Workpiece collection point unit and method for assisting the machining of workpieces

A collection point, workpiece technology, applied in the direction of metal processing, manufacturing tools, transportation and packaging, etc., can solve the problems of hindering the process, wrong storage of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

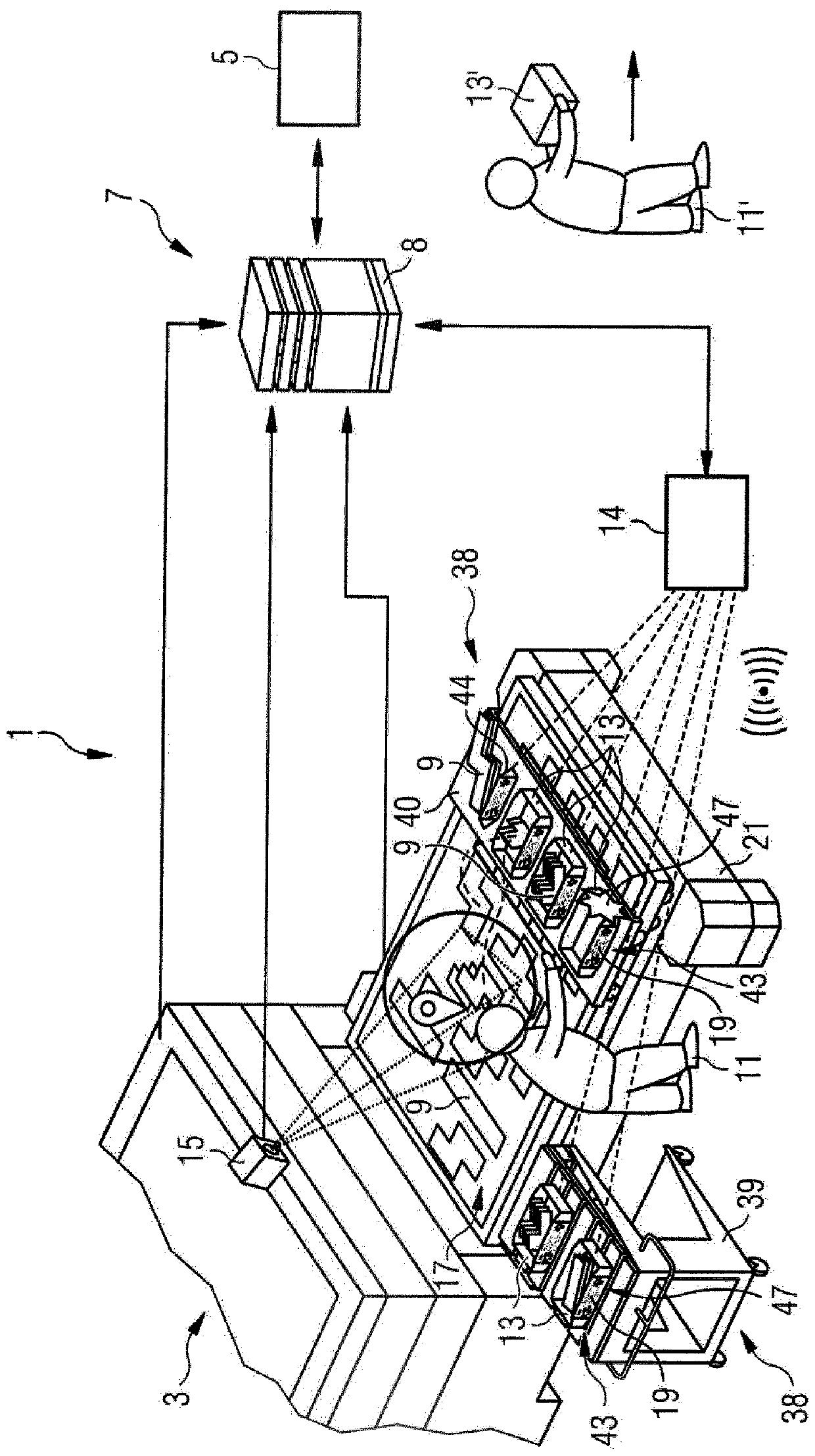

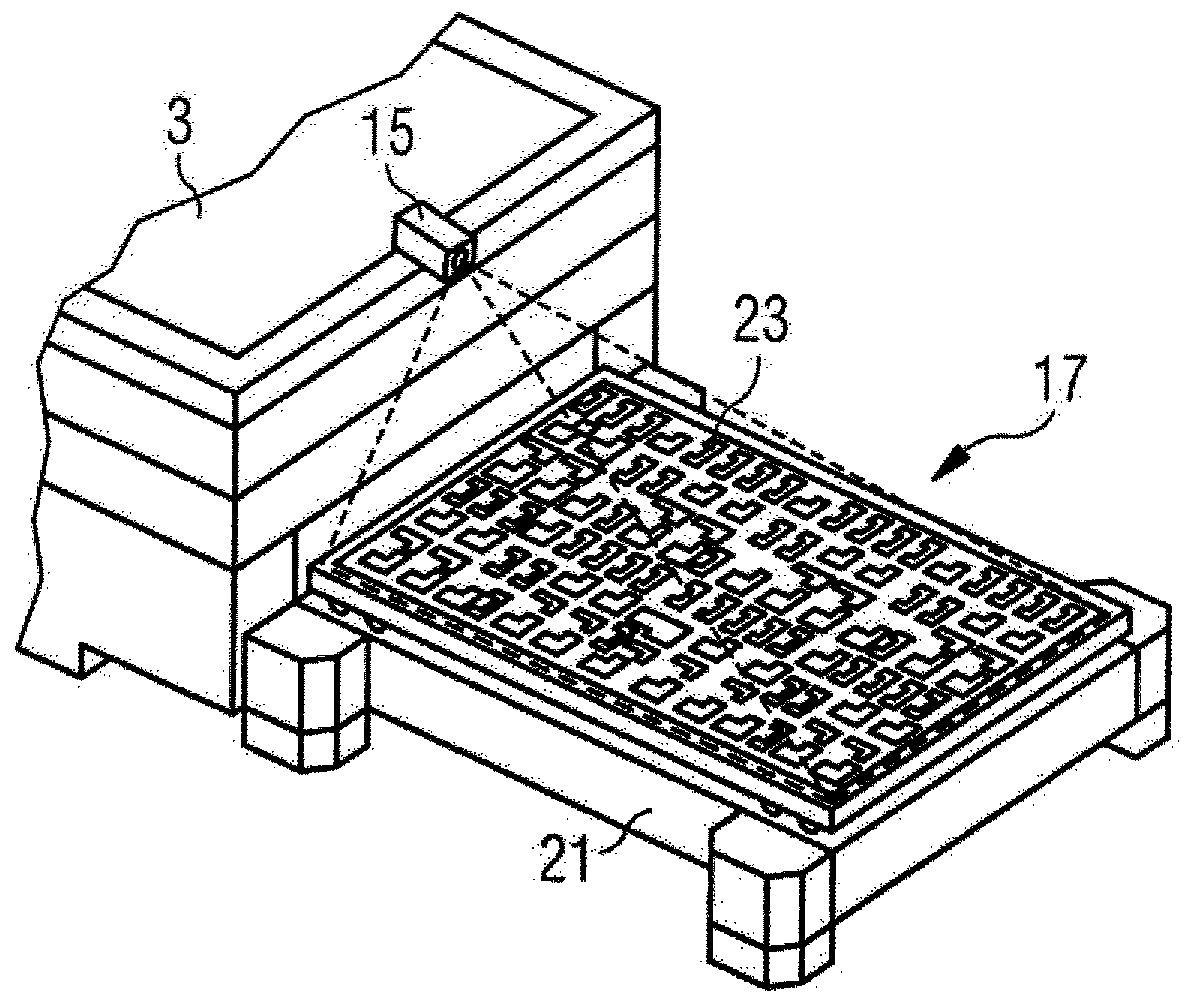

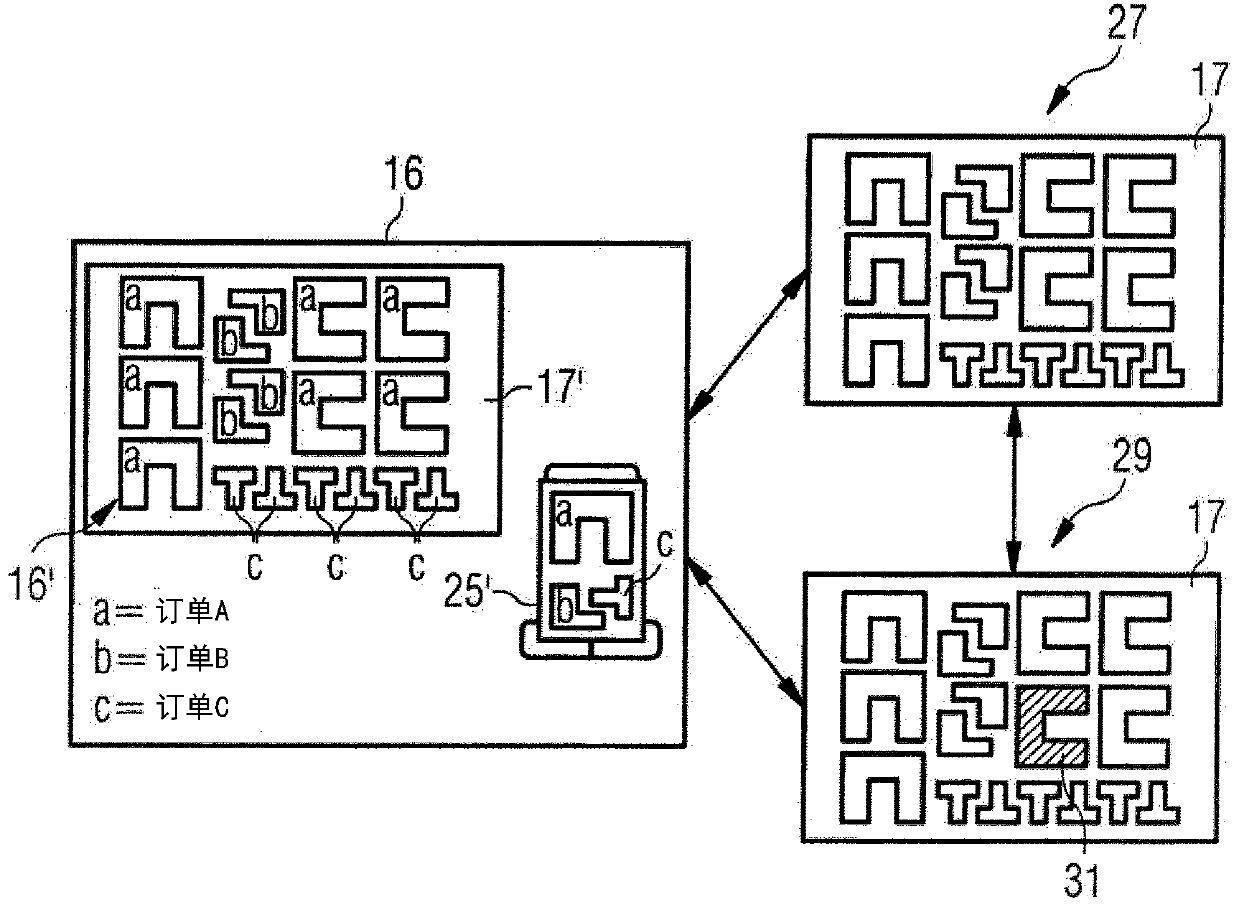

[0064] The aspects described here are based in part on the recognition that in laser cutting or stamping platform machines, the presence of an accurate cutting plan combined with imaging sensing of the sorting table on which the resulting cuts are placed can be used to assist in sorting. selected process and used to obtain information suitable for other process flows.

[0065] The approach described here relates in particular to a flat-plate plant which produces workpieces for subsequent processing steps from so-called sheet metal (starting metal sheets with a predetermined thickness and predetermined area dimensions) by means of stamping or cutting. In particular, the workpiece can be converted into a freely selectable flat shape in the case of flat-bed machines by the processing of sheet metal which is made very flexible by the use of a laser. Subsequent bending and welding processes produce three-dimensional products. In such laser cutting or stamping flatbed machines, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com