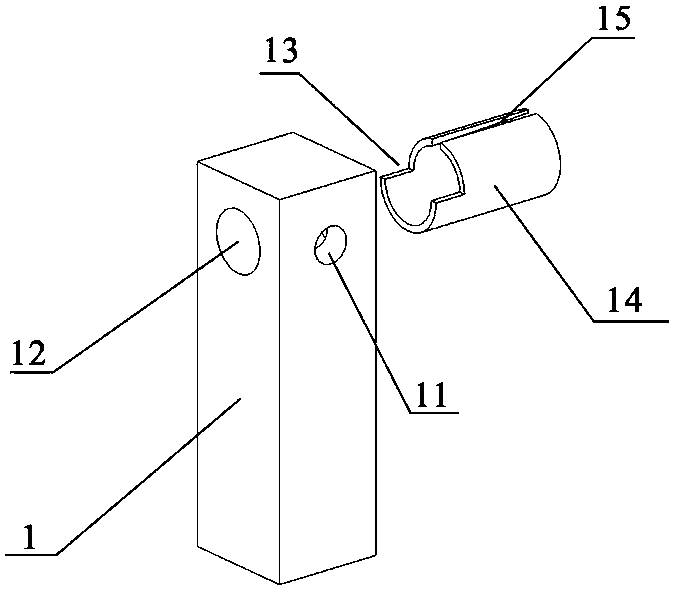

[0034] see image 3 , the base 1 is a square prism, and the top of the base 1 is provided with mounting holes 12 through the corresponding two sides, and the side surface of the base 1 corresponding to the mounting holes 12 is fixedly connected with the mounting pipe 14, and the pipe hole of the mounting pipe 14 is a conical hole. And the small-diameter end of the conical hole corresponds to the mounting hole 12 on the base 1, the mounting pipe 14 is in the shape of a cantilever, and the large-diameter end of the conical hole is an outer port. The other side of the upper part of the base 1 is provided with a threaded hole 11, and the threaded hole 11 and the mounting hole 12 are connected at 90 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com