Chip center positioning fixture

A center positioning and chip technology, which is applied to coatings and devices for coating liquids on surfaces, etc., can solve the problems of long time, cumbersome process, high procurement cost, etc., to achieve simple operation, short time, and reduce misoperation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] It should be noted in this application that the term "multi-scale" used in this application refers to multiple sizes of chip diameters.

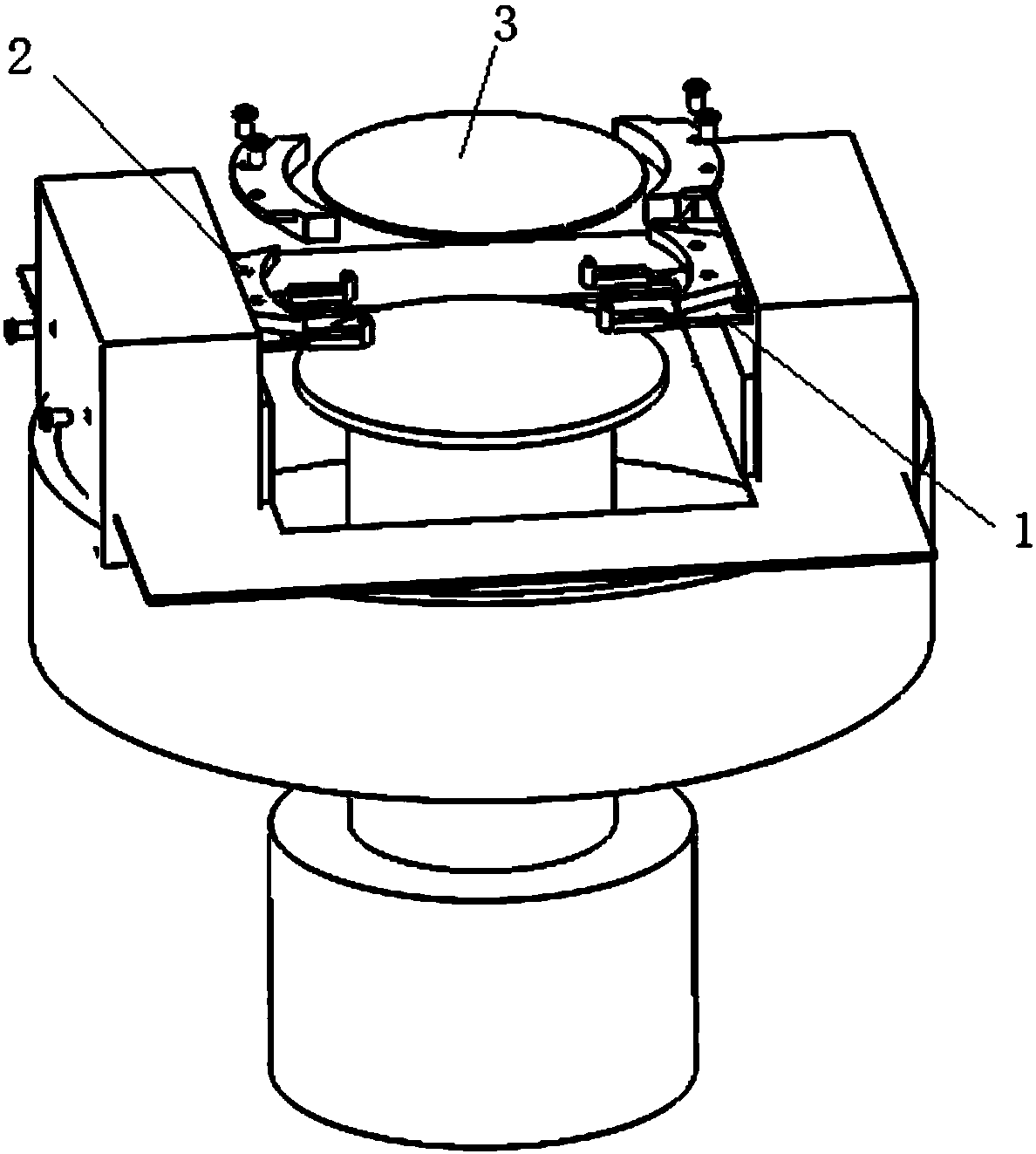

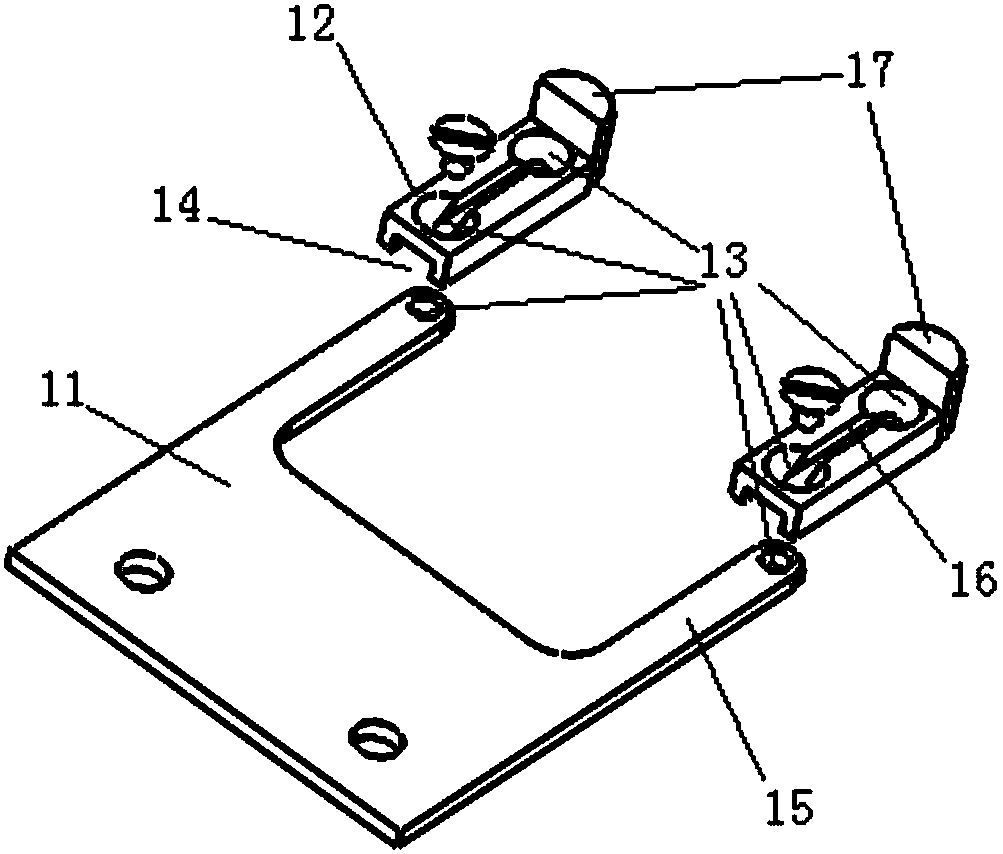

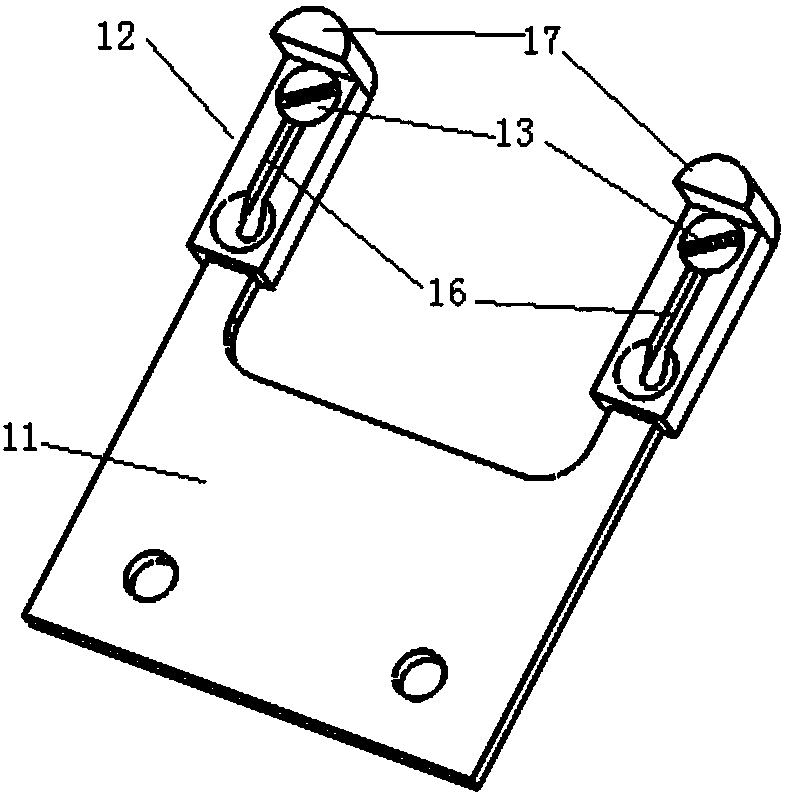

[0036] like figure 1 As shown, it is a schematic diagram of the assembly of the chip center positioning fixture of the present invention, including a support frame 1 and a clamping plate 2, the support frame 1 is placed on the bottom of the chip 3 for supporting the chip 3, and the clamping plate 2 is used for clamping the chip 3 The outer edge of the chip 3 is centered to ensure that the chip 3 will not be separated from the vacuum-adsorbed wafer table 4 due to centrifugal force when rotating at high speed; wherein, the support frame 1 and the clamping plate 2 are fixedly installed on the support block 5, Due to the step setting of the support block 5, the clamping plate 2 is located above the support frame 1. In addition, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com